Method for alleviating vibration during dehydration of impeller washing machine

A pulsator washing machine, washing machine technology, applied to the control device of the washing machine, washing machine with container, application, etc., can solve the problems of imbalance, washing machine movement, washing machine can not be judged, etc., to achieve the effect of preventing damage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

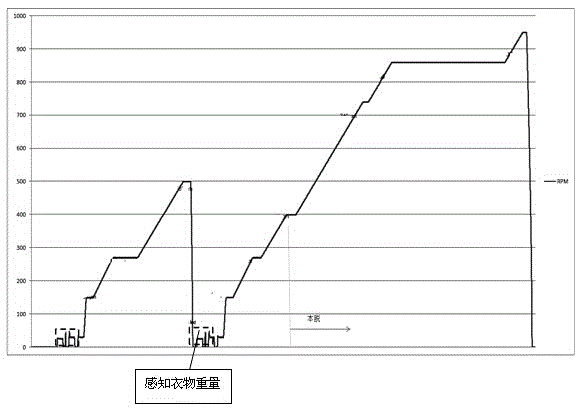

[0014] see figure 1 As shown, a method for alleviating vibration when dehydrating a top-wheel washing machine is characterized in that:

[0015] When the washing machine is dehydrating, the dehydration step is divided into the first stage of dehydration and the second stage of dehydration;

[0016] Among them, the first stage of dehydration ends, before the second stage of dehydration starts, the motor speed of the washing tub is reduced to below 100rpm, and then the weight sensor senses the weight of the clothes in the washing machine and then restarts to perform the second stage of dehydration. Re-confirm the dehydration unbalance Table value to avoid the washing machine not being able to sense the unbalanced dehydration in some cases due to the large difference between the state of the clothes after a period of dehydration and the pre-dehydration when using the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com