A screening mechanism for jujube processing

A technology for screening and candied dates, which is applied in the fields of grading, solid separation, chemical instruments and methods, etc., can solve the problems of stuck scribing holes, affecting the normal operation of scribing equipment, and being unsuitable for the use of scribing equipment. The effect of sub-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

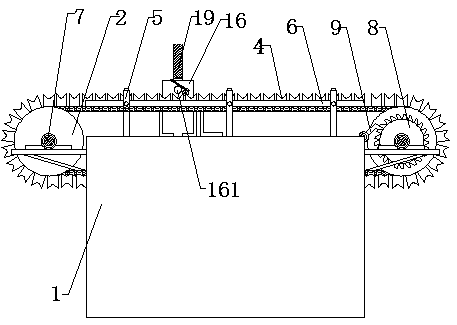

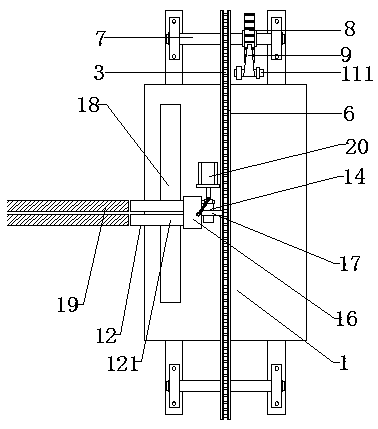

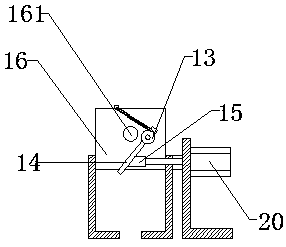

[0022] Refer to attached Figure 1-5 A screening mechanism for jujube processing shown includes a transport platform 1, a support 5 is also provided on the side of the transport platform 1, a baffle plate 6 is arranged on the support 5, and both ends of the transport platform 1 are provided with Concentric shafts 7, two transmission chains 3 parallel to each other are connected between the two concentric shafts 7, and a plurality of equal-sized and side-by-side connection grooves 4 are formed between the two transmission chains 3. On the transmission chains 3 A number of V-shaped teeth are set, and the connecting slots are formed between the two V-shaped teeth at the corresponding positions on the two transmission c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com