Brake control mechanism and tractor

A brake control and brake technology, applied in the direction of brakes, brake transmission devices, foot start devices, etc., can solve the problem of easy wear of friction linings and other problems to achieve the effect of improving braking comfort, saving driving costs, and preventing drag torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

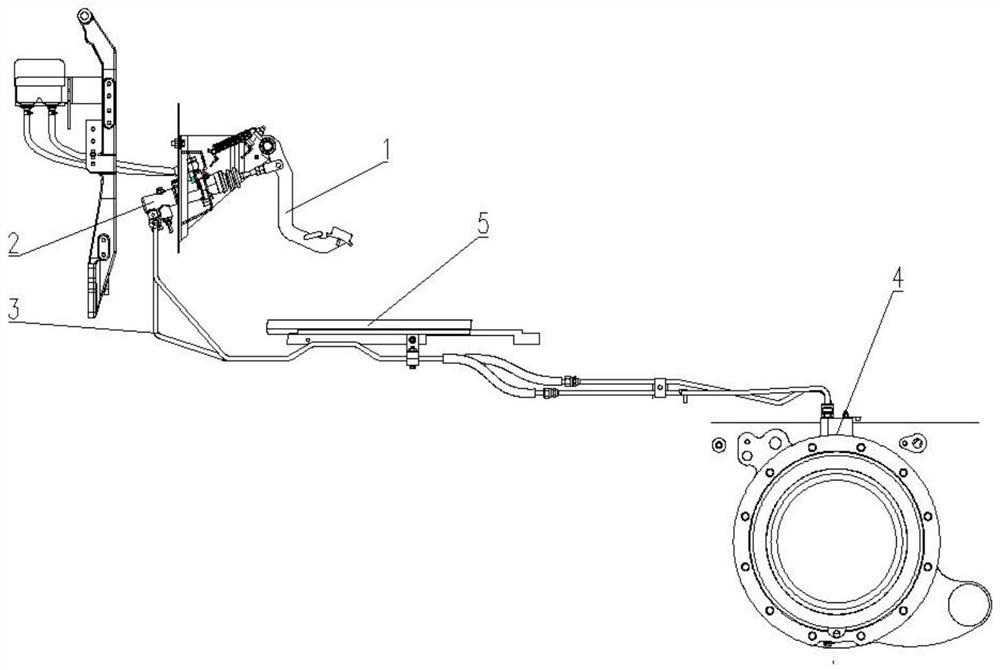

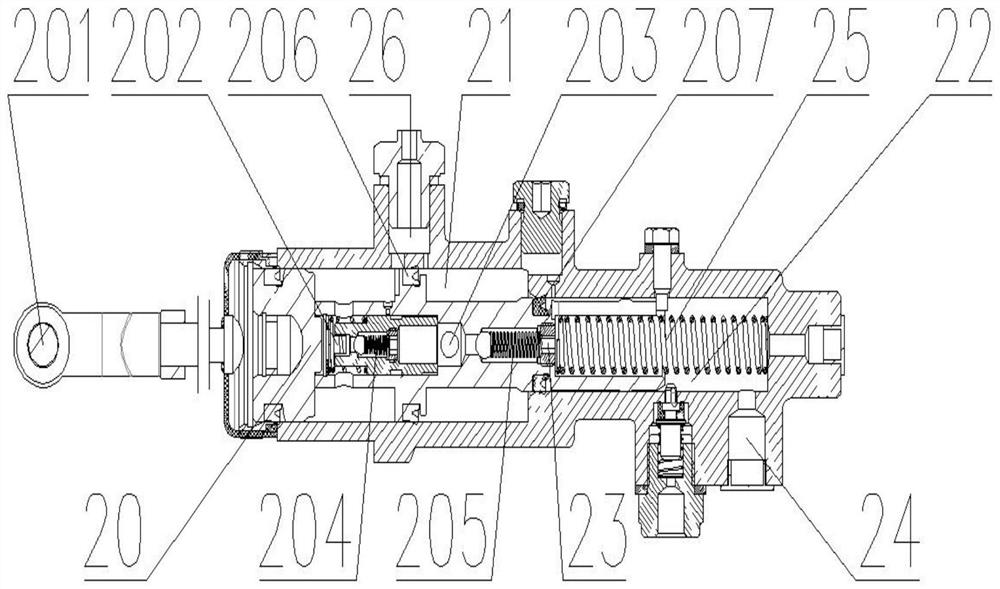

[0047] Embodiment 1: as Figure 1-2 Shown, the embodiment of a kind of brake manipulation mechanism and tractor disclosed by the present invention, comprises:

[0048] Brake pedal 1, dual-stage brake pump 2, brake oil pipe 3 and return compensation brake 4;

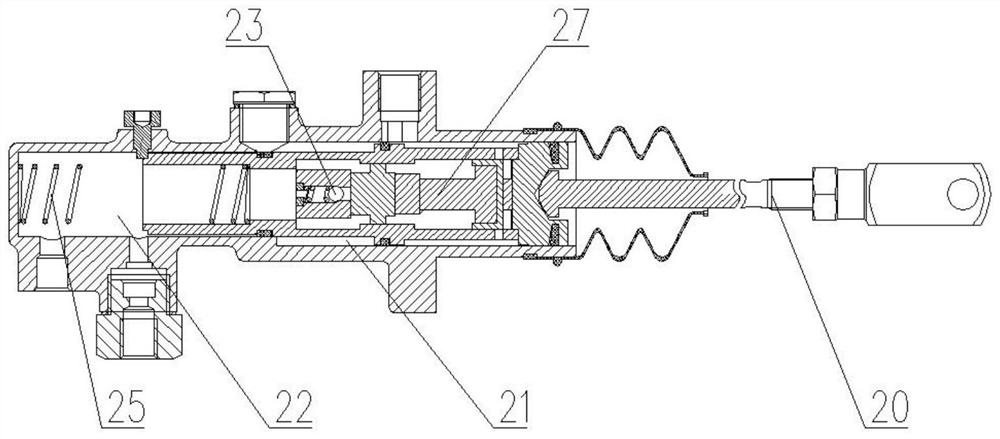

[0049] The two-stage brake pump 2 is formed with a first piston chamber 21 and a second piston chamber 22 which are sequentially arranged and communicated in the axial direction. The inner diameter of the first piston chamber 21 is larger than the inner diameter of the second piston chamber 22 . And the second piston chamber 22 is provided with a piston assembly 20, the piston assembly 20 is provided with a passage 23 communicating with the first piston chamber 21 and the second piston chamber 22, and the second piston chamber 22 is provided with a fixed connection with the passage 23. The elastic support member 25;

[0050] The brake pedal 1 is connected to the piston assembly 20 of the dual-stage brake pump 2 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com