Construction method for erecting and installing bridge pier top block by adopting floating crane

A construction method and technology for bridge piers, applied in the direction of bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of high risk, tight time, quality and speed cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] This embodiment discloses a construction method in which the top block of a bridge pier is erected and installed by means of a floating crane. It is an improvement over the shortcomings of using a bridge erecting machine to hoist the top block of a pier in the background technology. It includes the following steps:

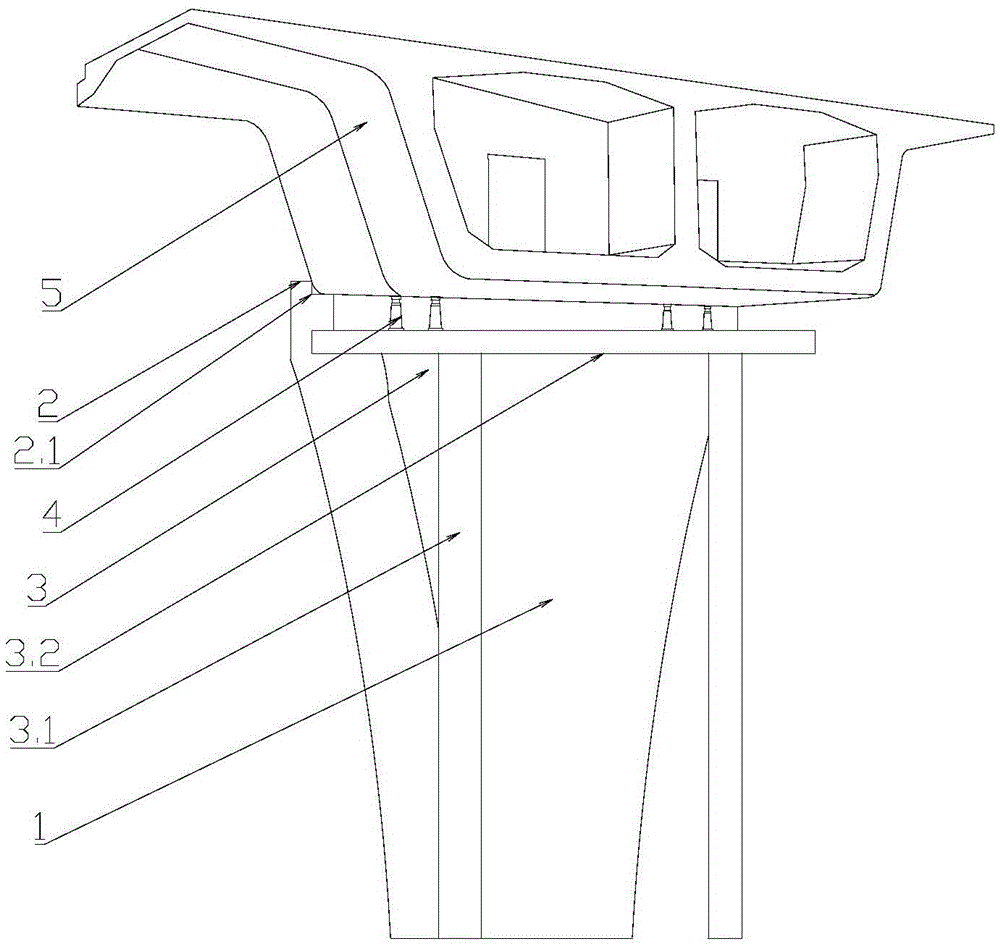

[0019] 1) A permanent support 2 is installed on the top of the pier body 1, a temporary support 3 is erected on the side of the pier body 1, and several three-way adjustment jacks 4 are arranged on the top surface of the temporary support 3;

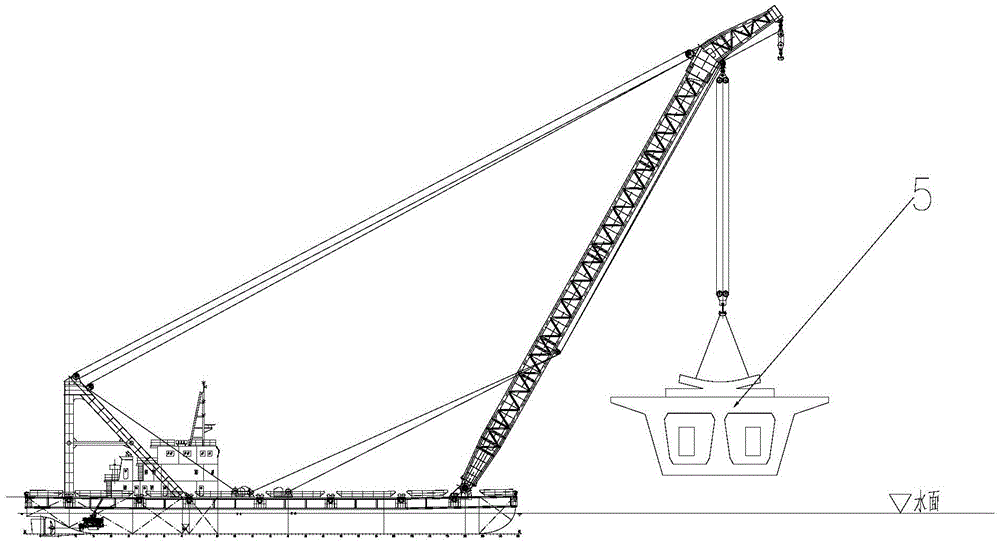

[0020] 2) Reference figure 1 Firstly, the pier top block 5 is lifted above the top of the pier body 1 by floating hoisting. At this time, the vertical and horizontal axes of the pier top block 5 are roughly aligned with the vertical and horizontal axes on the pier top. The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com