Brake caliper leaf spring and brake caliper assembly

A technology of brake caliper and spring plate, applied in the direction of brake type, brake actuator, brake components, etc., can solve problems such as drag torque and pollution of the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

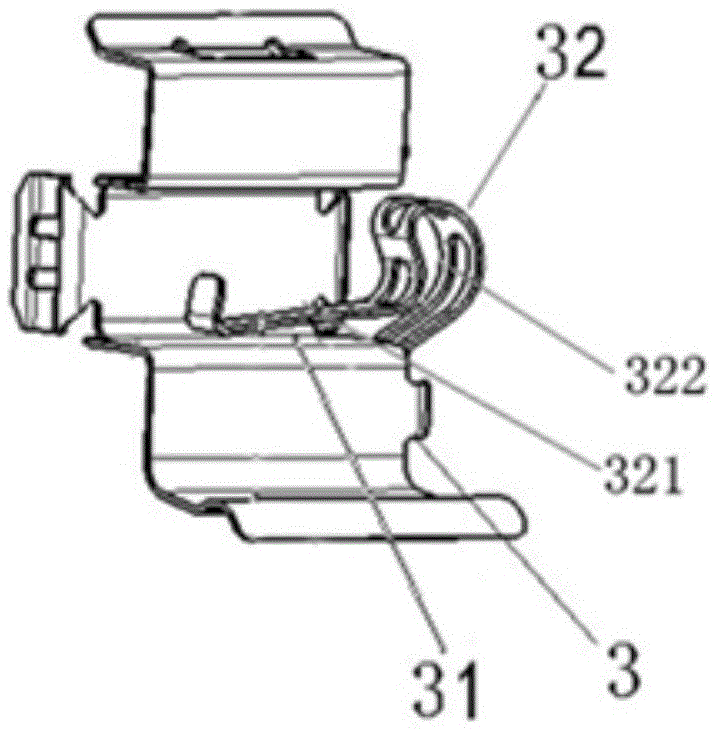

[0020] Such as figure 1 As shown: the present invention provides a brake caliper spring piece, which includes a spring piece body, a friction piece installation part 31 is arranged on the spring piece body, and a return hook 32 is arranged inside the friction piece installation part 31, and the return hook 32 Used to pull the pads back into place after braking.

[0021] Preferably, the return hook 32 includes a clamping portion 321 and a connecting portion 322, the clamping portion 321 is preferably groove-shaped, and is used for clamping with the friction plate, one end of the clamping portion 321 is connected to one end of the connecting portion 322, The other end of the clamping portion 321 is a free end, and the other end of the connection portion 322 is connected to the friction plate installation portion 31, so that the return hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com