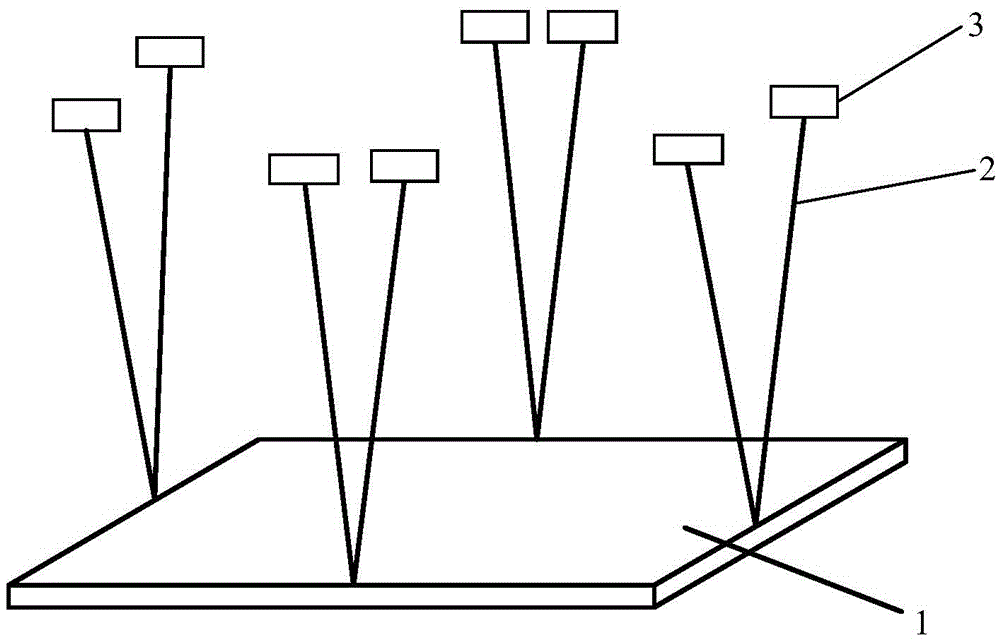

Multi-rope lifting system and method

A sling and one-to-one correspondence technology, which is applied in the field of multi-rope lifting systems, can solve the problems of easily injuring on-site personnel and facilities, reducing the service life of equipment, and economic losses, so as to avoid non-level overweight, reduce the probability of accidents, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

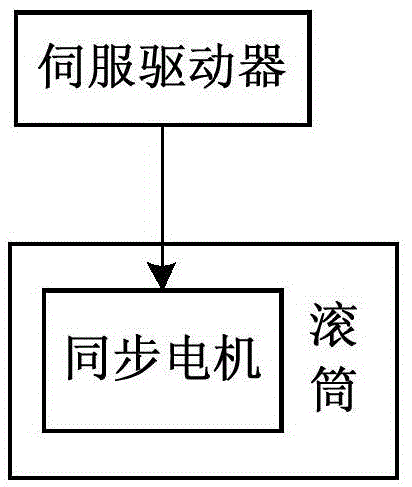

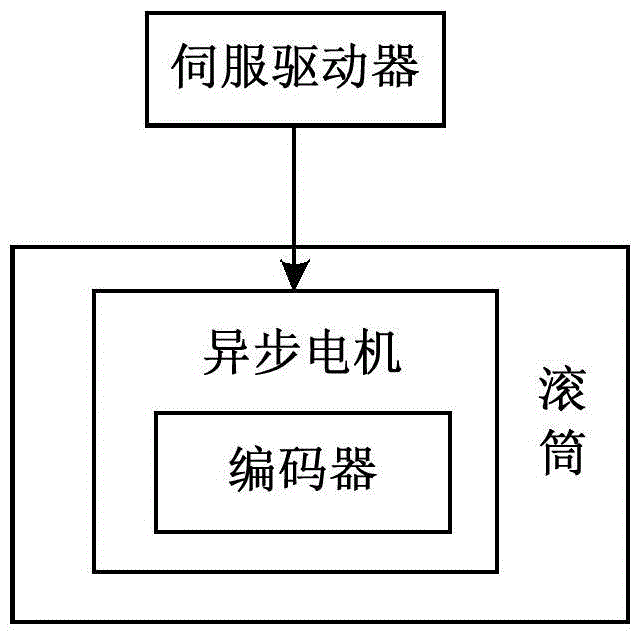

[0023] The specific implementation is as follows: During the lifting process, the controller detects the torque of each roller control mechanism. Since a synchronous motor is used in this embodiment, the current output to the motor is proportional to the torque, that is to say, the controller According to the current output to each roller control mechanism, the magnitude of the torque of the roller control mechanism can be measured. Then, the controller judges whether the torques of the detected drum control mechanisms are the same, and judges whether there is a non-level phenomenon in the unloaded spreader controlled by the N suspension ropes. If it is detected that the torques of the drum control mechanisms are the same, then, The unloaded sling does not have non-horizontal phenomenon, that is, it is in a horizontal position, and the controller sends a position control signal for pulling the rope to the N roller control mechanisms; if it detects that the torque of each roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com