Predictive maintenance closed-loop method based on fault mode

A technology of failure mode and closed-loop method, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as waste of information resources, production impact, and functional limitations, and achieve the effects of reducing downtime, reducing labor costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

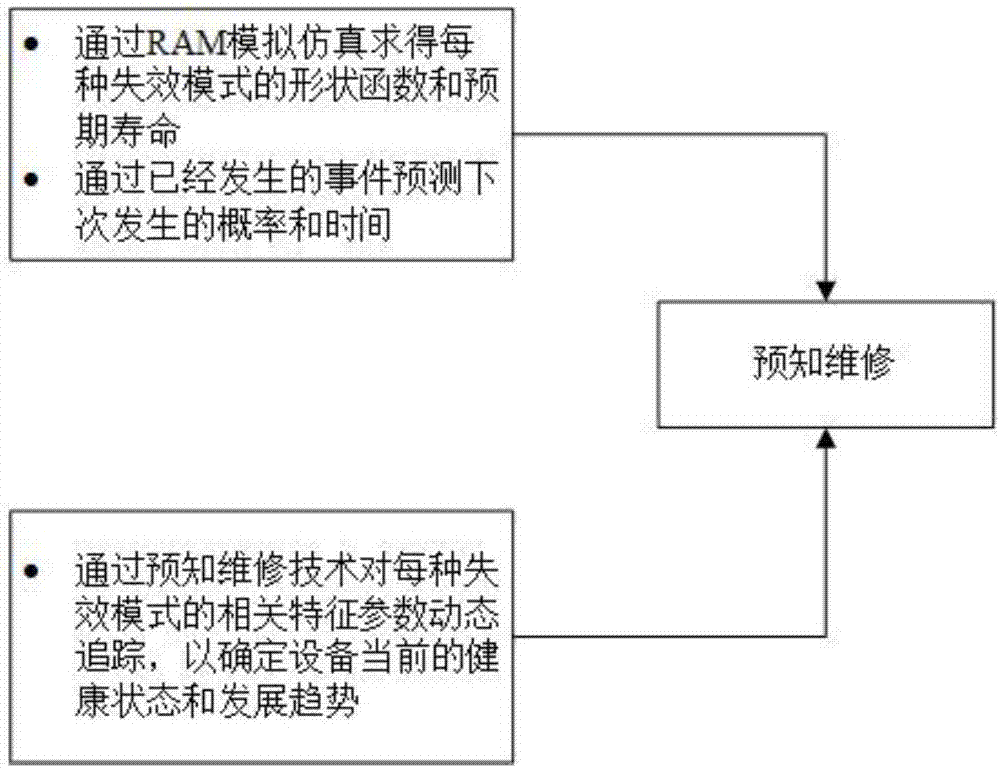

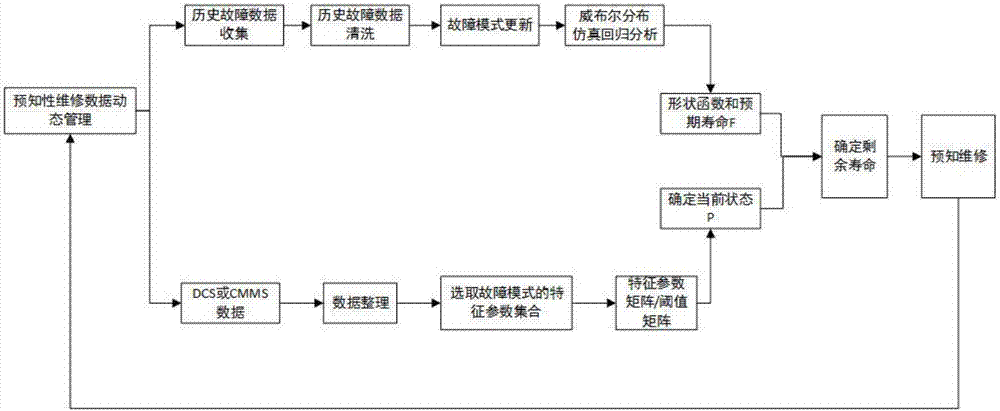

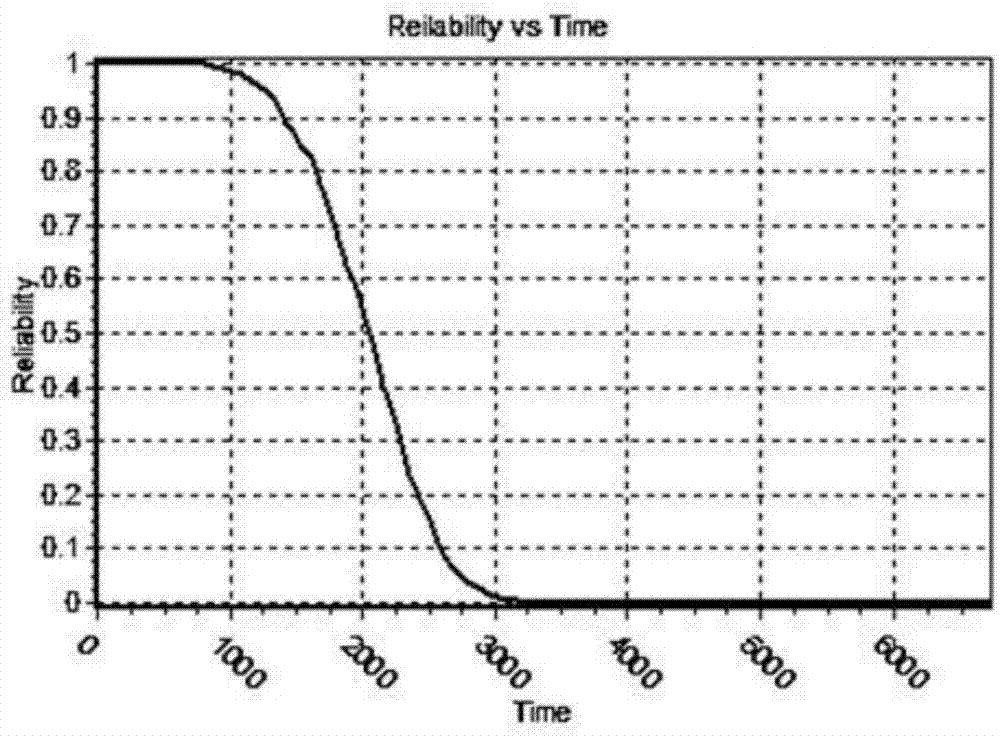

[0046] Embodiment 1, Figure 1 ~ Figure 2 A closed-loop method of predictive maintenance based on failure mode is given. The present invention corresponds the feature quantity of the predictive maintenance state monitoring to the fault mode, improves the accuracy of fault monitoring, and solves the problem that the state monitoring at the equipment level cannot clarify the fault location, and even needs to be shut down for inspection. Correspond the feature quantity of predictive maintenance status monitoring to the failure mode, take the failure mode as the node, and combine it with reliability technology to solve the problem that current predictive maintenance cannot form a closed loop, and the historical failure information of equipment in reliability technology is wasted. The problem of limited repair function.

[0047] In the predictive maintenance system that combines predictive maintenance technology and reliability technology, predictive maintenance technology predict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com