Push type pencil sharpener

A pencil sharpener and push-type technology, which is applied in printing, sharpening devices, office supplies, etc., can solve the problems of reducing the service life of cutting mechanisms, cutting force cannot be adjusted, time-consuming and labor-intensive, etc., to reduce wear and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0036] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

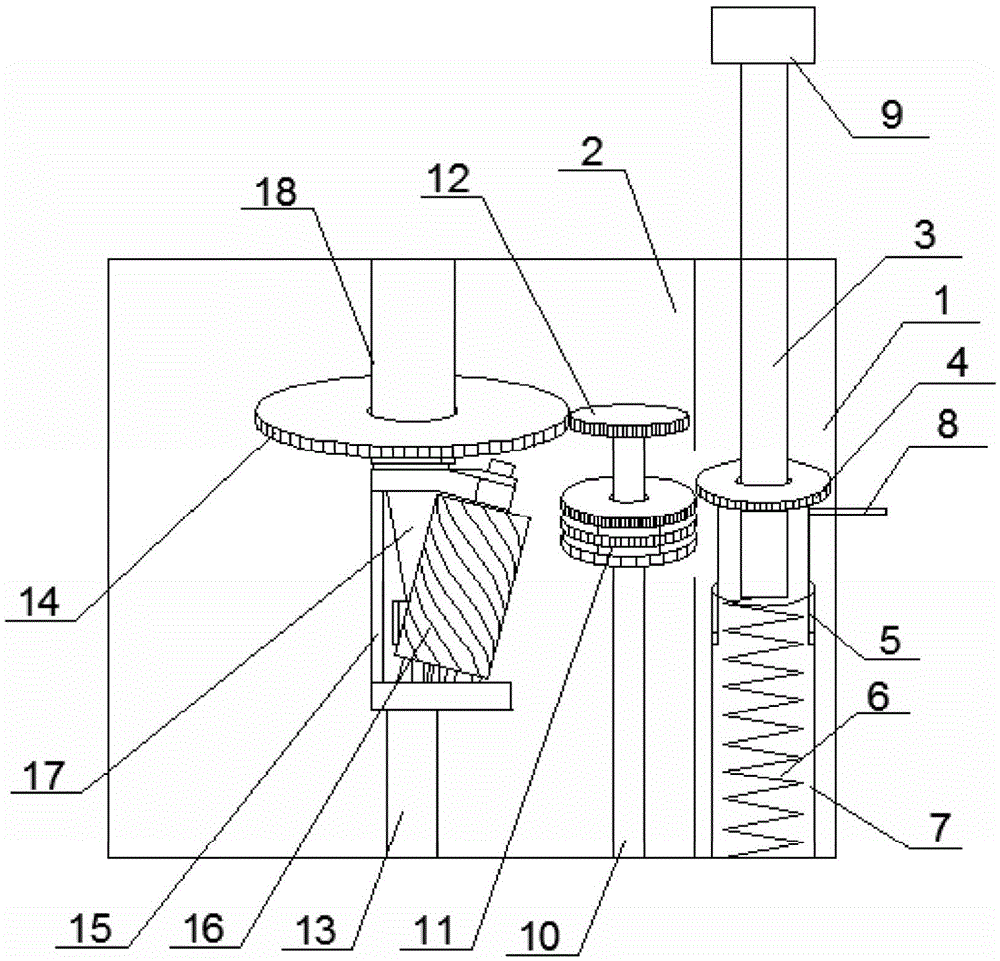

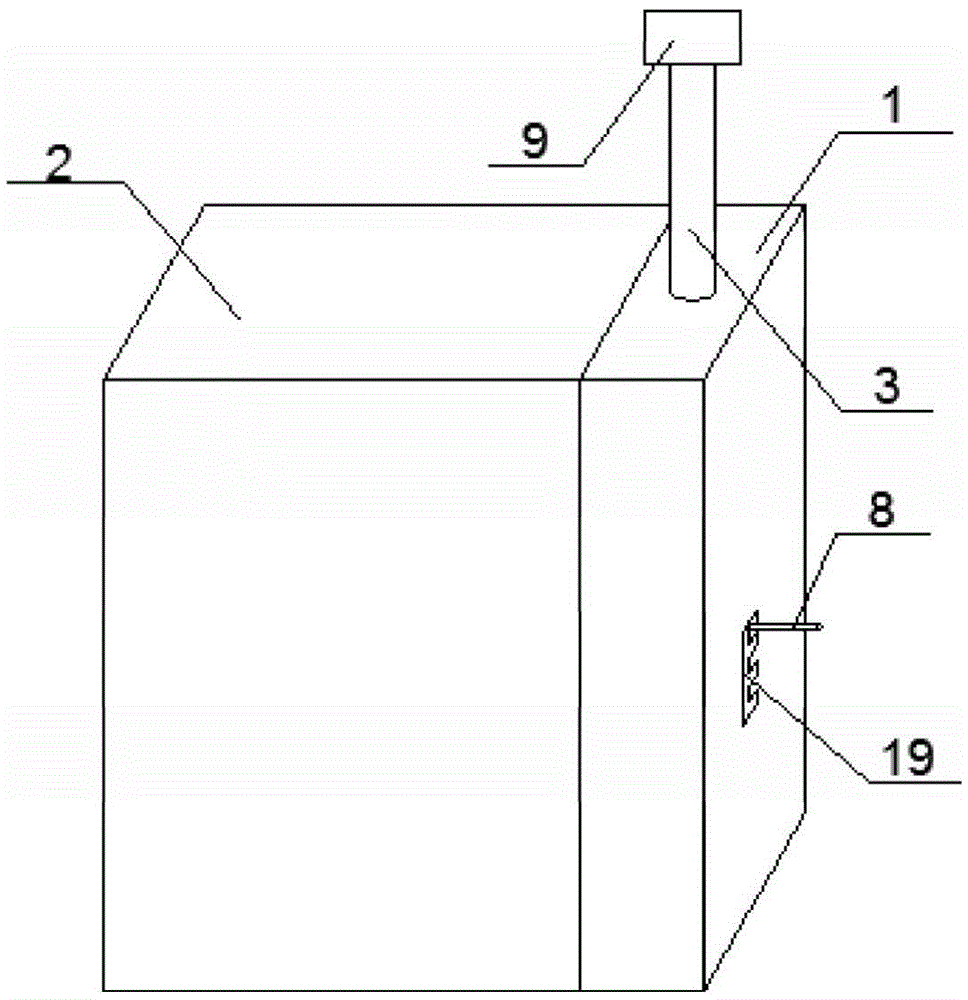

[0037] Such as Figure 1~4 As shown, the present invention provides a push-type pencil sharpener, which includes:

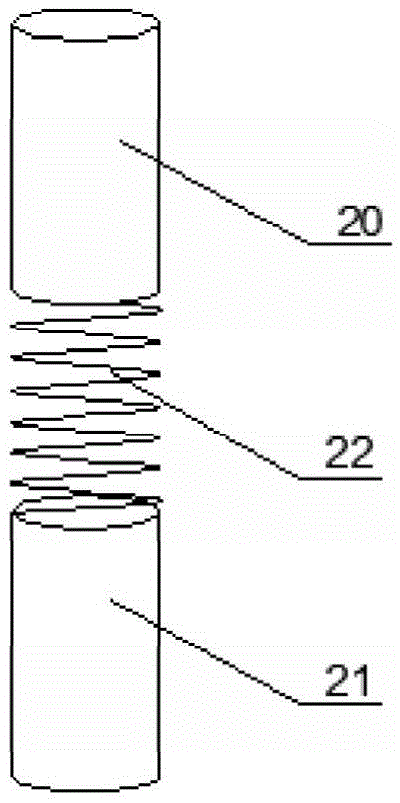

[0038] The housing has a hollow cuboid structure, and a vertical partition is provided in the middle of the housing, and the partition divides the housing into two spaces on the left and right, which are respectively the first space 1 and the second space 2, The middle part of the partition is provided with a first through hole, so that the first space 1 and the second space 2 are partly communicated, and the part of the housing located in the first space 1 and opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com