Data-based positioning method for printing rubber roller cutting and cutting and scribing device

A technology for printing a rubber roller and a scribing device, applied in the field of printing, can solve problems such as reducing production efficiency, and achieve the effects of compact design structure, strong production practicability, and improved position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

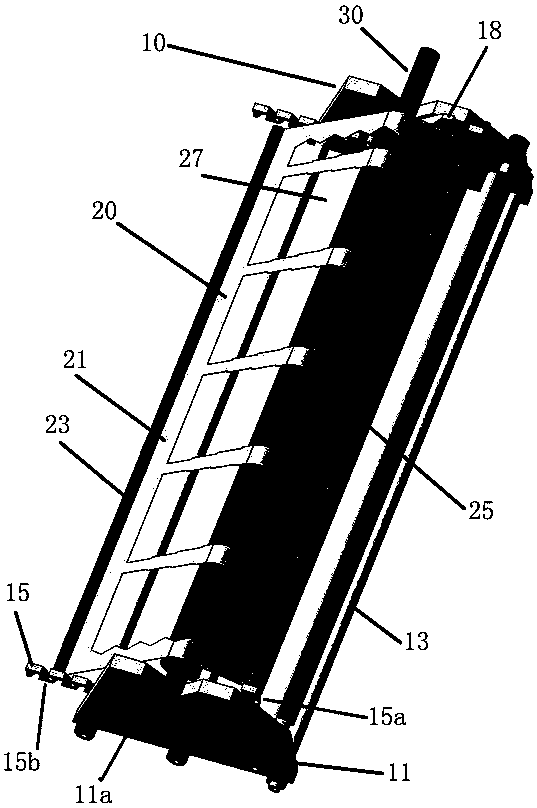

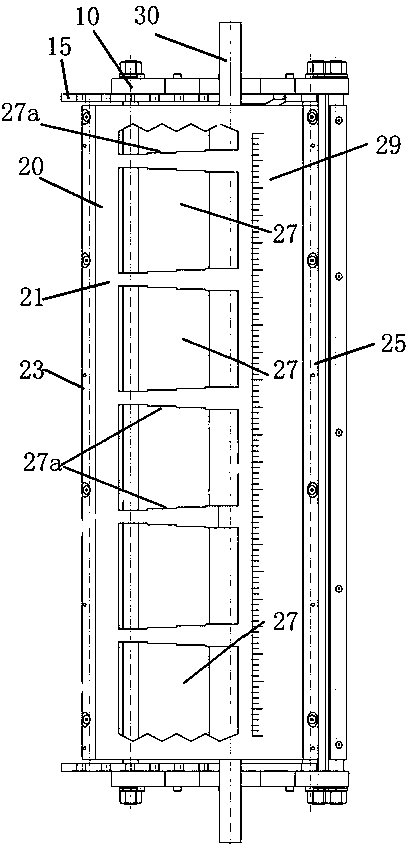

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0028] A data-based positioning method for printing rubber roller cutting, the method comprising the following steps:

[0029] Step 1. Coincide the midline of the printing paper in the axial direction with the midline of the ink form roller, the ink spreader and the ink transfer roller in the axial direction to determine the working area, and mark the work area, wherein the ink form roller, the ink spreader to The working part of the ink transfer roller increases gradually;

[0030] Step 2, according to the axial length of the image and text area on the printing plate, determine the reserved area and the cutting area in the working part on the ink form roller, the ink equalizing roller and the ink transfer roller, and mark the line;

[0031] Step 3, cutting and removing the glue layer outside the working part of the ink form roller, ink equalizing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com