Multi-way pipe connector

A multi-way pipe and pipe joint technology, applied in the field of multi-way pipe joints, can solve the problems of single one-way, two-way or even three-way, narrow use range, and limited use range, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

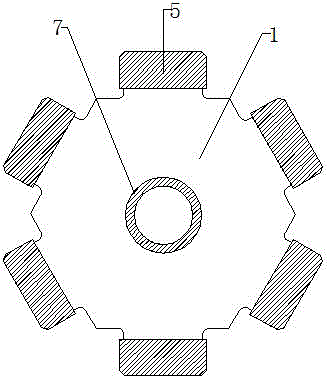

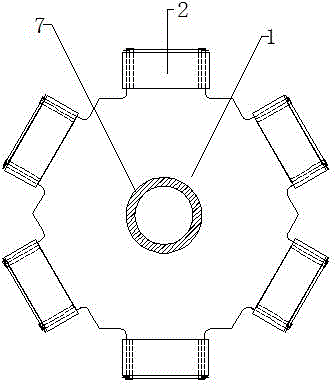

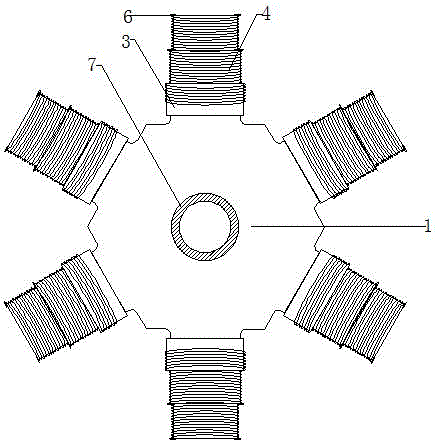

[0019] Embodiment: refer to attached Figure 1-4 The shown multi-way pipe joint includes a regular polygonal fluid converter 1, the fluid converter 1 is a regular hexagonal structure, the regular polygonal structure can satisfy the multi-way pipe joint on the one hand, and on the other hand can make each pipe The orientation of the joints is different, and they all scatter around to prevent the connecting pipes from being entangled when there are too many connecting pipes. The liquid can be evenly distributed in the fluid converter 1. The front and back of the fluid converter 1 are equipped with connecting rings. 7. The connecting ring 7 can be used for the fixed installation of the fluid converter 1. On the side of each side of the fluid converter 1, a pipe joint 2 is uniformly connected, and the fluid converter 1 distributes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com