Temperature and humidity control system for textile workshop

A temperature and humidity control and workshop technology, applied in the field of textile production, can solve the problems of increasing textile production costs, wasting manpower, and uneven quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

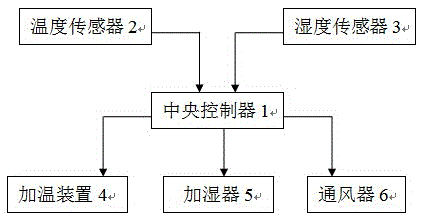

[0007] as attached figure 1 As shown, the present invention is made up of main controller 1, temperature sensor 2, humidity sensor 3, heating device 4, humidifier 5, ventilator 6. The temperature sensor 2 and the humidity sensor 3 are installed in the textile workshop and connected to the main controller 1 for monitoring the temperature in the textile workshop and feeding back the monitoring results to the main controller 1 . The main controller 1 then controls the heating device 4, humidifier 5 and ventilator 6 according to the obtained monitoring data to make the temperature and humidity in the textile workshop reach the state most suitable for production. This process is completed automatically without manual participation, so The invention is convenient to use and stable in performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com