Double-blade hoisting equipment and method

A kind of hoisting equipment and double-blade technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inconvenient hoisting of the impeller, and achieve the effect of convenient hoisting, stable grounding, and reduced hoisting space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

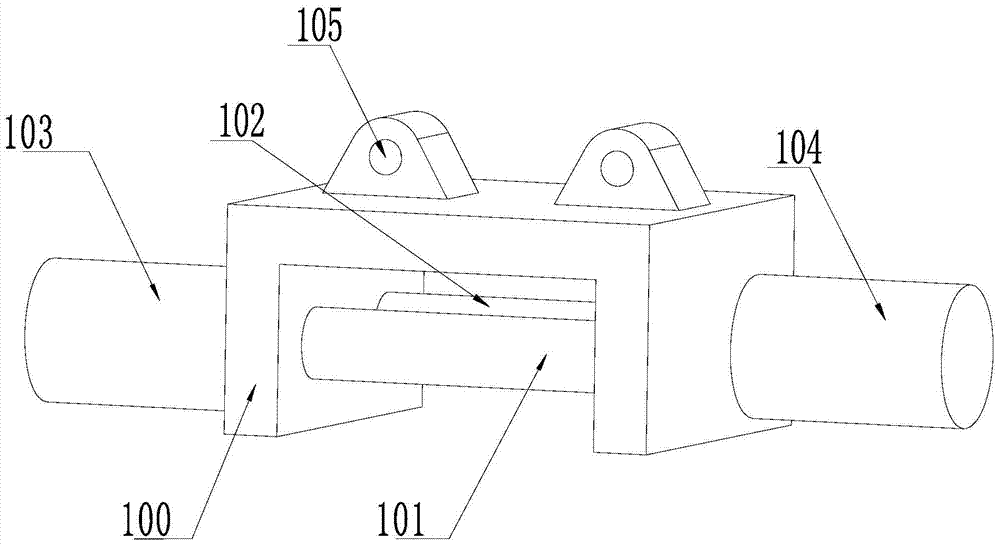

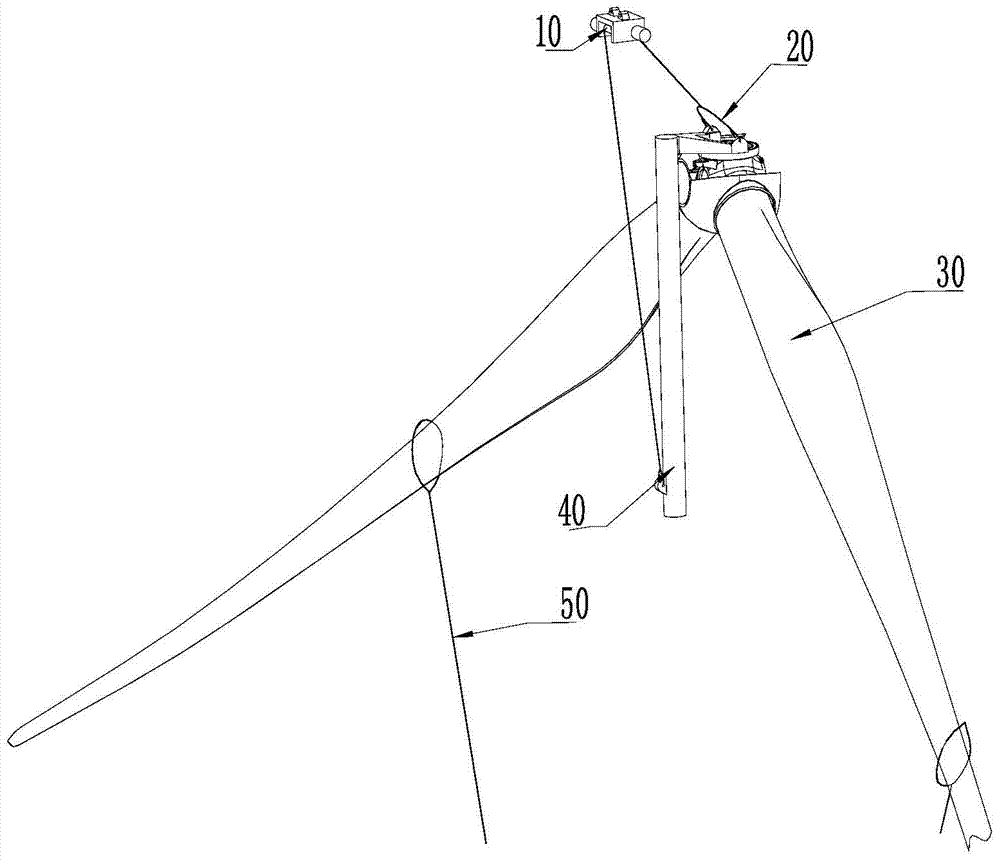

[0027] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a double-blade hoisting device, which is used for hoisting the combination of the hub and the double blades. Put mechanism 10 and spreader 40. Wherein, the lifting adjustable mechanism is connected with the steel cable retracting mechanism 10 for controlling the lifting of the steel cable retracting mechanism 10 . The lifting adjustable mechanism can be the main hook on the offshore wind turbine installation ship, which can lift heavy objects and adjust the lifting of heavy objects according to the needs of actual working conditions.

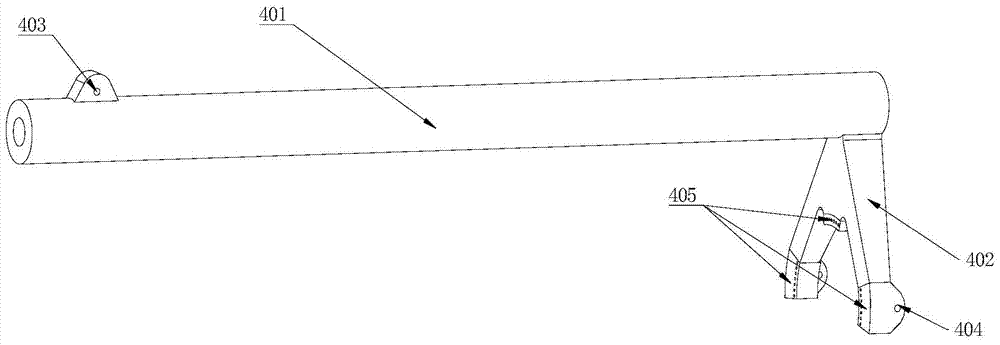

[0028] Double-blade 30 hoisting equipment The spreader 40 of the double-blade hoisting equipment has a long arm 401 and a short arm 402 perpendicular to the long arm 401, and the short arm 402 is connected to the combination of the double blades of the hub, mainly used as a spreader 40 When docking with the double blades 30, the docking parts of the...

Embodiment 2

[0045] Such as image 3 and Figure 4 As shown, another aspect of the embodiment of the present invention provides a double blade hoisting method, comprising the following steps:

[0046] S1. Connect the lifting adjustable mechanism with the steel cable retractable mechanism 10, connect the steel cable retractable mechanism 10 with the spreader 40, start the lifting adjustable mechanism, and control the lifting adjustable mechanism to lift the steel cable retractable mechanism 10 and the hanger 40 that is connected with the steel cable retracting mechanism 10.

[0047] Of course, before step S1, it is necessary to disassemble the damaged single blade (manual operation), and clean the end surface of the pitch bearing of the impeller before disassembly, especially the threaded holes on the bearing. The damaged part of the blade 30 is also dismantled together.

[0048] When connecting the lifting adjustable mechanism and the steel cable retractable mechanism 10, it is only nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com