Semi-automatic clutch device

A clutch device, semi-automatic technology, applied in the direction of sliding coupling, mechanical equipment, coupling, etc., can solve the problem that the host equipment is not applicable, does not have overload protection function, and the coupling cannot automatically disconnect the main and driven shafts and other problems, to achieve the effect of compact structure, safe and reliable operation, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

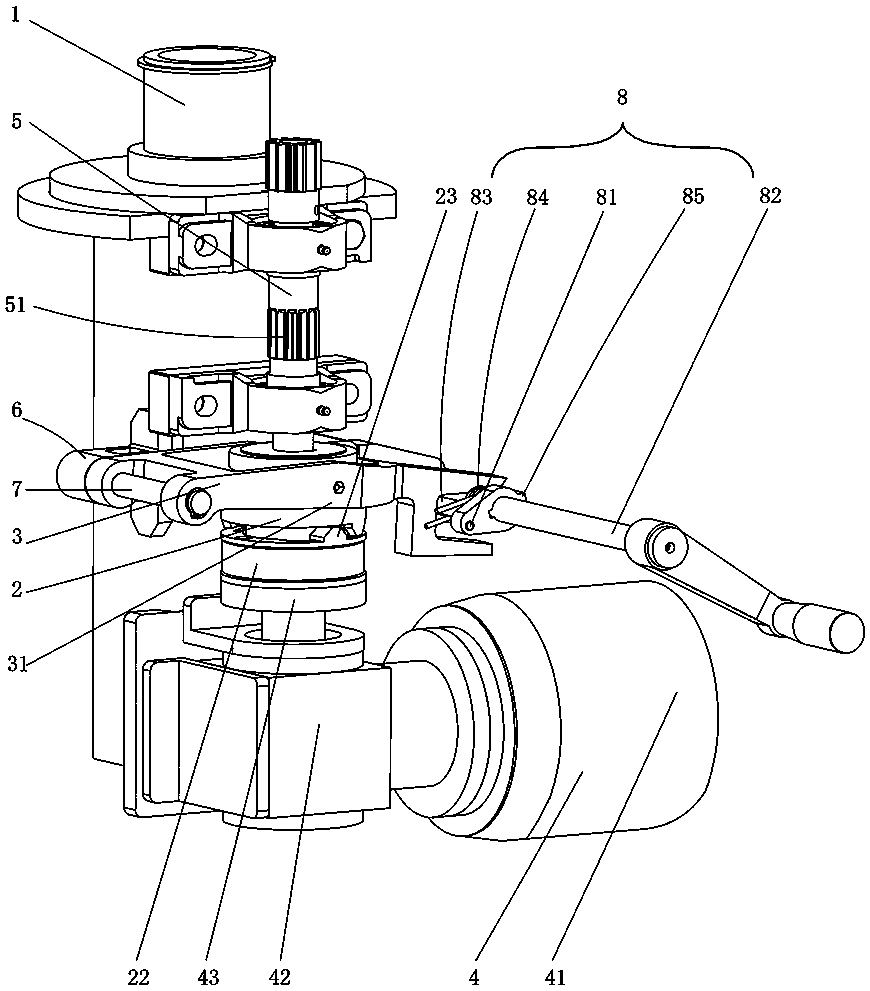

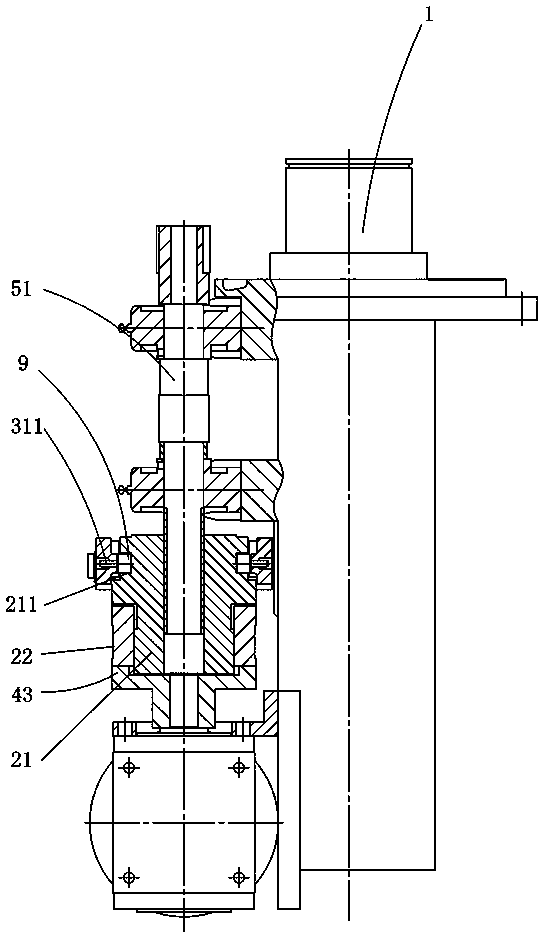

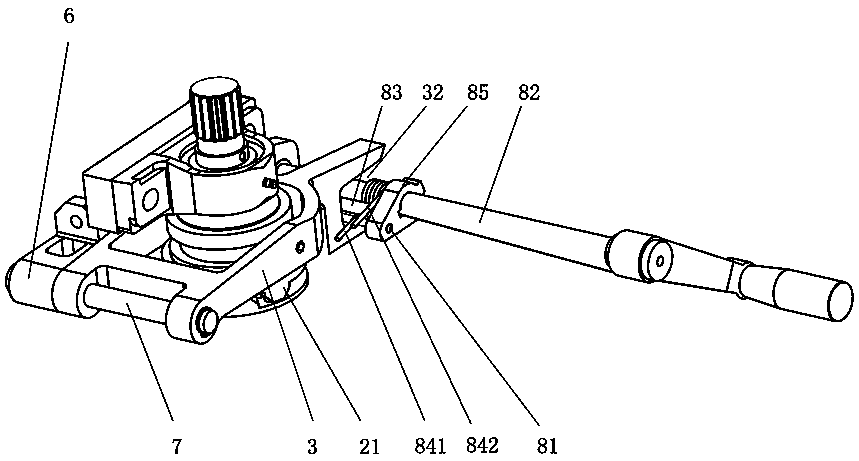

[0019] Figure 1 to Figure 3 An embodiment of the semi-automatic clutch device of the present invention is shown, the semi-automatic clutch device includes a main shaft seat 1, a clutch 2 and a connecting rod 3, the clutch 2 includes a clutch upper plate 21 and a clutch lower plate 22 meshing with each other, and the clutch lower plate 22 It is connected with the power part 4, the clutch upper plate 21 is connected with the driven part 5, the bearing seat 6 is fixed on the main shaft seat 1, the head end of the connecting rod 3 is hinged with the bearing seat 6 and the middle part is fixedly connected with the clutch upper plate 21, and the connecting rod 3 The tail end is provided with a locking assembly 8, which locks the upper clutch plate 21 and the lower clutch plate 22 by pressing the connecting rod 3. When the driven part 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com