A kind of iron-based metal oxide catalyst and its preparation method and application

A catalyst and solid oxide technology, applied in the field of catalysis, can solve problems such as difficult control of co-precipitation process and washing process, time-consuming and labor-consuming, catalyst production failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

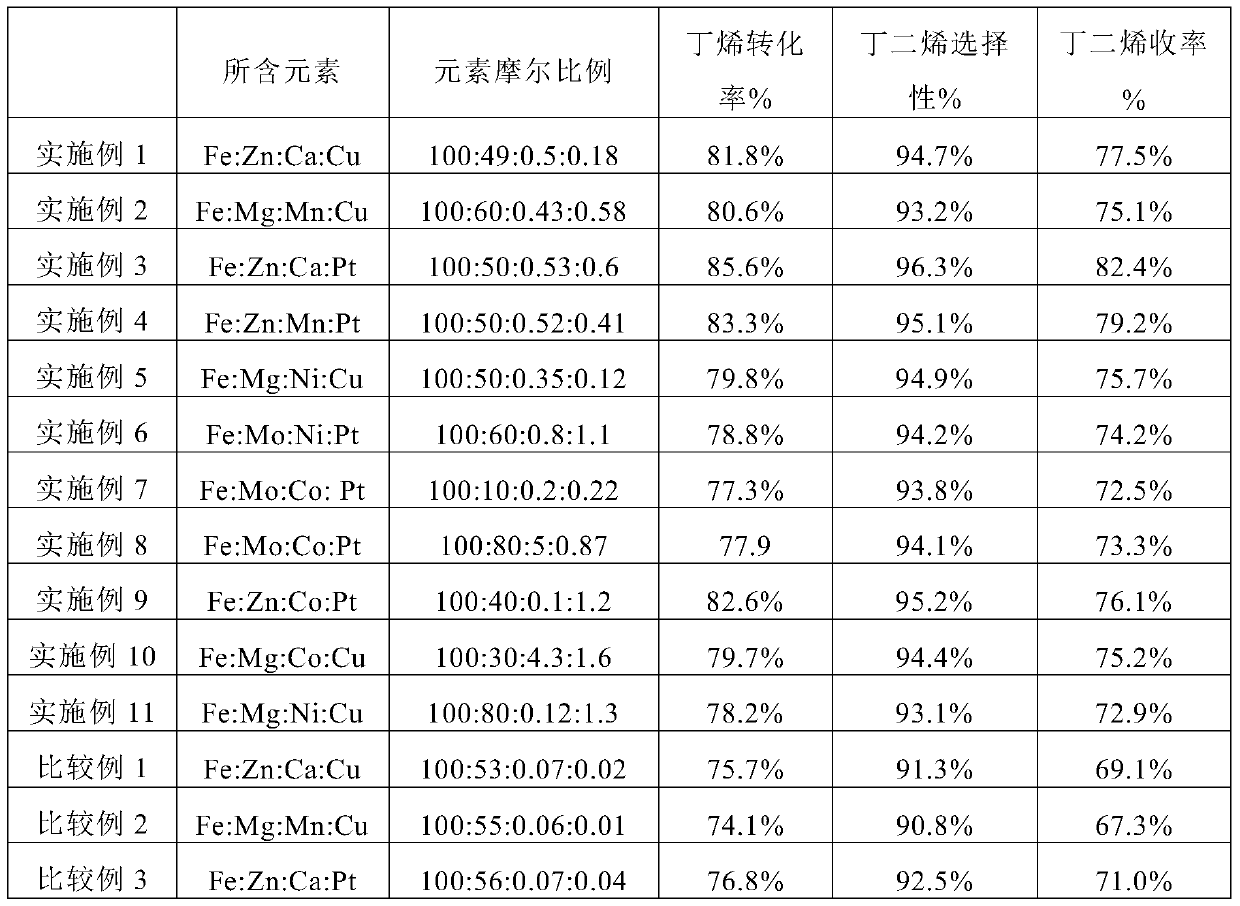

Examples

Embodiment 1

[0046] Weigh 1 mol iron nitrate, 0.5 mol zinc nitrate, 0.005 mol calcium nitrate, 0.002 mol copper nitrate, add them together into a high-speed pulverizer, mix and pulverize them at a speed of 25000r / min for 5 minutes, and the pulverized mixture Pour it out, dry it in an oven at 150°C to remove water for 3 hours, and obtain a mixed solid oxide, then add 100 grams of scallop powder, an appropriate amount of deionized water, and fully stir to obtain a mixed slurry with a solid content of 35% by mass . The resulting mixed slurry is input into the air-flow type spray drying granulator at a flow rate of 150 ml / min, the inlet temperature is 250° C., and the outlet temperature is 150° C. to obtain catalyst precursor microspheres, and then the catalyst precursor microspheres are transferred to In an infrared heater, it was dried at 120°C for 12 hours, then transferred to a muffle furnace, and calcined at 600°C for 10 hours to obtain a catalyst product. The catalyst particles have a p...

Embodiment 2

[0048] Weigh 1 mol iron nitrate, 0.6 mol magnesium nitrate, 0.005 mol manganese nitrate, 0.006 mol copper nitrate, add them together into a high-speed pulverizer, mix and pulverize them at a speed of 25000r / min for 5 minutes, and the pulverized mixture Pour it out, dry and remove water at 180°C for 2 hours to obtain a dry mixed solid oxide, add 100 grams of scallop powder and an appropriate amount of deionized water to it, and stir fully to obtain a mixed oxide with a solid content of 40% by mass. slurry. The resulting mixed slurry is input into the air-flow type spray drying granulator at a flow rate of 150 ml / min, the inlet temperature is 250° C., and the outlet temperature is 150° C. to obtain catalyst precursor microspheres, and then the catalyst precursor microspheres are transferred to In an infrared heater, it was dried at 120°C for 12 hours, then transferred to a muffle furnace, and calcined at 600°C for 10 hours to obtain a catalyst product. The catalyst particles ha...

Embodiment 3

[0050] Weigh 1 mol iron nitrate, 0.5 mol zinc nitrate, 0.005 mol calcium nitrate, 0.006 mol platinum nitrate, add them together into a high-speed pulverizer, mix and pulverize them at a speed of 25000r / min for 10 minutes, pour the pulverized mixture into drying at a temperature of 150° C. to remove water for 3 hours to obtain a dry mixed solid oxide, to which 100 grams of turnip powder and deionized water were added, and fully stirred to obtain a mixed slurry with a solid content of 40% by mass . The resulting mixed slurry is input into the air-flow type spray drying granulator at a flow rate of 150 ml / min, the inlet temperature is 250° C., and the outlet temperature is 150° C. to obtain catalyst precursor microspheres, and then the catalyst precursor microspheres are transferred to In an infrared heater, it was dried at 120°C for 12 hours, then transferred to a muffle furnace, and calcined at 600°C for 10 hours to obtain a catalyst product. The catalyst particles have a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com