Oil supplement and exhaust device for oil-immersed current transformer

A technology of current transformer and exhaust device, which is applied in the direction of transformer/inductor cooling, switchgear, electrical components, etc., and can solve problems such as manual oil replenishment and inability to remove air bubbles in the oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

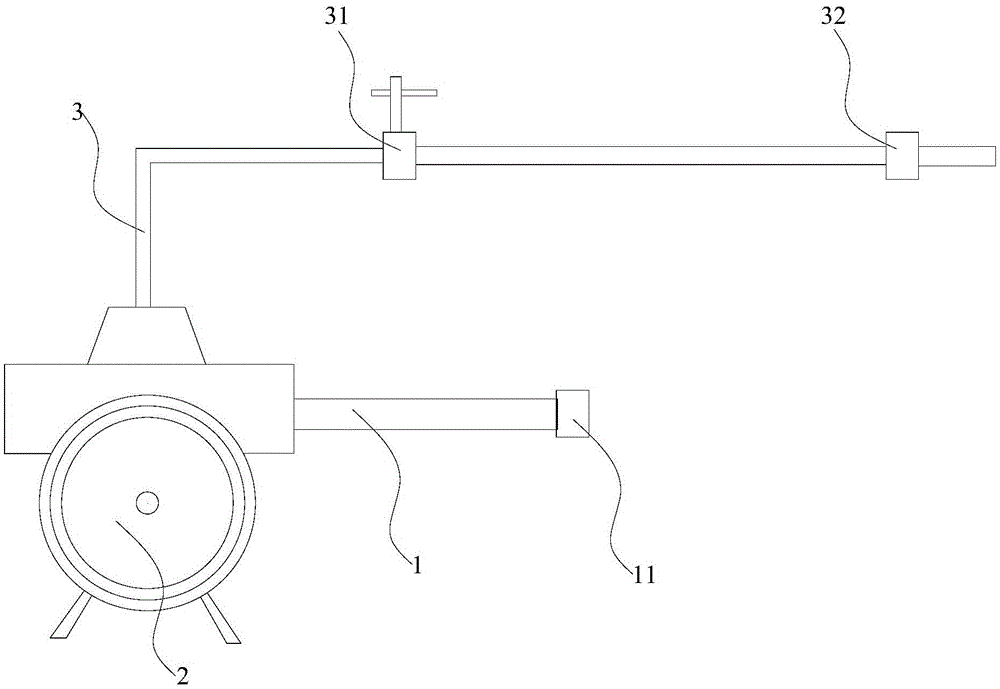

[0014] refer to figure 1 , an oil-immersed current transformer oil supply and exhaust device, characterized in that it includes an oil inlet pipeline 1 connected in sequence, an oil pump 2 equipped with a frequency converter, and an oil outlet pipeline 3; in addition, an oil inlet pipeline 1 is provided There is a first filter 11; and a flow regulating valve 31 and a second filter 32 are sequentially provided in the oil outlet pipeline 3 along the oil outlet direction. The first filter 11 is a filter screen, and the second filter 32 is an oil filter; any filter capable of filtering oil residue in the prior art can be used.

[0015] After the oil pump 2 is equipped with a frequency converter, that is, the power supply of the oil pump passes through the frequency converter first, and then supplies the oil pump after coming out of the frequency converter. Thereby the pump oil flow rate of oil pump 2 can quantitatively control by changing the power supply frequency; Just can cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com