Water supply weft insertion device of water jet loom and water supply method thereof

A water-jet loom and weft insertion device technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of fragile parts, low efficiency, instability, etc., to improve production efficiency, facilitate installation and disassembly, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

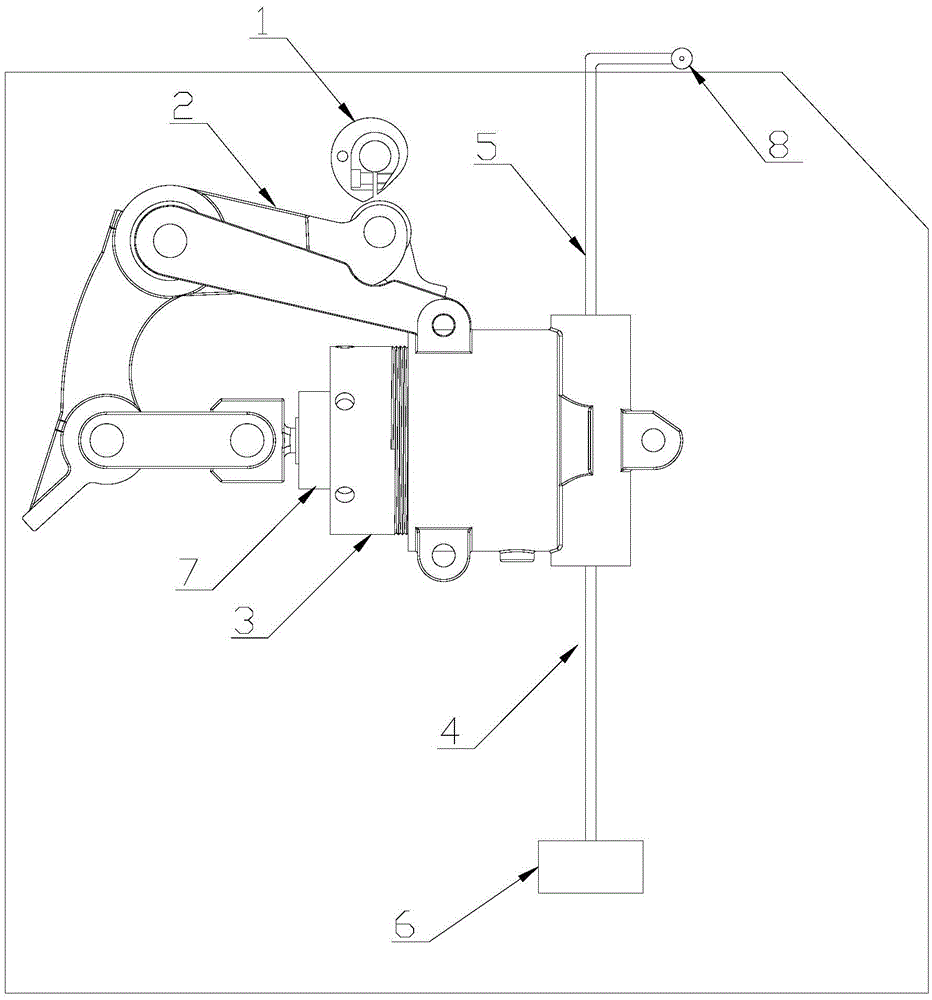

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

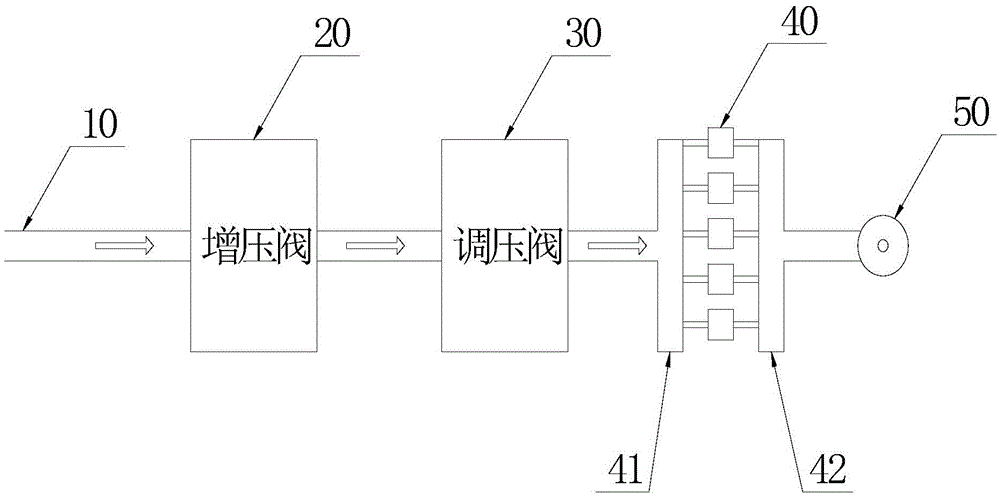

[0020] see figure 2 , a water supply weft insertion device for a water jet loom, comprising a water supply pipe 10, a booster valve 20, a pressure regulating valve 30, N solenoid valves 40 and nozzles 50, where N is a natural number greater than 1. The number of solenoid valves 40 in this embodiment is 5, that is, N=5.

[0021] The water inlet of the booster valve 20 is connected to the water source through the water supply pipe 10, the water outlet of the booster valve 20 is connected with the water inlet of the pressure regulating valve 30, and the water outlet of the pressure regulating valve 30 is connected with the water inlets of N electromagnetic valves 40 respectively. , the water outlets of the N solenoid valves 40 communicate with the nozzles 50 respectively. In order to facilitate the connection, and to connect N electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com