Flexible package for creams

A technology of flexible packaging and emulsion, applied in the field of flexible packaging, can solve the problems of sticking to the tube wall of flexible packaging, time-consuming, laborious, and troublesome extrusion, and achieve the effects of resource saving, convenient use, and high extrusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

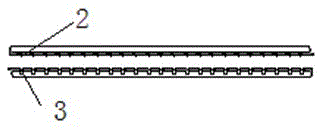

[0019] Refer to attached figure 1 and figure 2 , this embodiment includes a flexible packaging body 1, a plurality of transverse grooves 3 are arranged on the inner side of the flexible packaging body 1, and the transverse grooves 3 are arranged continuously from the tail to the head of the flexible packaging body 1, the length of the transverse groove 2 and the transverse protrusion The lengths of the openings 2 are smaller than the width of the flexible packaging body 1, the length of the transverse groove 3 is consistent with the width of the flexible packaging body 1, the gap between two adjacent transverse grooves 3 is 0 mm, and the other side of the flexible packaging body 1 is provided with The transverse protrusion 2 adapted to the transverse groove 3, the material of the transverse groove 3 and the transverse protrusion 2 is plastic.

[0020] In this embodiment, the ratio of the width of the transverse groove 3 to the length of the flexible packaging body 1 is 1:12,...

Embodiment 2

[0023] Refer to attached figure 1 and figure 2 , this embodiment includes a flexible packaging body 1, a plurality of transverse grooves 3 are arranged on the inner side of the flexible packaging body 1, and the transverse grooves 3 are arranged continuously from the tail to the head of the flexible packaging body 1, the length of the transverse groove 2 and the transverse protrusion The lengths of the protrusions 2 are smaller than the width of the flexible packaging body 1, the gap between two adjacent transverse grooves 3 is 0.05mm, and the other side of the flexible packaging body 1 is provided with a transverse protrusion 2 that matches the transverse groove 3, The material of the transverse groove 3 and the transverse protrusion 2 is plastic.

[0024] In this embodiment, the ratio of the width of the transverse groove 3 to the length of the flexible packaging body 1 is 1:18, and the ratio of the depth of the transverse groove 3 to the height of the flexible packaging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com