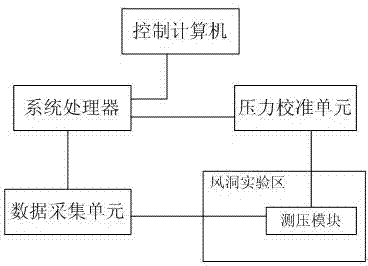

A method for automatic fault diagnosis and inspection of electronic scanning valve pressure measurement system

A technology of electronic scanning and system failure, applied in the measurement of fluid pressure, measurement device, aerodynamic test, etc., can solve the problems of failure to expose, large temperature fluctuation, difficult sensor judgment, etc., to achieve automatic identification and intelligent diagnosis , the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

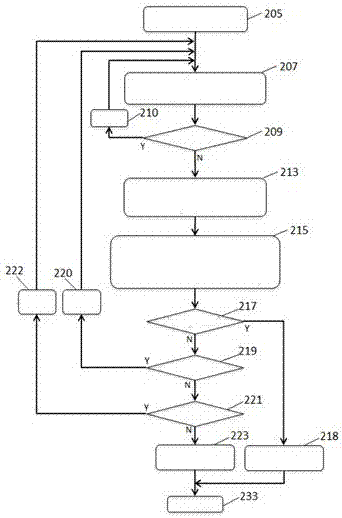

[0039] The present invention will be further described below through specific implementation examples.

[0040] If a wind tunnel has a total of 32 pressure measurement modules with 64 points, and a certain test, the total number of pressure measurement points on the model is 630 points, so this test needs to build an active pressure measurement system with at least 10 pressure measurement modules.

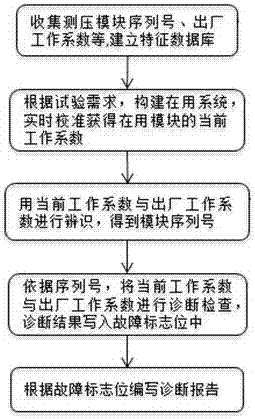

[0041] The electronic scanning valve pressure measurement system automatic diagnosis and inspection method includes the following steps:

[0042] a. Collect the serial numbers, factory work coefficients, ranges, etc. of all 32 pressure measurement modules in the electronic scanning valve pressure measurement system, and establish a characteristic database composed of the factory parameters of the 32 pressure measurement modules, m=32;

[0043] b. According to the pressure measurement requirements of 630 points in the test, 10 pressure measurement modules were selected from 32 press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com