Tyre splashing test device

A test device and water splashing technology, which is applied in the field of aircraft water splashing test, can solve the problems of wind direction and wind speed affecting test results, affecting vehicle visibility, difficult tire splashing measurement and research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

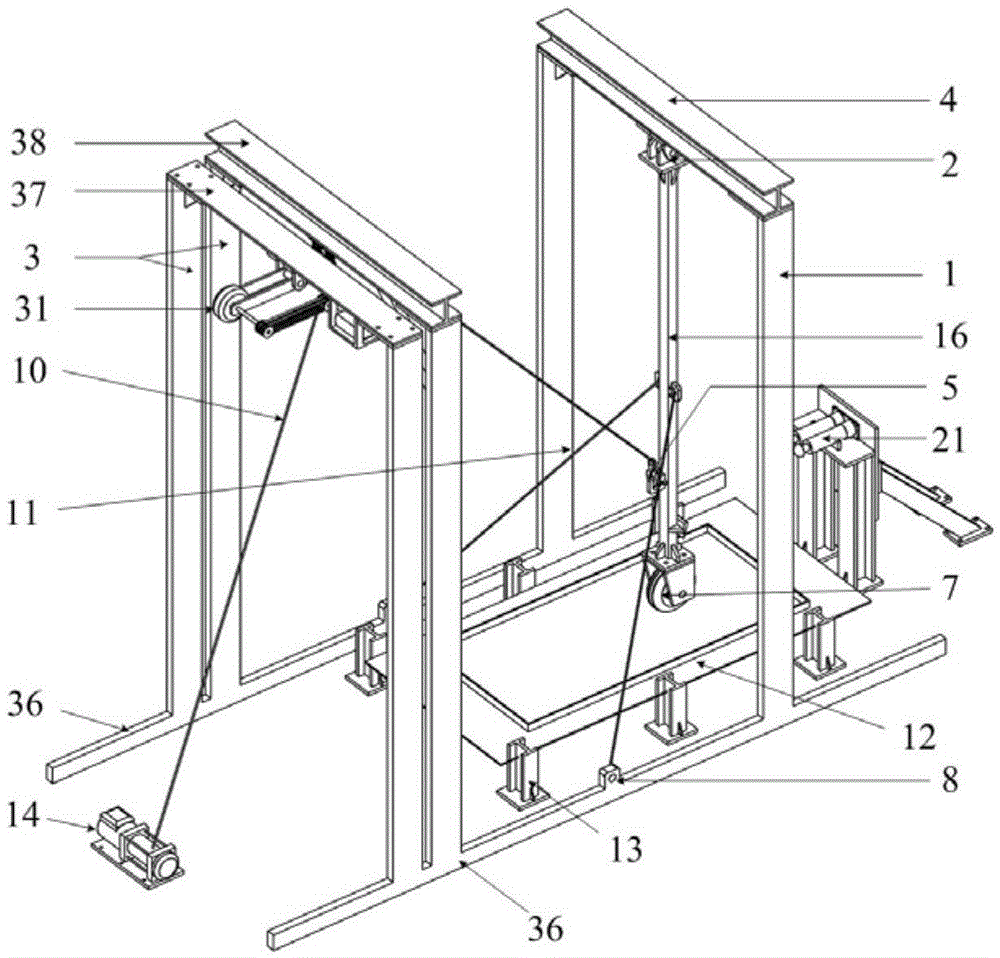

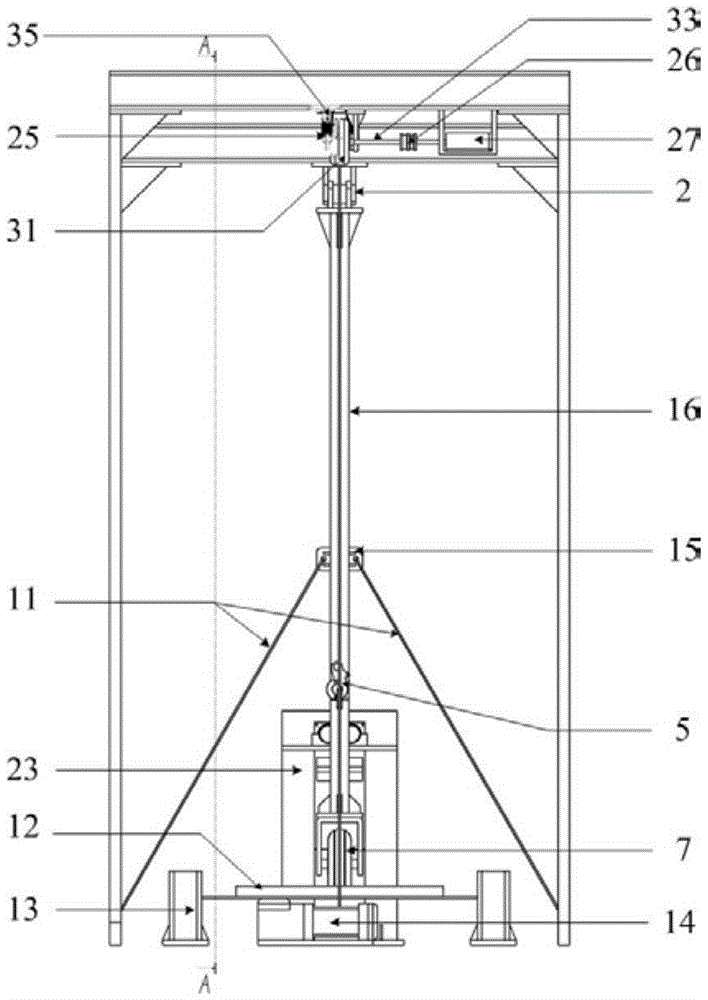

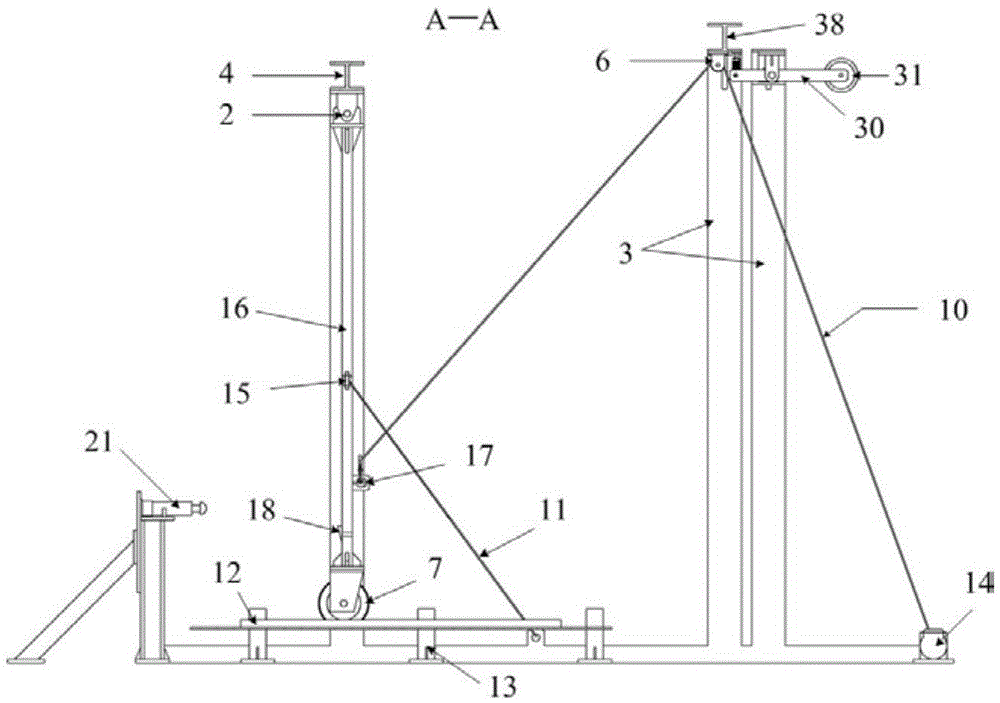

[0037] This embodiment is a tire splash test device.

[0038] The tire splash test device includes a test bench, a swing bar rotation mechanism, a pre-rotation mechanism, a buffer mechanism, a water pool and a lifting mechanism. in:

[0039] The test bench includes two gantry frames, namely the low gantry frame 1 for installing the swing bar rotation mechanism and the high gantry frame 3 for installing the pre-rotation mechanism. The low gantry and the high gantry are arranged in front and back, and are fixed on the same pair of ground fixing rods 36 . The swing rod rotating mechanism is hoisted on the middle part of the lower surface of the low gantry beam 4, and can swing back and forth. The high gantry 3 includes a first beam 37 and a second beam 38; the first beam and the second beam are parallel to each other, and the second beam is close to the low gantry. The two spring hooks 35 of the pre-rotation mechanism are fixed on the middle part of the lower surface of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com