Environment-friendly type adhesive for coating printing and dyeing as well as preparation method and application thereof

An environmentally friendly adhesive technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of environmental pollution, stickiness, easy yellowing, etc., achieve natural color, improve easy yellowing, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

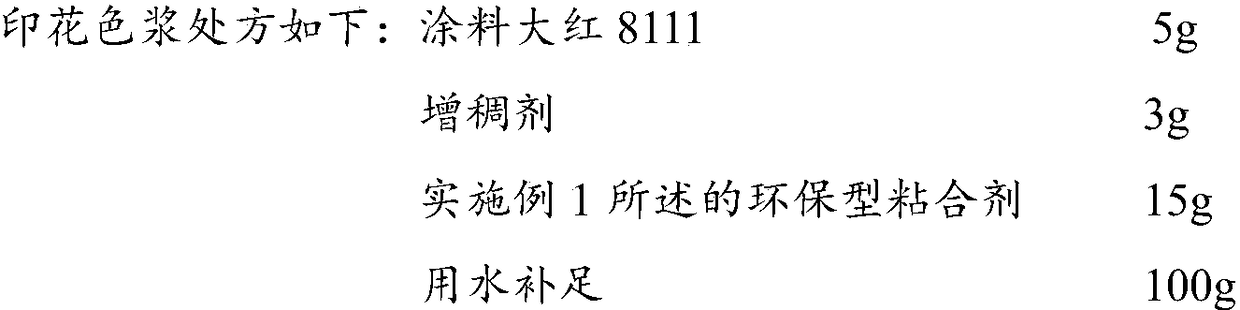

Examples

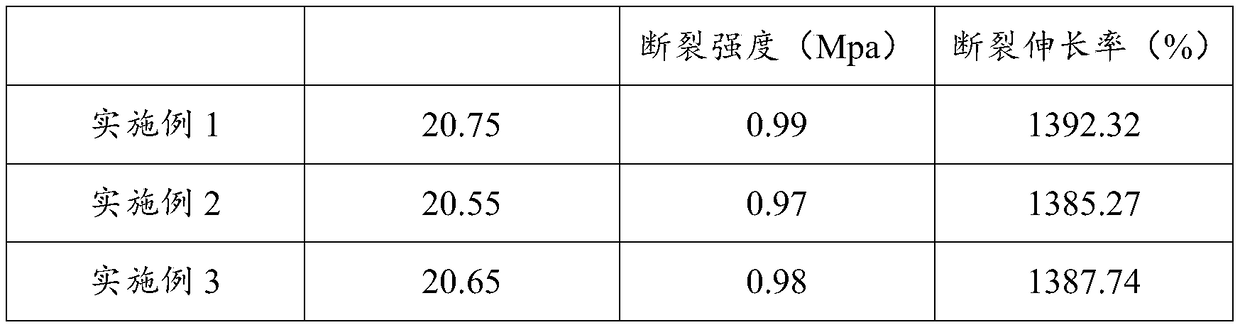

Embodiment 1

[0027] An environment-friendly adhesive for paint printing and dyeing, characterized in that it is formed by reacting the following components by weight: 55 parts of soft monomer, 15 parts of hard monomer, 7 parts of crosslinking monomer, 7 parts of cationic monomer, copolymerized monomer 8 parts of body, 2 parts of emulsifier, 0.4 part of initiator, 0.2 part of formaldehyde scavenger, 100 parts of soft water.

[0028] (1) Soft monomer: butyl acrylate, glycidyl acrylate and glycidyl acrylate are mixed with butadienoic acid;

[0029] (2) Hard monomer: mixed use of methyl methacrylate and acrylonitrile and styrene;

[0030] (3) Cross-linking monomer: mixed use of methacrylic acid and ethylene glycol glycerol dimethacrylate;

[0031] (4) comonomer: the reactant of selenous acid and 4-(2-ethylamino)benzene-1,2-diphenol and xanthan gum;

[0032] (5) Emulsifier: a compound of cationic surfactant, zwitterionic surfactant and nonionic emulsifier; the cationic surfactant is didodecan...

Embodiment 2

[0040] An environmentally friendly adhesive for paint printing and dyeing, characterized in that it is produced by the following components by weight: 50 parts of soft monomer, 10 parts of hard monomer, 8 parts of crosslinking monomer, 8 parts of cationic monomer, copolymerized monomer 7 parts of body, 1 part of emulsifier, 0.3 part of initiator, 0.1 part of formaldehyde scavenger, 80 parts of soft water.

[0041] (1) Soft monomer: Glycidyl acrylate and glycidyl acrylate are mixed with butadienoic acid;

[0042] (2) Hard monomer: mixed use of methyl methacrylate and acrylonitrile and styrene;

[0043] (3) Cross-linking monomer: mixed use of methacrylic acid and ethylene glycol glycerol dimethacrylate;

[0044] (4) comonomer: the reactant of selenous acid and 4-(2-ethylamino)benzene-1,2-diphenol and xanthan gum;

[0045] (5) Emulsifier: a compound of cationic surfactant, zwitterionic surfactant and nonionic emulsifier; the cationic surfactant is triethanolamine monooleate, 3-...

Embodiment 3

[0053] An environmentally friendly adhesive for paint printing and dyeing, characterized in that it is produced by the following components by weight: 60 parts of soft monomer, 20 parts of hard monomer, 8 parts of crosslinking monomer, 7 parts of cationic monomer, copolymerized monomer 8 parts of body, 3 parts of emulsifier, 0.5 part of initiator, 0.3 part of formaldehyde scavenger, 120 parts of soft water.

[0054] (1) Soft monomer: mixed use of glycidyl acrylate and butadienoic acid;

[0055] (2) Hard monomer: mixed use of methyl methacrylate and acrylonitrile and styrene;

[0056] (3) Cross-linking monomer: mixed use of methacrylic acid and ethylene glycol glycerol dimethacrylate;

[0057] (4) comonomer: the reactant of selenous acid and 4-(2-ethylamino)benzene-1,2-diphenol and xanthan gum;

[0058] (5) Emulsifier: a compound of cationic surfactant, zwitterionic surfactant and nonionic emulsifier; the cationic surfactant is polyepichlorohydrin-dimethylamine; the zwitterio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com