Method for producing a battery module, and battery module

A technology for battery modules and battery cells, used in batteries, secondary batteries, and final product manufacturing, etc., can solve the problems of long hardening time, difficult to achieve plastic hardening, and temperature rise, and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

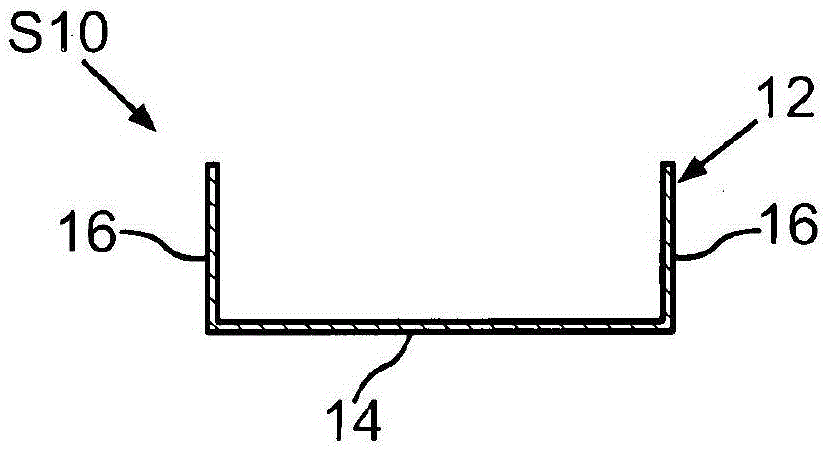

[0032] according to figure 1 description in manufacture Figure 7 A first step S10 for the battery module 10 shown in the final state. In a first step S10 , an empty module housing 12 is provided, which currently has a bottom 14 and side walls 16 . The module housing 12 forms the wall of the completed battery module 10 (see Figure 7 ). The module housing 12 is sufficiently stable so that it can absorb the forces occurring in the battery module 10 . This force, which acts in particular on the side walls 16 of the module housing 12 , originates from a chemical reaction which takes place in the individual battery cells 18 of the battery module 10 when the battery module 10 supplies a voltage.

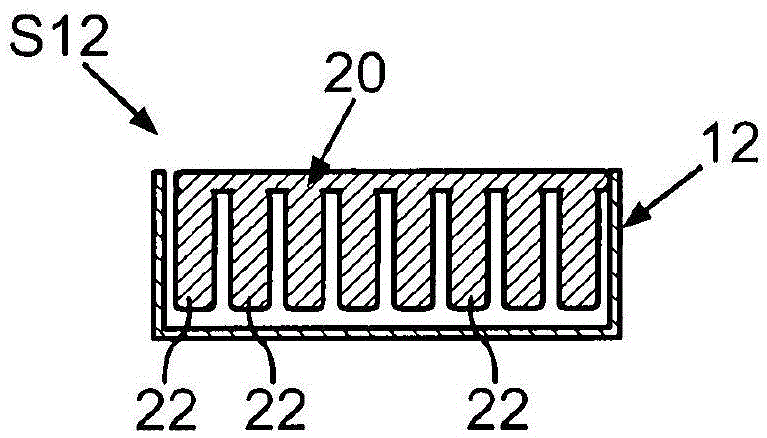

[0033] In the second step S12 (see figure 2), a core arrangement 20 comprising a plurality of cores 22 is arranged in the module housing 12 . The core 22 forms a negative mold for the electrode arrangement 24 of the individual battery cells 18 (see Figure 6 ).

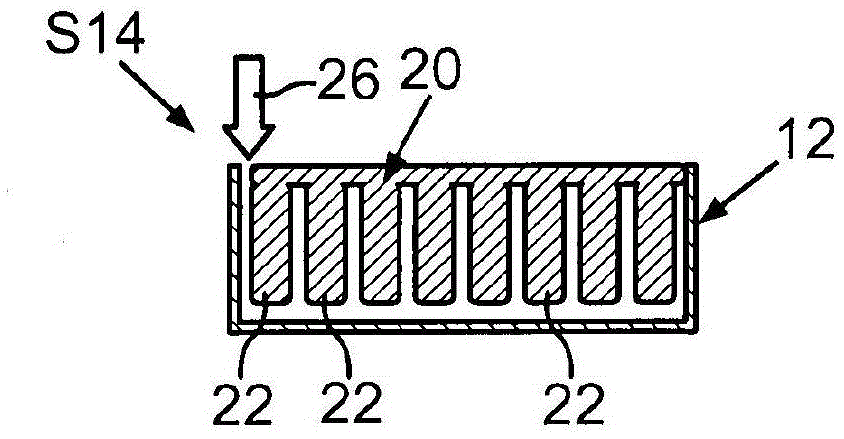

[0034] In the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com