Method for obtaining theoretical strain in strength finite element analysis

A theoretical strain and finite element technology, applied in special data processing applications, electrical digital data processing, instruments, etc., to achieve the effects of simplified acquisition steps, simple and clear principles, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings, please refer to Figure 1 to Figure 2 .

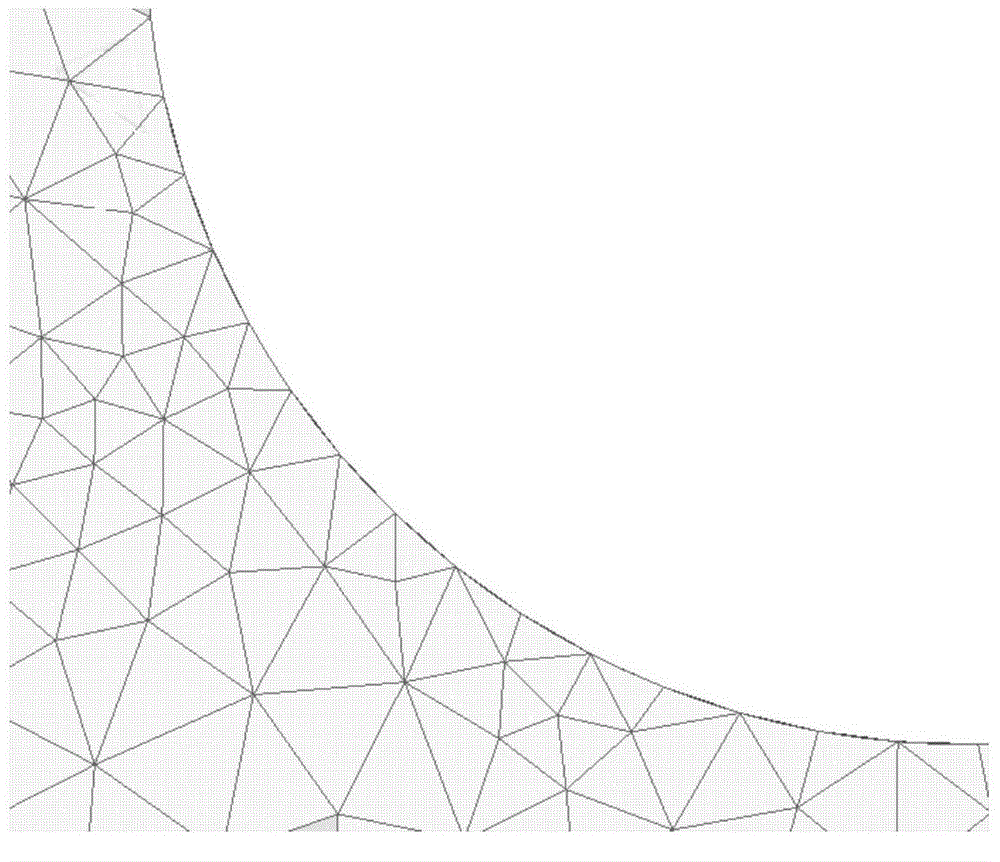

[0014] Such as figure 1 Shown is the partial mesh diagram of the finite element model of the test piece;

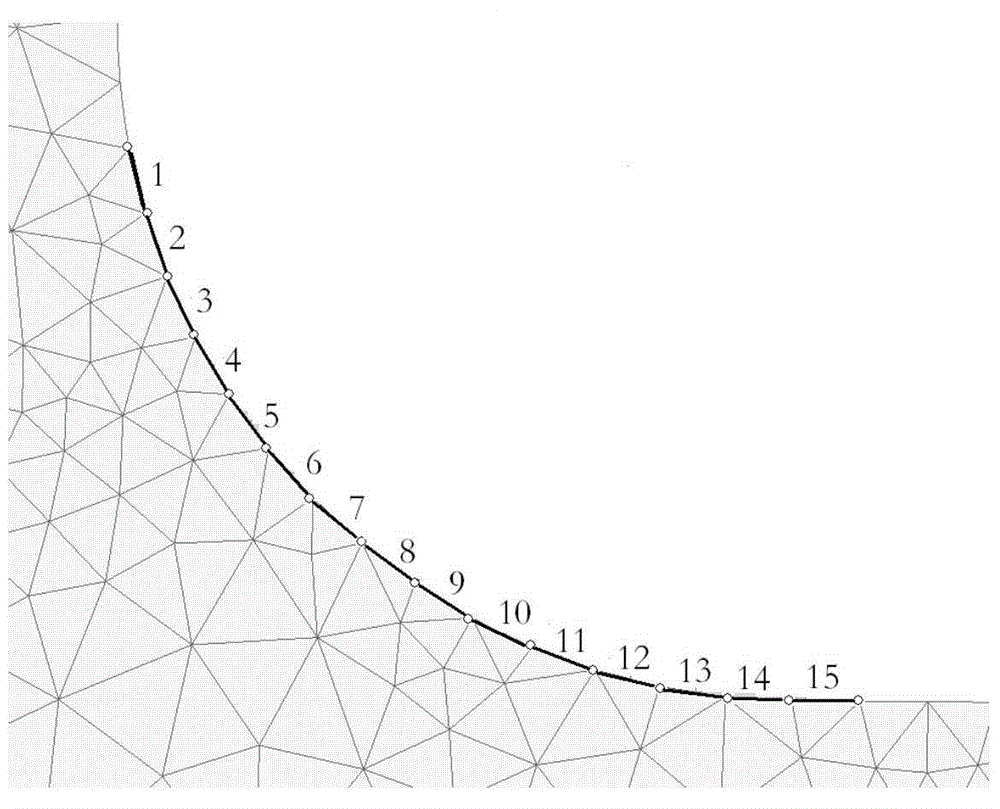

[0015] Such as figure 2 As shown, in the finite element model of the test piece, an additional rod element is established according to a given arbitrary position and direction, numbered from 1 to 15;

[0016] A method for obtaining theoretical strain in strength finite element analysis, including the following steps:

[0017] Step 1: According to the finite element principle and the principle of strain sensor measurement, an additional rod element is established in the finite element model of the test piece according to the given arbitrary position and direction;

[0018] Step 2: Define the stiffness characteristics of the rod element to be infinitely small relative to the local stiffness characteristics of the structure;

[0019] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com