Printing control strip with split mark

A technology of marking and measuring strips, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

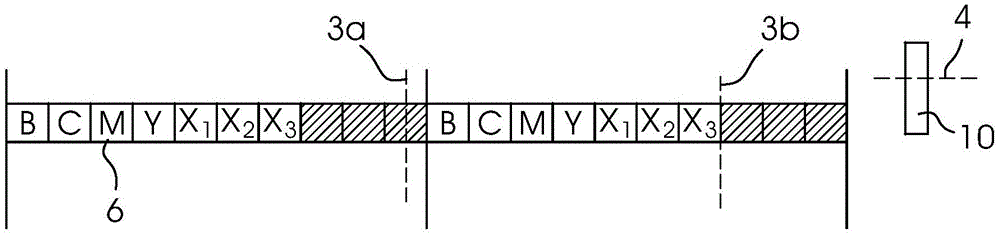

[0015] figure 1 Two adjacent ink zones 8 are shown, which each have ten ink measurement areas 6 , of which the last three ink measurement areas 6 form the peripheral marking 9 . In addition, two sensors 3 a and 3 b are provided, which are arranged offset by 7.5 times the ink measuring range.

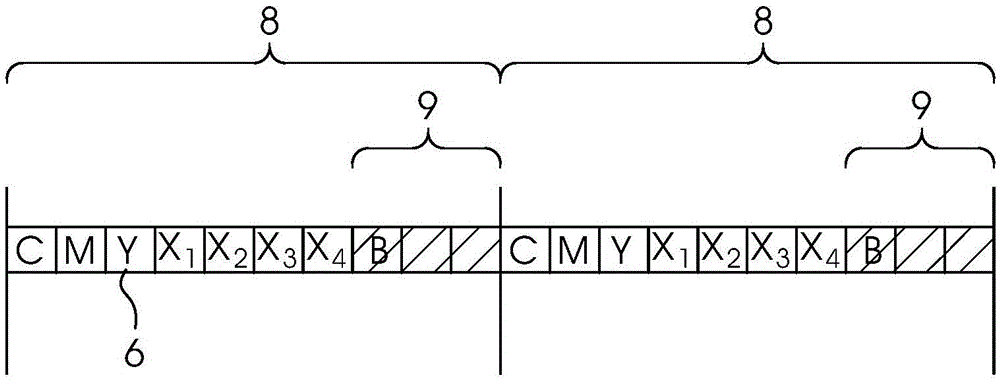

[0016] figure 2 Also shown are two adjacent ink zones 8 which each have ten ink measuring fields 6 , of which the last three ink measuring fields 6 form peripheral markings 9 , And the above-mentioned two sensors 3a and 3b are provided, which are arranged offset by 7.5 times the ink measurement area. In this case, the above-mentioned last three ink measurement regions 6 which form the peripheral marking 9 are set to be black in ink.

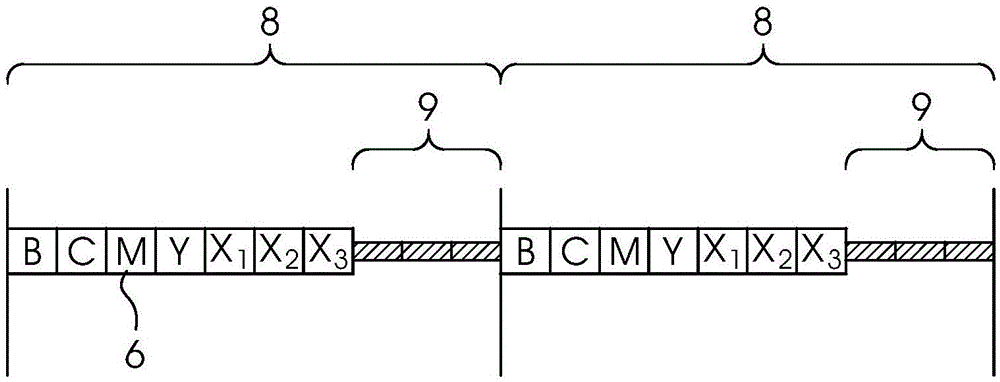

[0017] image 3 Also shown are two adjacent ink zones 8 which each have ten ink measuring fields 6 , of which the last three ink measuring fields 6 form peripheral markings 9 , And the above-mentioned two sensors 3a and 3b are provided, which are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com