Method for preparing propylene catalyst by propane dehydrogenation process

A technology for propane dehydrogenation and catalysts, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. To achieve the effect of enhancing the anti-coking ability, enhancing the effect and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 12.4 g of Dispal 11N7-80 (Boehmite) from Sol Company in 100 ml of deionized water, and stir at room temperature for 30 minutes to form an aluminum sol. Adding different amounts of SnCl 4 5H 2 O modified aluminum sol, continued to stir at room temperature for 30 minutes, placed the obtained sol in an oven at 70°C to dry overnight, then pulverized the obtained sample, sieved, and calcined at 700°C for 3 hours to obtain a modified alumina carrier.

[0018] The obtained tin-containing alumina carrier is loaded with a platinum component by impregnation technology, that is, the alumina carrier modified with different tin components is impregnated with an aqueous solution of a required amount of chloroplatinic acid for 24 hours at room temperature, and then 60 ℃ drying, calcination at 530 ℃ for 3 hours in air flow, followed by water vapor treatment at 530 ℃ for 4 hours, and finally drying air at 530 ℃ for 1 hour.

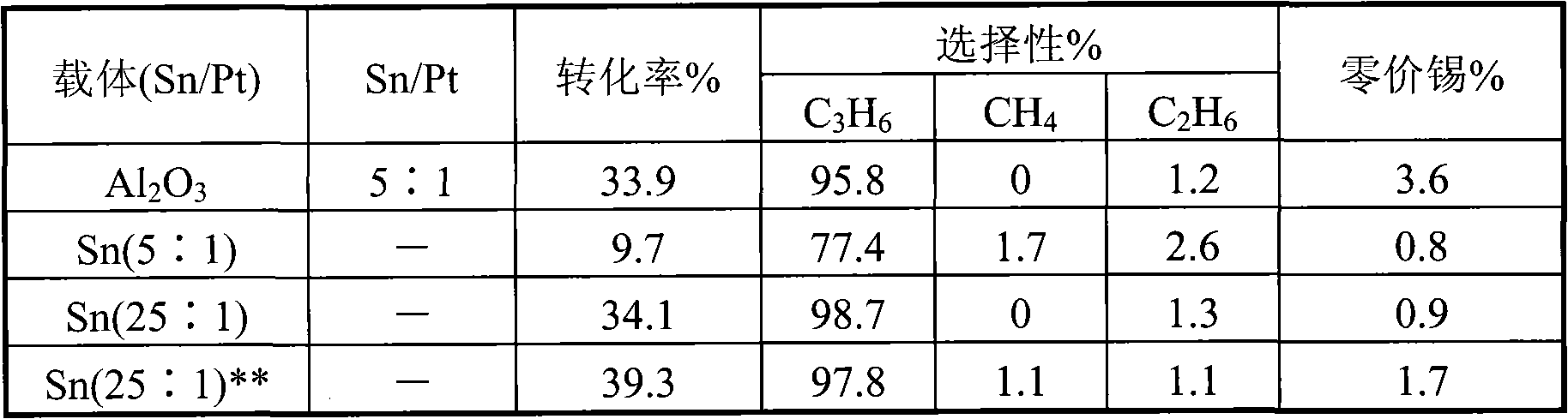

[0019] The sample was reductively activated with hy...

Embodiment 2

[0025] Dissolve 12.4 g of Dispal 11N7-80 (Boehmite) from Sol Company in 100 ml of deionized water, and stir at room temperature for 30 minutes to form an aluminum sol. Adding different amounts of SnCl 4 5H 2 O modified aluminum sol, continued to stir at room temperature for 30 minutes, placed the obtained sol in an oven at 70°C to dry overnight, then pulverized the obtained sample, sieved, and calcined at 650°C for 3 hours to obtain a modified alumina carrier.

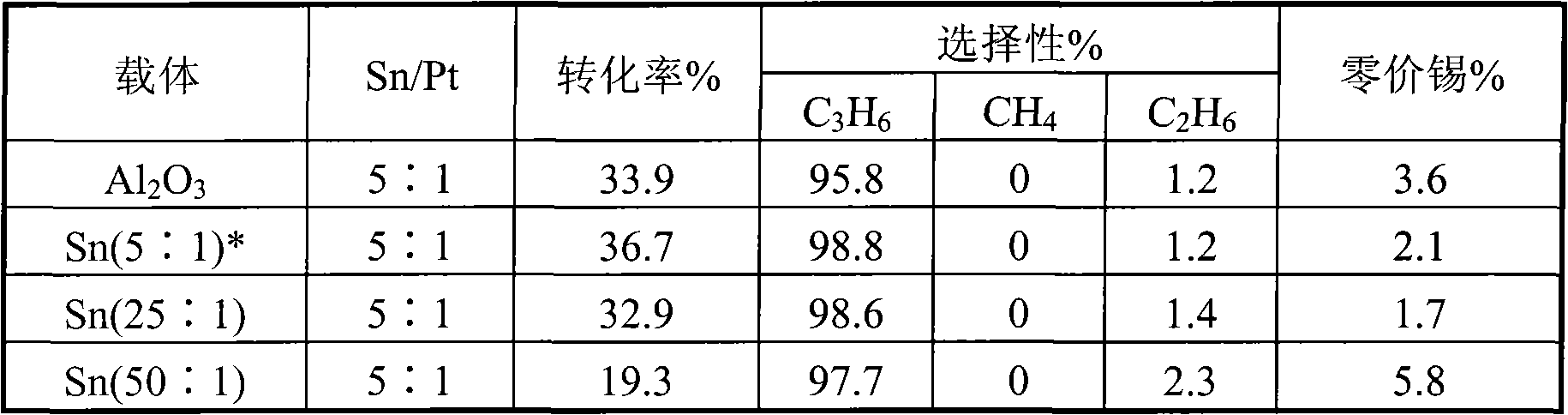

[0026] The obtained tin-containing alumina carrier is first loaded with tin components by impregnation method, that is, the alumina carrier modified by different amounts of tin components is impregnated with SnCl 4 The aqueous solution was dried for 24 hours, then dried at 60°C, calcined at 530°C in air for 3 hours, then treated with water vapor at 530°C for 4 hours, and finally treated with dry air at 530°C for 1 hour. Then, the impregnation method was used to load the platinum component, that is, the sample loaded ...

Embodiment 3

[0032] Mix 30% sodium silicate aqueous solution with 27% sulfuric acid solution to prepare silica sol. Add the required amount of SnCl with stirring 4 5H 2 O modified aluminum sol, continued to stir at room temperature for 30 minutes, placed the obtained sol in an oven at 70°C to dry overnight, then pulverized the obtained sample, sieved, and calcined at 750°C for 3 hours to obtain a modified silica carrier.

[0033] The obtained tin-containing silicon oxide carrier is loaded with platinum and other metal components by the co-impregnation method, that is, the required amount of H for impregnating the above carrier 2 PtCl 6 Aqueous solution of soluble salts of other metal additives for 24 hours, then dried at 60°C, calcined at 530°C in air flow for 3 hours, then treated with water vapor at 530°C for 4 hours, and finally treated with dry air at 530°C for 1 hour , to obtain the catalyst precursor.

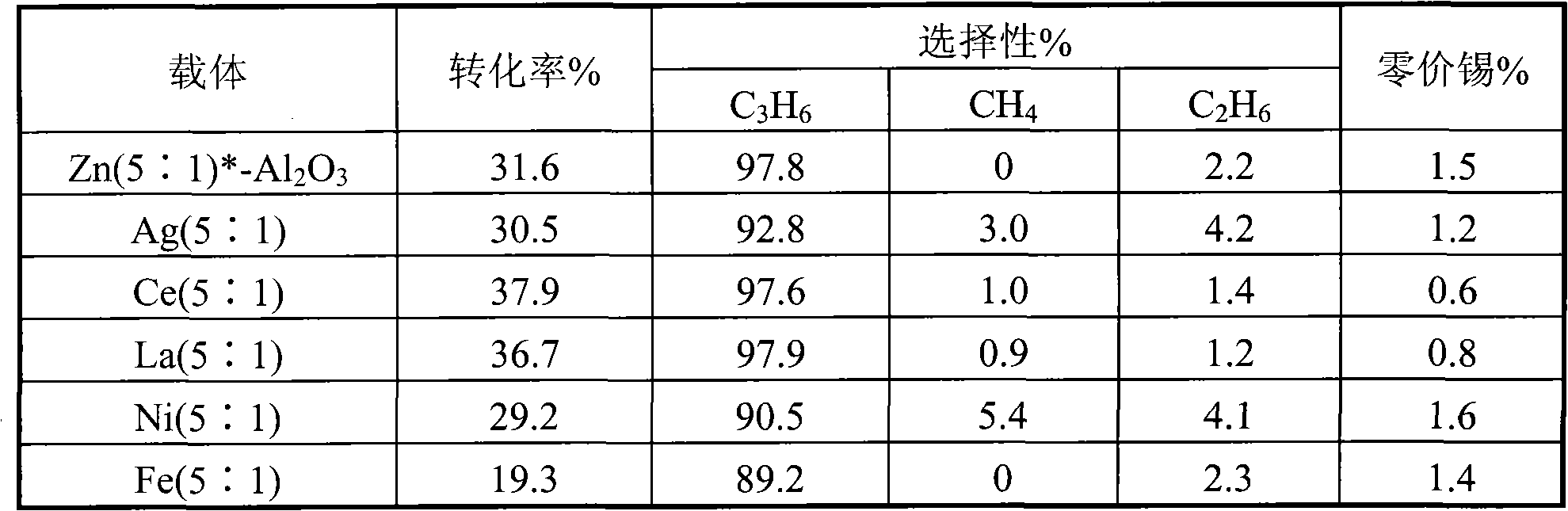

[0034]The sample was reductively activated with hydrogen at 550°C for 60 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com