Box culvert assembling and aligning machine

A technology of leveling machine and box culvert, applied in the direction of building, road bottom, etc., can solve the problems of difficult movement of single unit, heavy box culvert, etc., and achieve the effect of flexible operation, stable structure and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

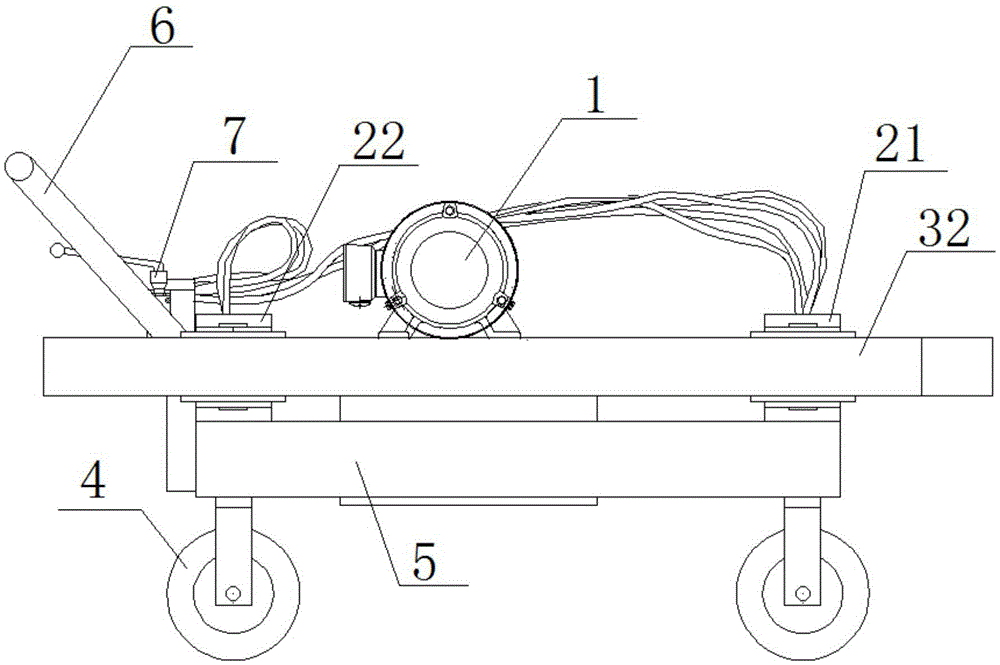

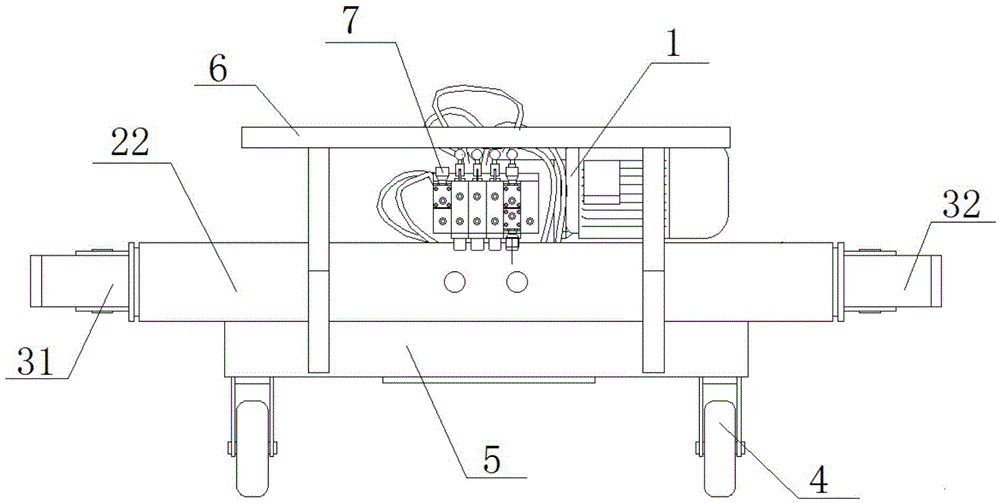

[0017] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0018] refer to figure 1 , figure 2 , a kind of box culvert assembly adjustment machine provided by the present invention comprises: traveling vehicle frame (chassis) 5, alignment steel girder 31,32, hydraulic cylinder 21,22, hydraulic station 1, multidirectional valve 7, oil pipeline, Walking car armrest 6, walking wheel 4 etc.

[0019] The traveling vehicle frame 5 is arranged horizontally and is the main bracket for supporting the host equipment; the traveling wheel 4 is installed under the traveling vehicle frame 5 to facilitate the movement of the device; the No. 1 hydraulic cylinder 21 and the No. 2 hydraulic cylinder 22 are installed on the traveling vehicle in parallel On the frame 5, No. 1 alignment steel beam 31 and No. 2 alignment steel beam 32 are installed in parallel on the outside of No. 1 hydraulic cylinder 21 and No. 2 hydraulic cylinder 22....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com