Component mounting apparatus

A technology for installing devices and components, applied in the direction of electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

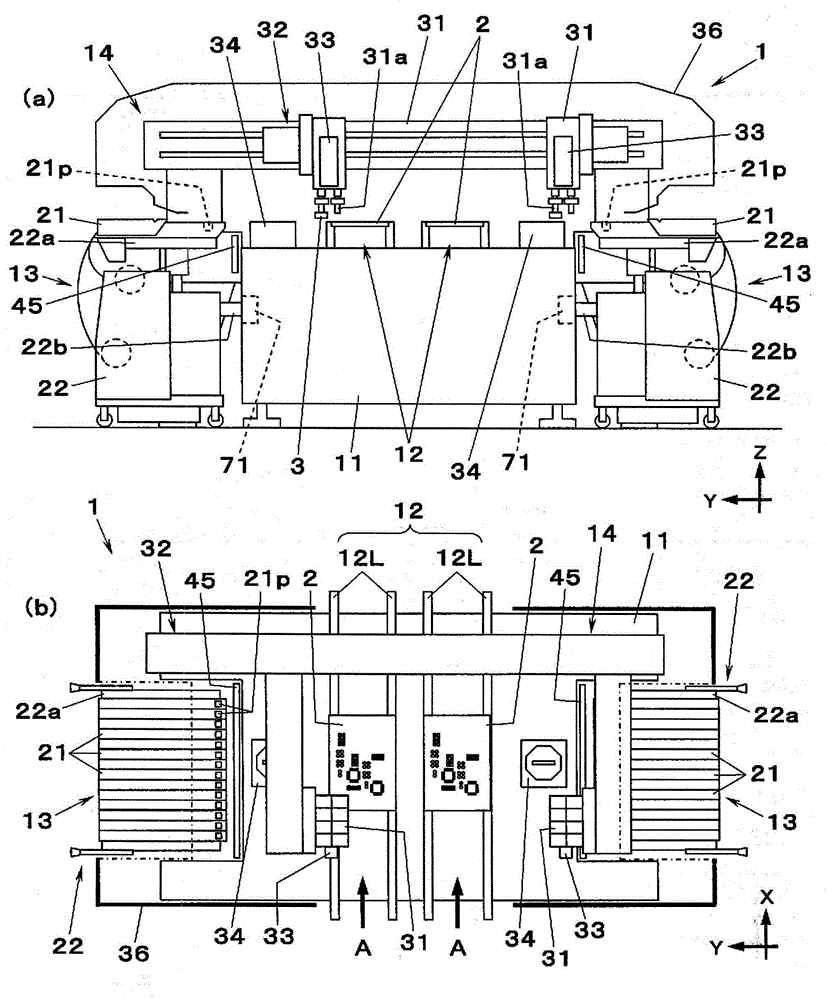

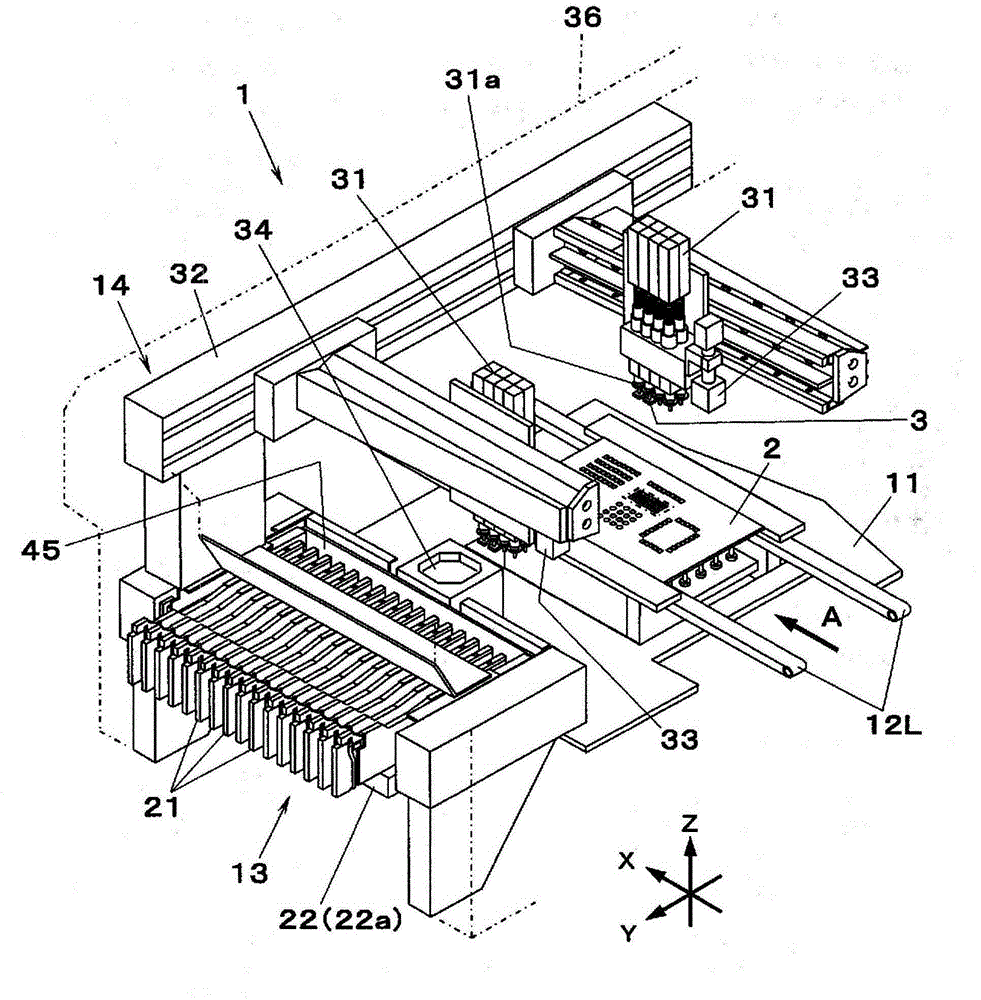

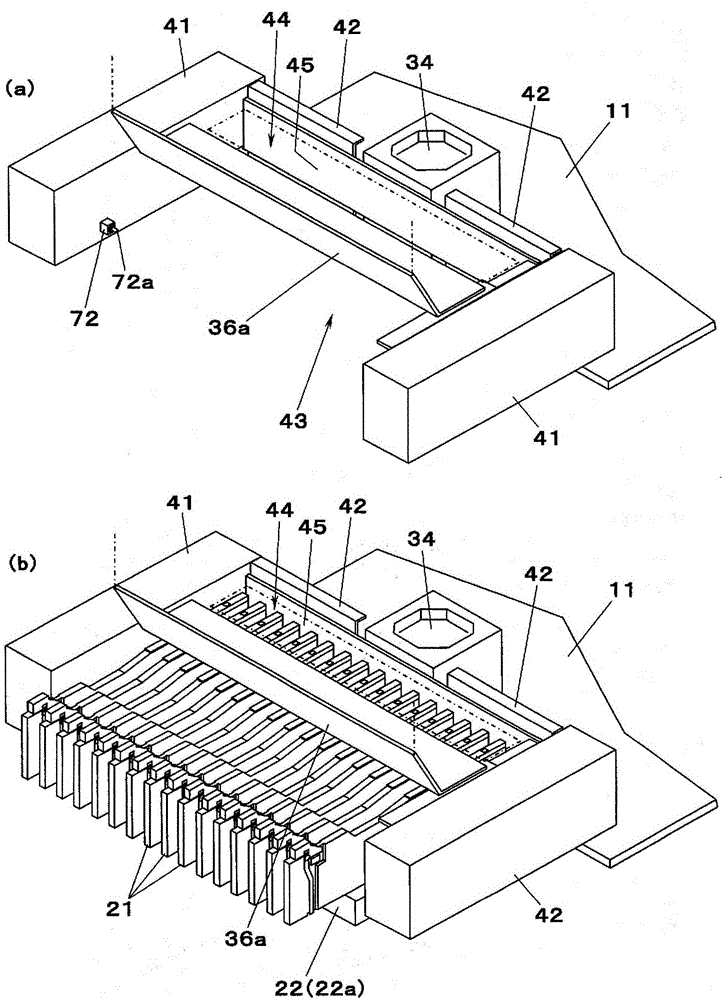

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 (a), (b) and figure 2 The shown component mounting apparatus 1 represents one embodiment of the present invention. The component mounting apparatus 1 includes a substrate transport unit 12 , a component supply unit 13 , and a component mounting unit 14 on a base 11 , and repeatedly performs an operation of mounting a component 3 on a substrate 2 . Here, for convenience of description, the conveying direction in which the substrate conveying unit 12 conveys the substrate 2 ( figure 1 (b) and figure 2 The arrow A) shown in , is the X-axis direction (the left-right direction as viewed from the operator), and the horizontal in-plane direction (the front-rear direction as viewed from the operator) perpendicular to the X-axis direction is the Y-axis direction. In addition, let the up-down direction be a Z-axis direction.

[0037] exist figure 1 (a), (b) and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com