A Method for Measuring Thin Ice Using Capacitive Thin Ice Sensor with Insert Finger Microstructure

A microstructure and capacitive technology, applied in the field of sensor and sensor technology, can solve the problems of poor accuracy, low detection sensitivity, difficult installation, etc., and achieve the effect of increasing measurement accuracy, reducing misjudgment of icing, and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

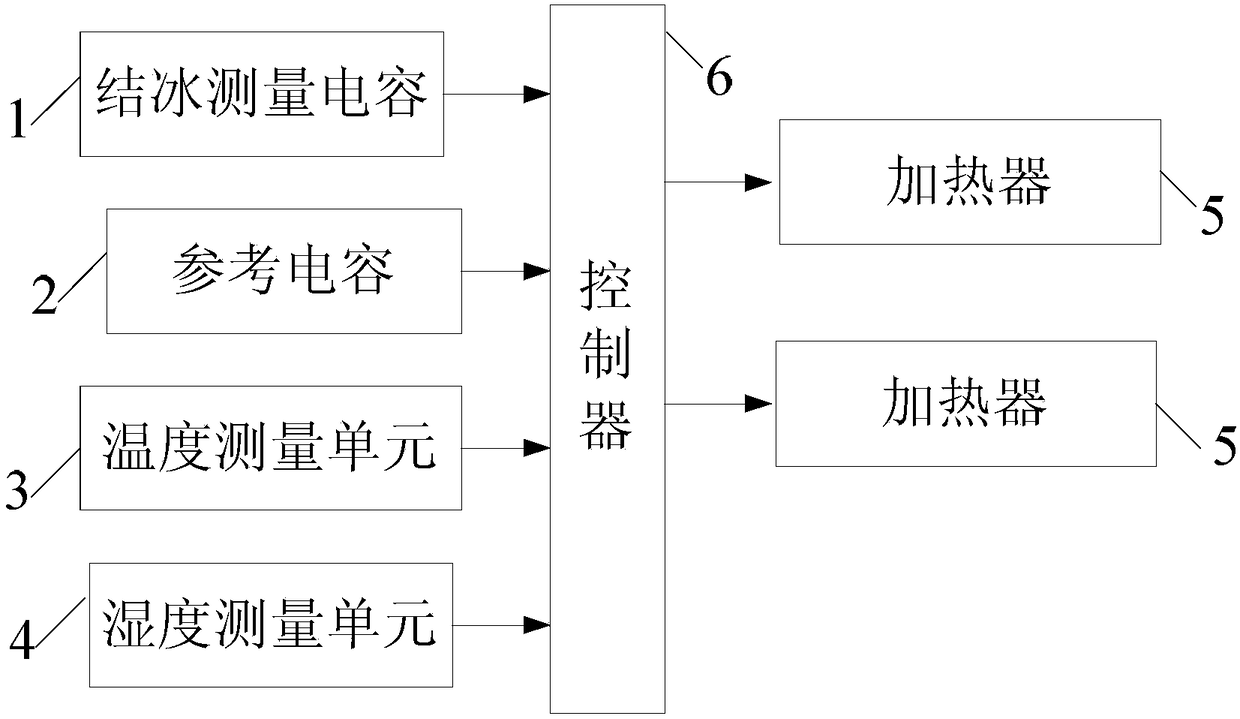

[0020] Specific implementation mode one: refer to figure 1 and figure 2 Describe this embodiment in detail, one of the methods described in this embodiment adopts

[0021] A method for measuring thin ice with a microstructure capacitive thin ice sensor comprising the following steps:

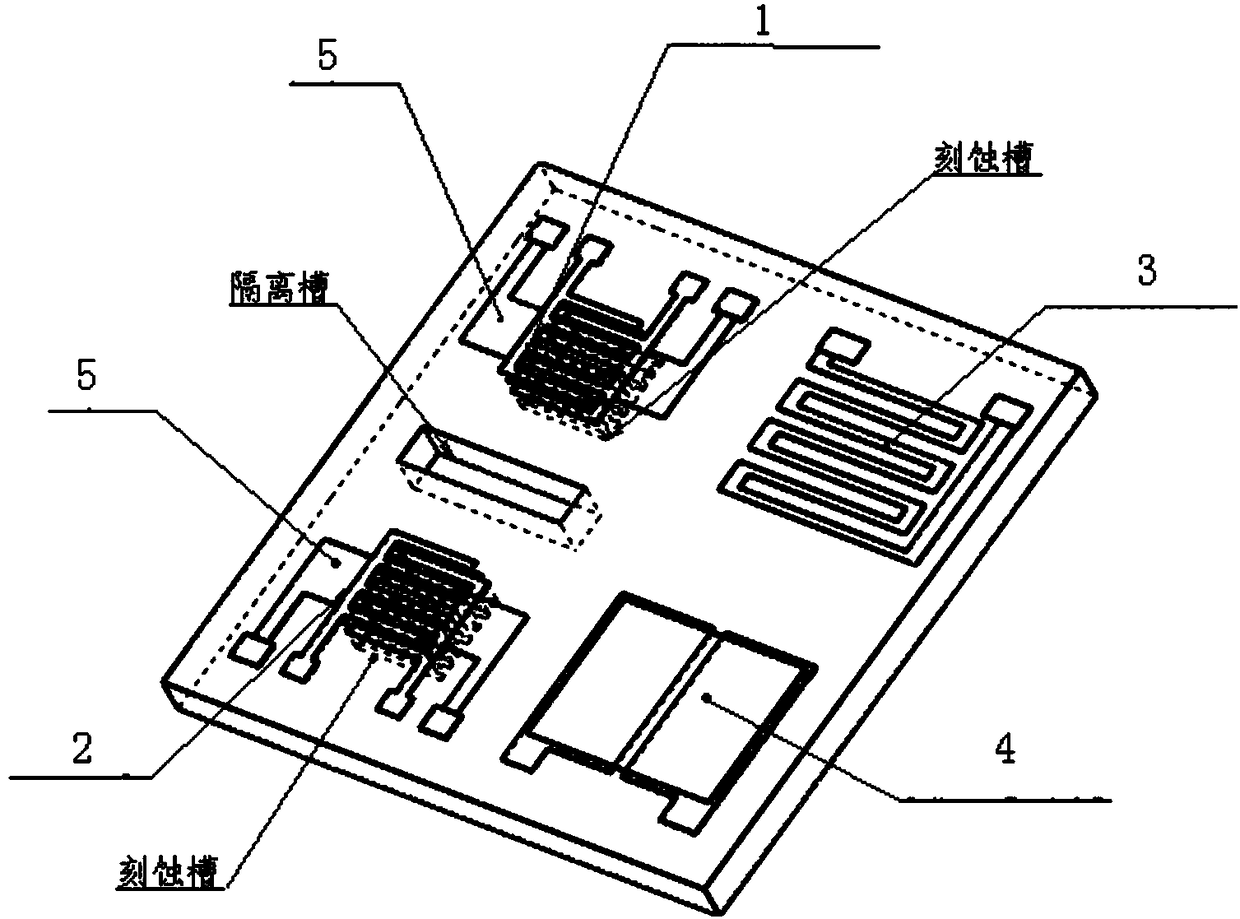

[0022] Step 1. Set the reference capacitor 2, the icing measurement capacitor 1, the temperature measurement unit 3 and the humidity measurement unit 4 on an N-type silicon chip, and use the reference capacitor 2 to measure the capacitance of the air environment; use the icing measurement capacitor 1 to measure Capacitance on the surface of the aircraft; temperature measurement unit 3 is used to measure the temperature of the air; humidity measurement unit 4 is used to measure the humidity of the air;

[0023] Step 2, the controller 6 receives the data of the reference capacitor 2, the data of the icing measurement capacitor 1, the data of the temperature measurement unit 3 and the data of th...

specific Embodiment approach 2

[0026] Specific embodiment 2: This embodiment is a further description of the method for measuring thin ice using the microstructure capacitive thin ice sensor described in specific embodiment 1. In this embodiment, it also includes two heaters 5. Two heaters 5 are respectively arranged at the bottom of the reference capacitor 2 and the icing measurement capacitor 1 for heating, deicing and water removal of the measurement capacitor 1 and the reference capacitor 2 respectively, in preparation for the next measurement.

specific Embodiment approach 3

[0027] Specific embodiment three: This embodiment is a further description of a method for measuring thin ice using a microstructured capacitive thin ice sensor described in specific embodiment one. In this embodiment, the heater 5 is implemented by a heating resistor. , the temperature measurement unit 3 is realized by a platinum thin-film thermistor, and the humidity measurement unit 4 is realized by a humidity sensitive capacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com