Pivot assembly bearing and disk drive device

A technology of bearings and pivots, applied in the field of sealing structures based on sealing gaps, which can solve the problems of high cost of magnetic fluid sealing, special procedures required, and inability to completely suppress dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0024] [1] Configuration of one embodiment

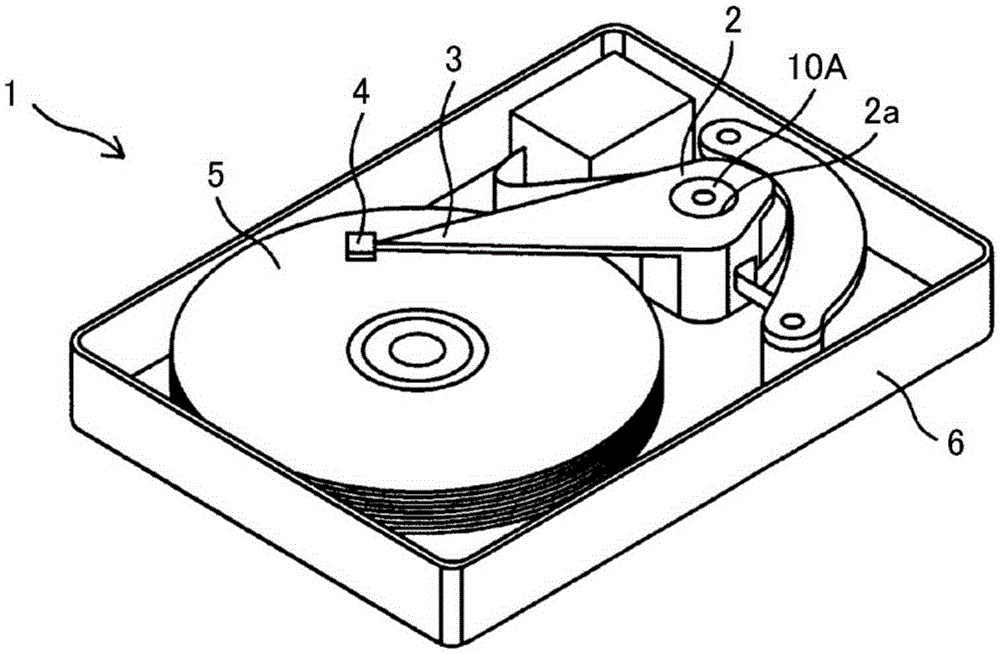

[0025] Figure 1A It shows the hard disk drive device 1 which is one of the storage devices of a computer to which the pivot mounting bearing 10A which concerns on one embodiment is applied. In this hard disk drive device 1, by setting the Figure 1B The shown pivot mounting bearing 10A supports the magnetic head 4 at the tip of the head arm 3 so as to move on the magnetic disk 5 to store information on the magnetic disk 5 and to read the stored information from the magnetic disk 5 .

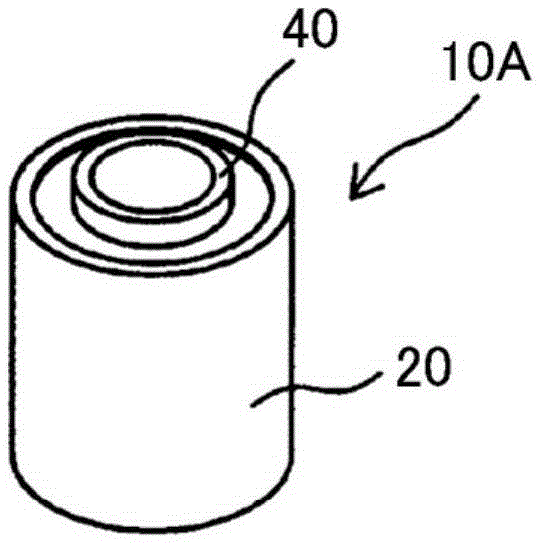

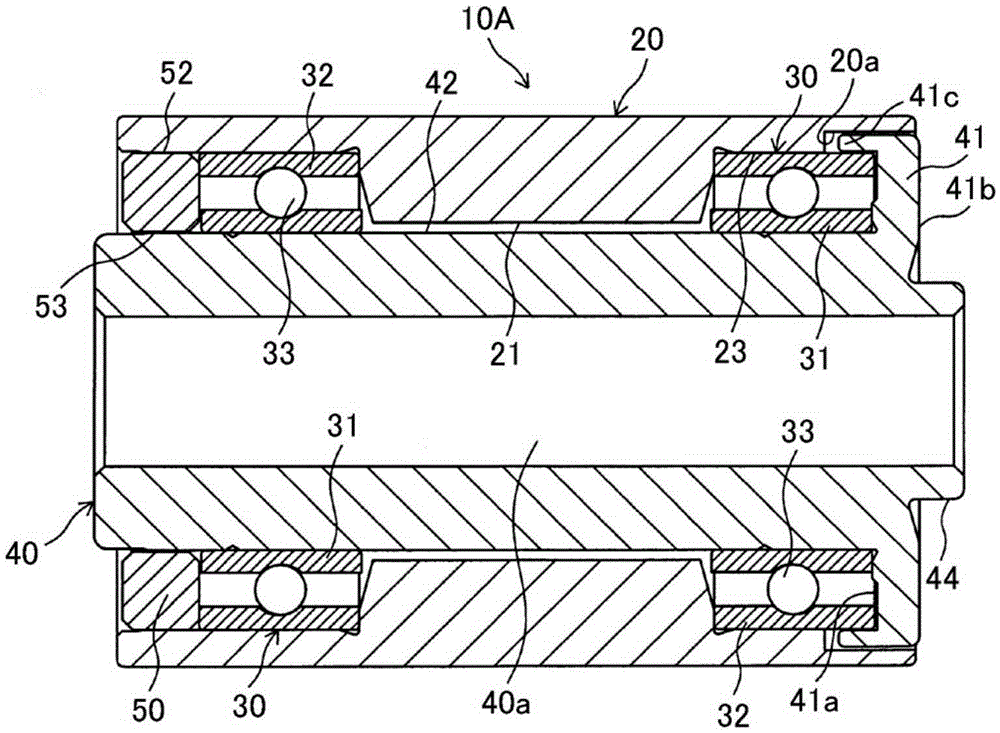

[0026] Such as Figure 1B as well as figure 2 As shown, the pivot mounting bearing 10A is a bearing device in which the sleeve 20 and the shaft 40 are relatively rotatable by inserting the shaft 40 into the rolling bearing 30 arranged inside the cylindrical sleeve 20 .

[0027] The shaft 40 of the pivot mount bearing 10A is fixed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com