Smoke exhaust gas passage device for building

A construction and airway technology, applied in the field of photovoltaic solar energy, can solve the problems of uneven product quality, unfavorable transportation and installation, and high labor intensity of workers, and achieve the effect of stable product quality, reasonable use method and exquisite structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

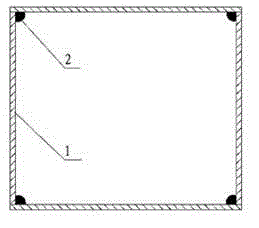

[0009] The present invention will be further explained below in conjunction with the drawings.

[0010] A smoke exhaust duct device for construction, which is characterized in that it is composed of four flat plates or two L-shaped corner plates bonded together; a combined sheet material exhaust duct can be installed with two corner walls. One surface, the other two surfaces are formed by bonding flat plates.

[0011] The application of this flue gas duct can save energy and waste, stabilize product quality, and improve production efficiency. The overall carbon reduction of the whole society is our ultimate goal, which saves social resources and has extremely high application value.

[0012] The above content is only a preferred embodiment of the present invention, and is not intended to limit the implementation of the present invention. Appropriate variations or modifications made by those skilled in the art based on the concept of the present invention should fall within the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com