Novel horizontal well fluid imager

A fluid imager and horizontal well technology, applied in boreholes/well components, measurement, earthwork drilling and production, etc., can solve problems such as large errors, water cut in arrays, inconvenient and easily damaged flowmeters, etc., to ensure the safety of well logging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

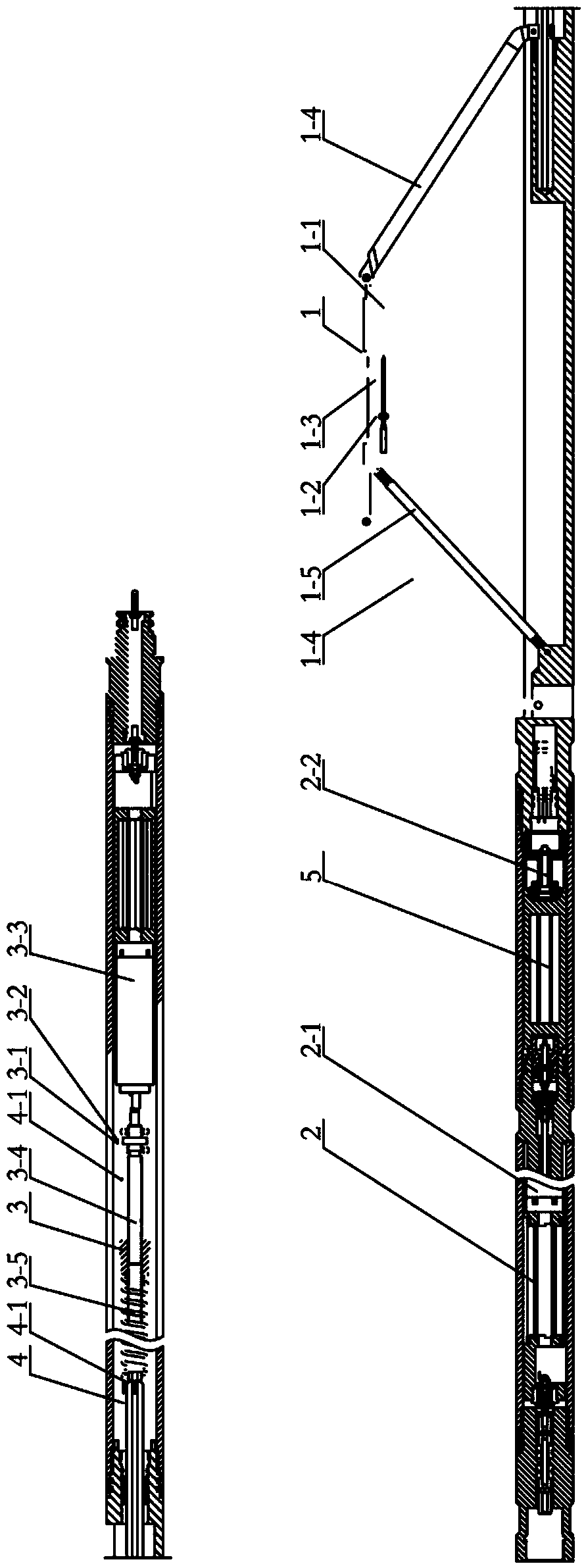

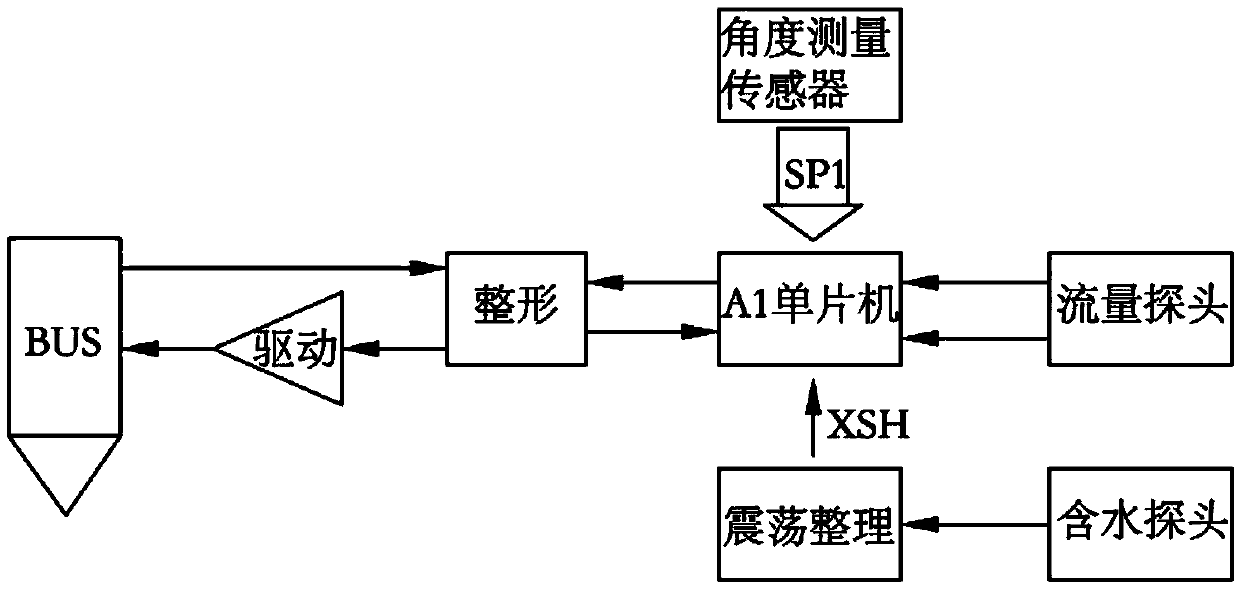

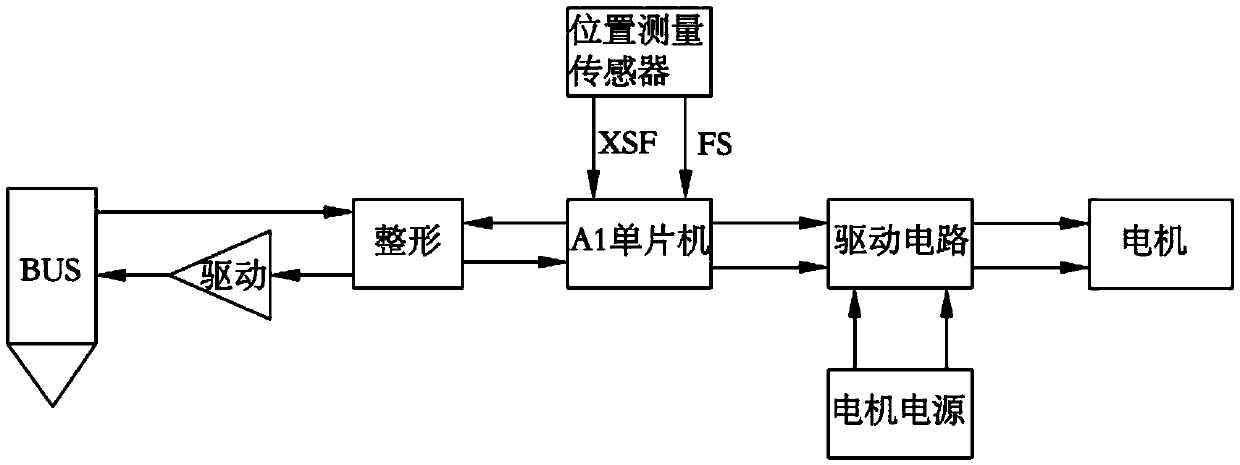

[0014] As shown in the figure, this new horizontal well fluid imager mainly includes a support arm sensor assembly, a support arm swing assembly and a support arm sensor pushing assembly. The support arm sensor assembly is used to measure the water holdup and flow rate, and then obtain wellbore fluid imaging results by processing the measured data; the arm swing assembly is used to turn the arm sensor assembly directly above the instrument, so as to ensure that the sensor assembly can measure the parameters of the fluid in the wellbore layer by layer The arm sensor push assembly is used to raise the arm sensor assembly to the required height, which can continuously scan the water holdup rate and flow rate of the fluid at different heights in the fluid section; the instrument is controlled separately by dual motors in the horizontal state The posture is correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com