Plate shape automatic adjusting system

An automatic adjustment and plate shape technology, applied in the field of steel plate manufacturing, can solve the problems of plate shape adjustment, database update, side wave, quarter wave, medium wave, etc. that cannot be used with different racks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

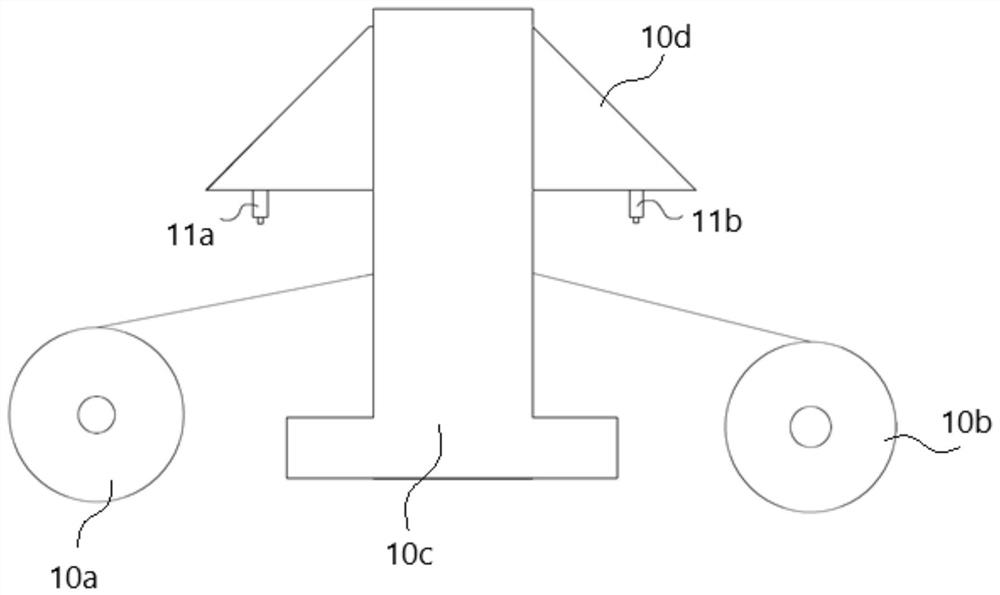

[0022] The embodiment of the invention discloses an automatic plate shape adjustment system, which is installed on a reciprocating cold-rolling machine used to produce cold-rolled steel plates. The entrance end plate shape image acquisition unit and the outlet end plate shape image acquisition unit are respectively installed on the cover, and each plate shape image acquisition unit is respectively connected with the central processing unit by communication; wherein, the plate shape automatic adjustment process of the central processing unit includes: first Receive the entrance end plate image from the entrance end plate image acquisition unit and compare it with the historical data of the database, calculate the most similar image in the database and read the adjustment data used by it, and instruct the control system of the rolling machine to proceed according to the adjustment data Adjustment; then receive the exit end plate shape image from the exit end plate shape image acq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com