A kind of tea automatic milling equipment

A Quhao and automatic technology, applied in the field of automatic Quhao equipment, can solve the problems of wasting manpower, difficult to achieve batch production of tea, automatic production, no automatic feeding and automatic discharging, etc., and achieve the effect of saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

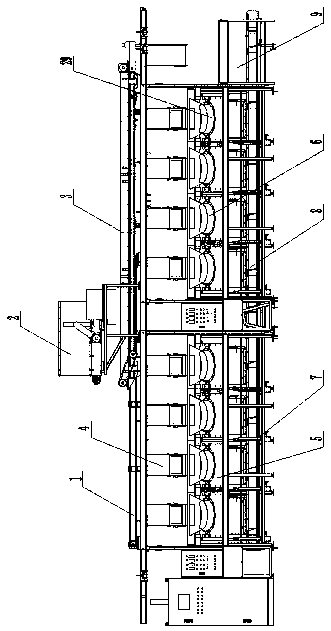

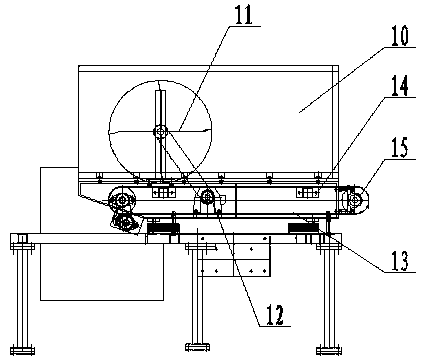

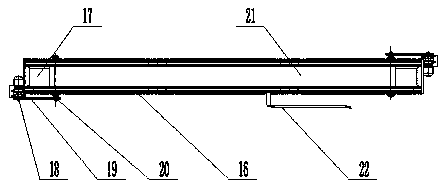

[0027] Examples. An automatic tea milling equipment, composed as Figure 1-Figure 8 As shown, the bracket 1 is provided with a distributing trolley 3, the distributing trolley 3 is provided with a discharging box 4, and the distributing box 4 is provided with a bending machine 5 and a bending machine 5 A frying plate mechanism 29 is arranged above the quhao machine pot 6; the quhao machine pot 6 is connected with an organic pot turning mechanism 7. A conveying device 8 is provided below the pot turning mechanism 7 and a collecting device 9 is provided above the right end of the conveying device 8. The distributing trolley 3 includes a car body 16. The two ends of the car body 16 are respectively provided with material outlets 17, and the car body 16 is also provided with a conveyor belt 21. The conveyor belt 21 is connected with a sprocket 20 through which the sprocket 20 passes The chain 19 is connected with the third motor 18; the vehicle body 16 is also connected with a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com