Rolling mill system with automatic adjusting function

An automatic adjustment and rolling mill technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of backward technology, high cost and long time consumption of small rolling mills, and achieve low cost and automatic adjustment High, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

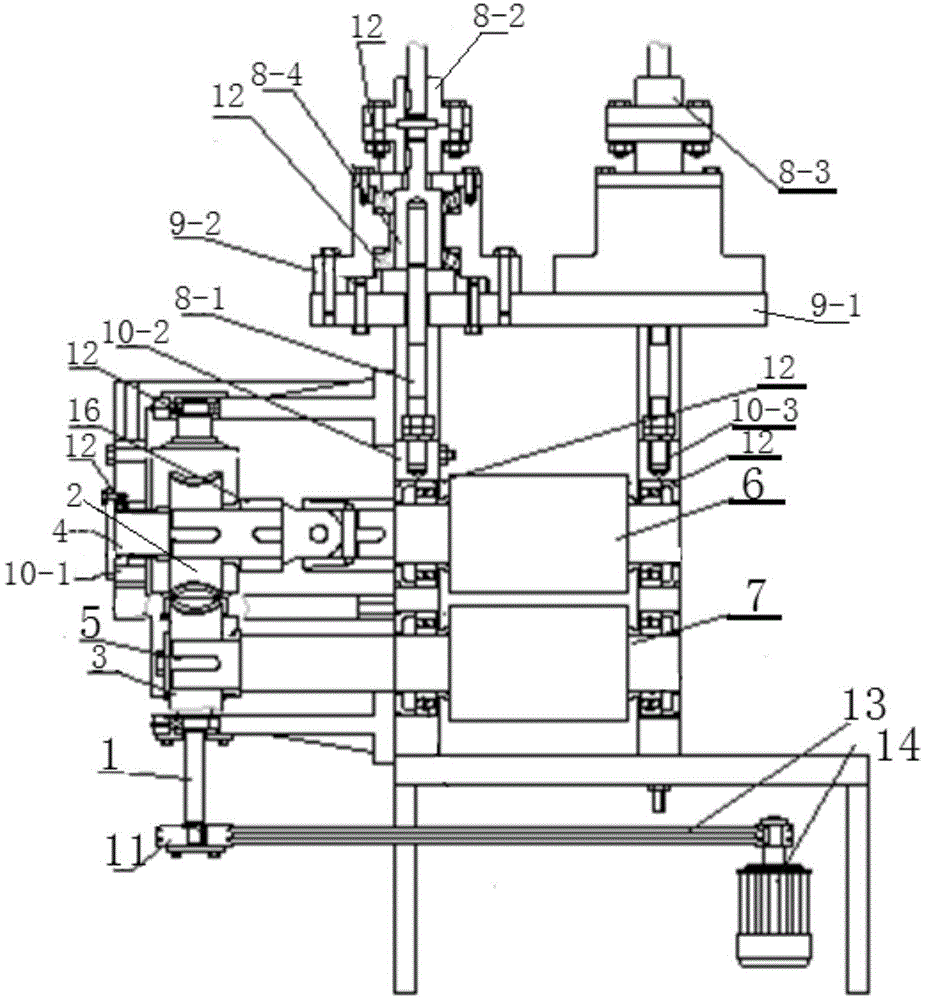

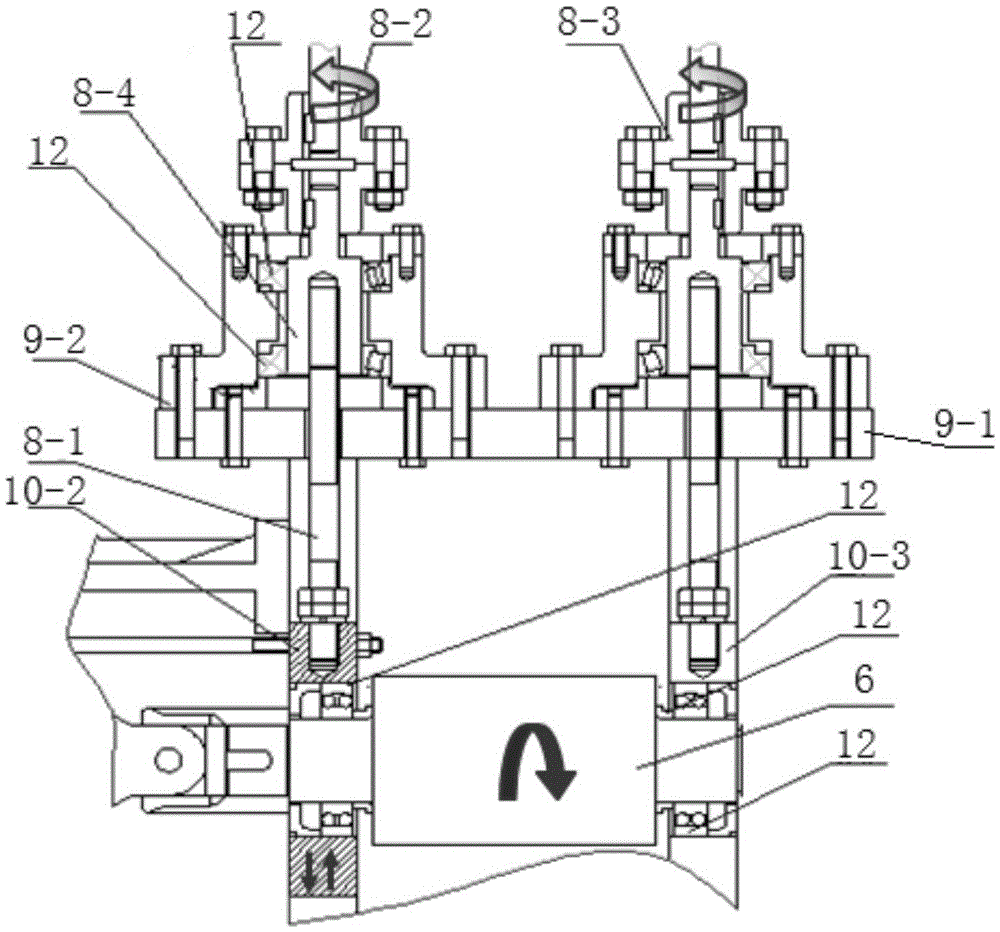

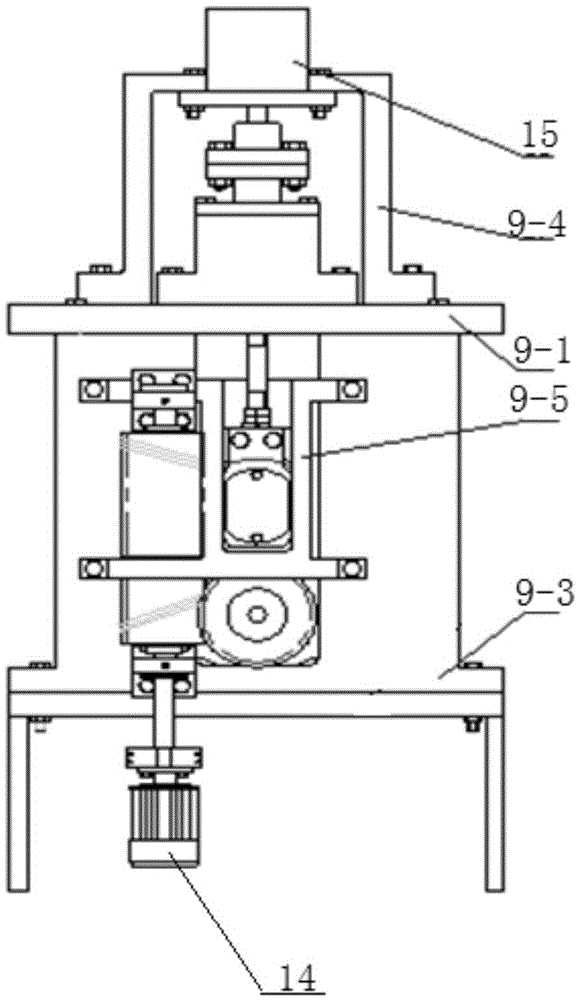

[0020] According to the above-mentioned technical scheme, the rolling mill system realizing automatic adjustment function of the present invention includes a worm shaft 1, on which a first worm wheel 2 and a second worm wheel 3 are meshed, and on the first worm wheel 2, a first worm wheel shaft 4 is arranged , the second worm gear 3 is provided with a second worm shaft 5, the first worm shaft 4 is connected to the upper roll shaft 6, the second worm shaft 5 is connected to the lower roll shaft 7, and the rolling mill system also includes an adjustment mechanism 8, which is connected to The upper roll shaft 6 and the adjusting mechanism 8 include a lead screw 8-1, the movement of the lead screw 8-1 can drive the upper roll shaft 6 to move to change the distance between the upper roll shaft 6 and the lower roll shaft 7.

[0021] The specific working principle of the rolling mill system of the present invention is as follows: the worm shaft 1 is connected to the pulley 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com