Energy-saving mushroom fruiting workshop

A technology for fruiting workshops and gaps, applied in energy-saving measures, greenhouse cultivation, agricultural machinery and equipment, etc., can solve the problems of waste of water resources, high cost, difficulty in achieving continuous production throughout the year, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

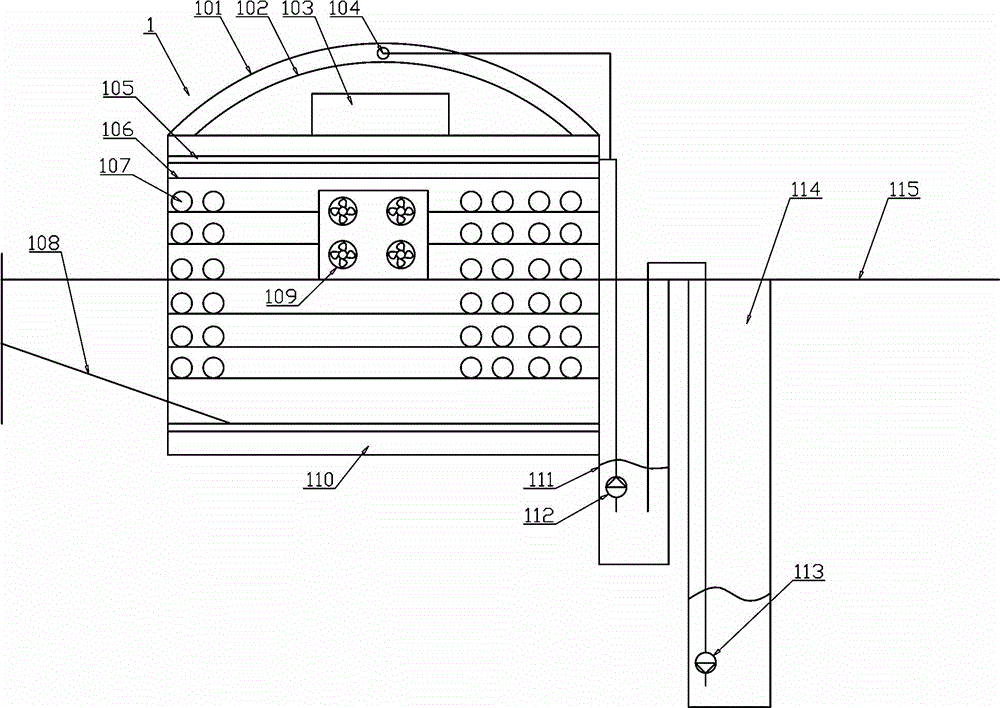

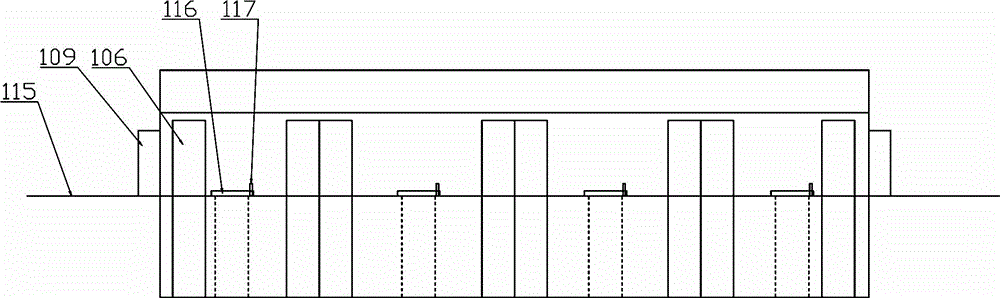

[0020] Such as figure 1 , 2 Among them, an energy-saving mushroom production workshop, the top of the mushroom production workshop 1 is provided with a transparent roof, and the shelf 106 for placing the mushroom tube is arranged along the width direction of the mushroom production workshop 1, and gaps are provided between the shelf 106, and the mushroom production workshop 1. A plurality of doors are provided on at least one side along the length direction, and the positions of the doors correspond to the gaps between the shelves 106;

[0021] A water curtain device 116 is provided on the top of the door, and a humidification spray pipe 105 is provided in the fruiting workshop 1. The water curtain device 116 and the humidification spray pipe 105 communicate with the circulation well 111 through a pipeline and a circulation pump 112;

[0022] A circulation channel 110 is provided in the fruiting workshop 1, and the circulation channel 110 communicates with the circulation wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com