A Method of Using Diffraction Patterns to Calibrate Pinhole Positions in Spatial Filters

A technology of spatial filter and diffraction pattern, applied in instruments, optical components, optics, etc., can solve the problems such as the inability to accurately determine the relative position of the spatial filter and the distortion of the outgoing laser spot, and achieve simple, efficient, practical, accurate calibration, and adjustment. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

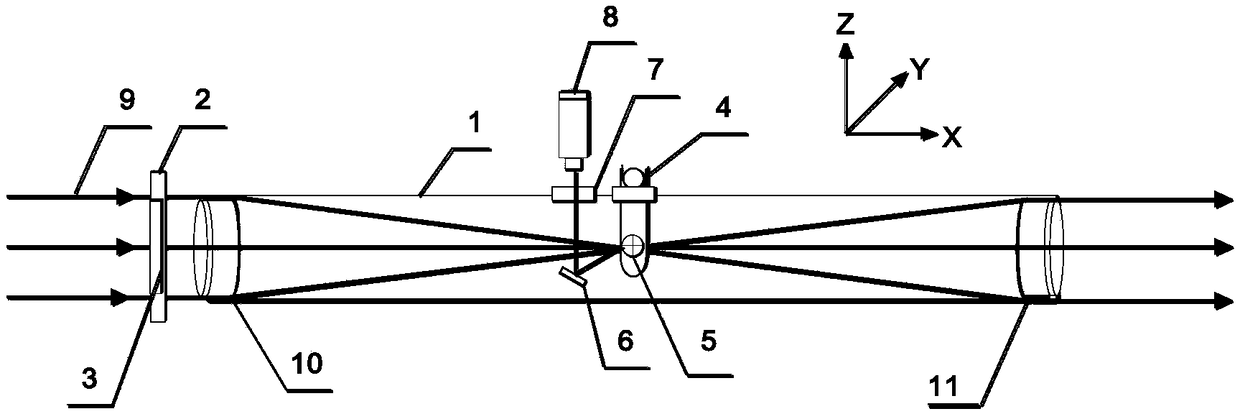

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0027] In order to solve the current problem that the relative position between the small hole in the spatial filter and the laser focus cannot be accurately determined, resulting in a certain deviation when the laser passes through the hole, which eventually leads to the distortion of the exit spot, the present invention proposes a method of using a diffraction pattern to determine A method to mark the location of pinholes in a spatial filter.

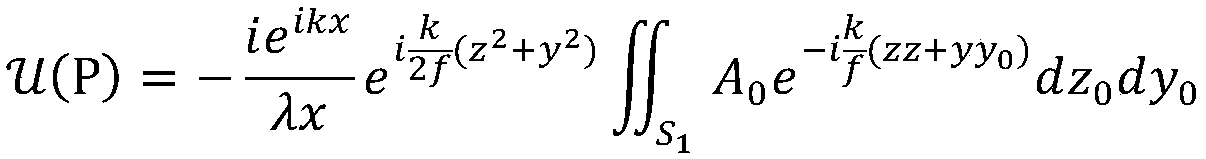

[0028] A method for calibrating the position of a small hole in a spatial filter using a diffraction pattern, the specific steps are as follows:

[0029] Step 1, take the cross-section of the small hole 5 in the spatial filter 1 as the YZ plane, fix the calibration diaphragm bracket 2 on the front end of the spatial filter 1 along the X-axis direction, so that the front lens 10 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com