Fire extinguishing agent and preparation method thereof

A technology of fire extinguishing agent and bean cake, which is applied in fire protection equipment and other directions, can solve the problems of complex preparation process and high production cost, and achieve the effects of good fluidity, easy operation and strong film forming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

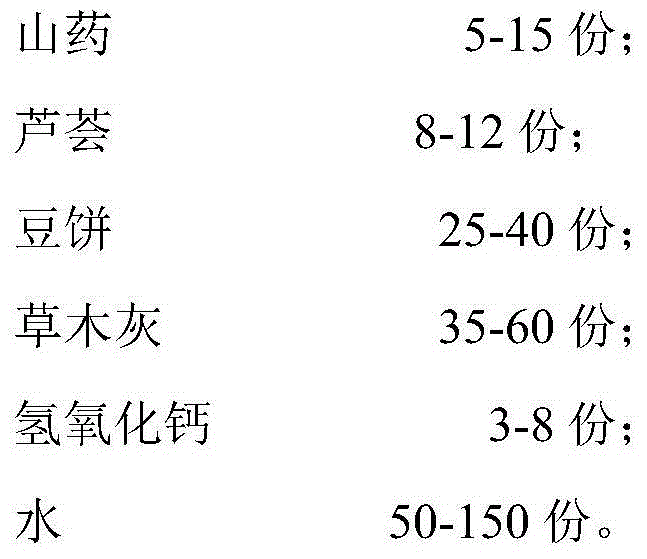

Method used

Image

Examples

Embodiment 1

[0032] Each component was weighed according to the following mass: yam 6kg, aloe 8kg, bean cake 30kg, plant ash 35kg, calcium hydroxide 4kg, water 120kg. Mix yam, aloe, bean cake, and plant ash evenly, add 50kg of water, react for 5 days, and then add the remaining components to it to obtain the product.

[0033] The product prepared in Example 1 was tested, and the test results are shown in Table 2.

[0034] The test result of table 2 embodiment 1

[0035]

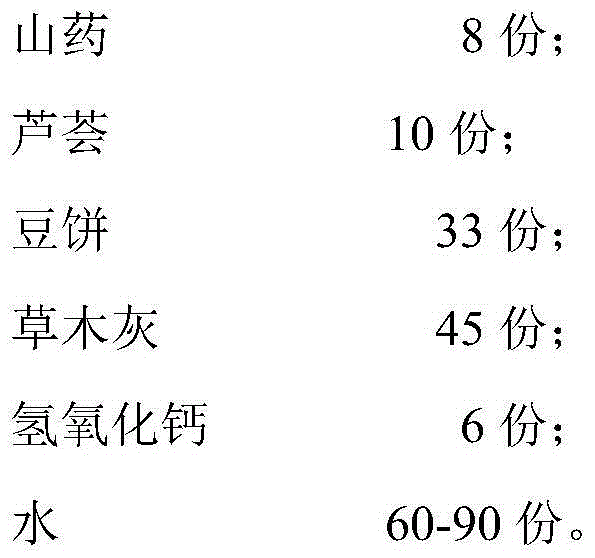

Embodiment 2

[0037] Each component was weighed according to the following mass: 8 kg of yam, 9 kg of aloe, 35 kg of bean cake, 40 kg of plant ash, 5 kg of calcium hydroxide, and 150 kg of water. Mix yam, aloe, bean cake, and plant ash evenly, add 80kg of water, react for 8 days, and then add the remaining components to it to obtain the product.

[0038] The product prepared in Example 2 was tested, and the test results are shown in Table 3.

[0039] The test result of table 3 embodiment 2

[0040]

[0041]

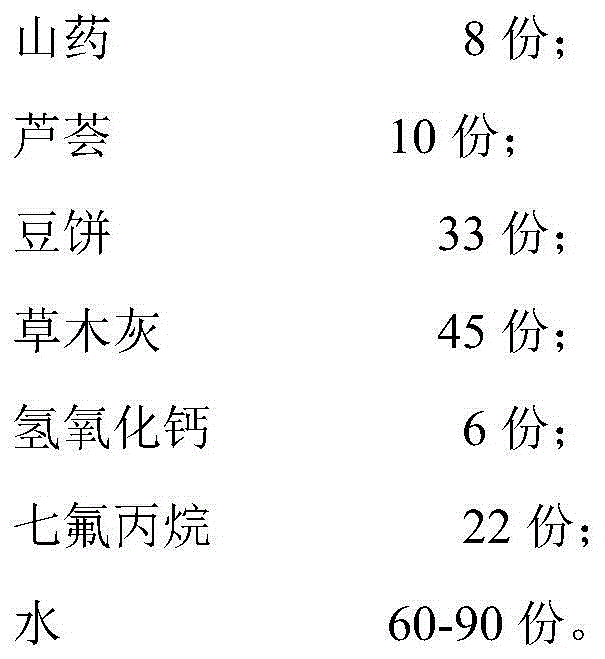

Embodiment 3

[0043] Each component was weighed according to the following mass: yam 12kg, aloe 10kg, bean cake 30kg, plant ash 55kg, calcium hydroxide 8kg, water 100kg. Mix yam, aloe, bean cake, and plant ash evenly, add 80kg of water, react for 8 days, and then add the remaining components to it to obtain the product.

[0044] The product prepared in Example 3 was tested, and the test results are shown in Table 4.

[0045] The test result of table 4 embodiment 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com