Driving structure of clutch of electronic lock

A driving structure and clutch technology, which is applied in the field of electronic locks, can solve the problems of not meeting the installation requirements of anti-theft doors, inconvenient locking, and large door damage, etc., and achieve the effect of convenient and quick unlocking, convenient unlocking, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

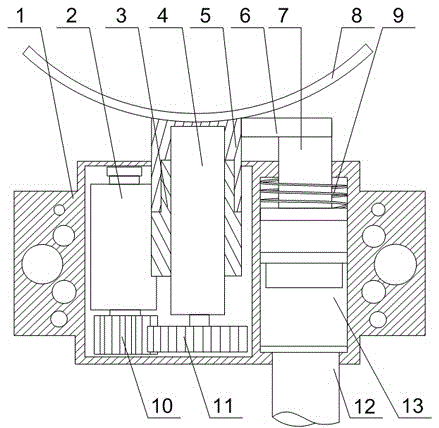

[0020] Such as figure 1 As shown, this embodiment includes a base 1 and a shrapnel 8. The inside of the base 1 is divided into an active chamber and a passive chamber. The shrapnel 8 is arc-shaped. The bottom of the shrapnel 8 is equipped with a support seat 5, and the lower end of the support seat 5 runs through The upper wall of the base 1 is placed in the passive cavity, the passive cavity is also provided with a motor 2 and a screw 4, a pinion 10 is installed on the output end of the motor 2, and a large gear 11 matched with the pinion 10 is installed on the lower end of the screw 4, and supports The lower end of the seat 5 is provided with a first blind hole, and the upper end of the screw rod 4 is slidably disposed in the first blind hole. A support block 3 threaded with it is installed on the screw rod 4, and concave holes are respectively opened on both sides of the upper end of the support block 3. Groove, the lower end surface of the support seat 5 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com