LED surface light-emitting tri-proof lamp

A three-proof light, surface-emitting technology, applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problem of places where people or vehicles cannot be used with large circulation, insufficient moisture and gray layer protection level, and uneven performance. and other problems, to achieve the effect of prolonging the service life, better dustproof effect and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Side-emitting mode LED surface-emitting tri-proof lamp

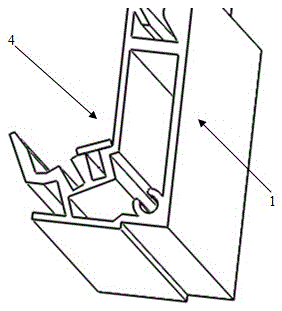

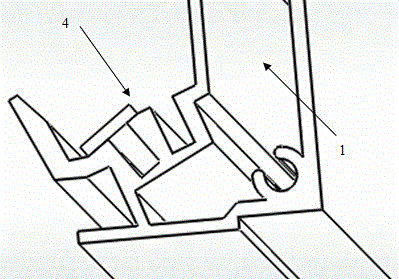

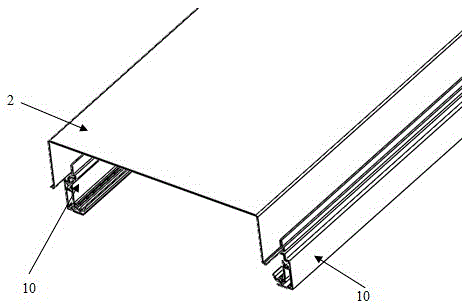

[0040] The tri-proof lamp includes a lamp body 1, an aluminum substrate 4 placed in the lamp body, a base plate 2 and a cover 5 respectively placed on the upper and lower sides of the lamp body, and end caps 7 are provided at both ends of the lamp body. Lamp beads are welded, and the lamp body is composed of two mutually symmetrical L-shaped sub-housings 10. The bottom plate is placed between the two sub-housings, and the two sides are respectively inserted into the corresponding (bottom plate) installation grooves 11 inside the two sub-housings. Inside, the face cover is placed between the two sub-housings, and its two sides are respectively inserted into corresponding (panel) installation grooves 12 inside the two sub-housings.

[0041] There are 2 aluminum substrates, which are respectively placed at the angle between the two sides of the L-shaped sub-housing. The angle between the two aluminum substrates is 42...

Embodiment 2

[0048] Direct lighting mode LED surface emitting tri-proof light

[0049] The tri-proof lamp includes a lamp body 1, an aluminum substrate 4 placed in the lamp body, a base plate 2 and a cover 5 respectively placed on the upper and lower sides of the lamp body, and end caps 7 are provided at both ends of the lamp body. The lamp beads are welded, and the lamp body is composed of two mutually symmetrical L-shaped sub-housings 10. The cover is placed between the two sub-housings, and its two sides are respectively inserted into corresponding installation grooves 12 inside the two sub-housings.

[0050] The aluminum substrate is placed on the top of the bottom plate in the lamp body, and the cover is an explosion-proof tempered glass cover. The aluminum substrate is fixed on the top of the bottom plate in the lamp body by rivets.

[0051]The upper part of the bottom plate is provided with a U-shaped mounting bracket, and the two ends of the mounting bracket are respectively inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com