A high-efficiency automobile carbon canister activated carbon filling device

A filling device and activated carbon technology, which is applied in the field of filling devices for automobile carbon canister materials, can solve the problems of carbon powder dust diffusion, prone to tilting and overturning, and the filling accuracy cannot be guaranteed, so as to improve production efficiency, Ensure fluency and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

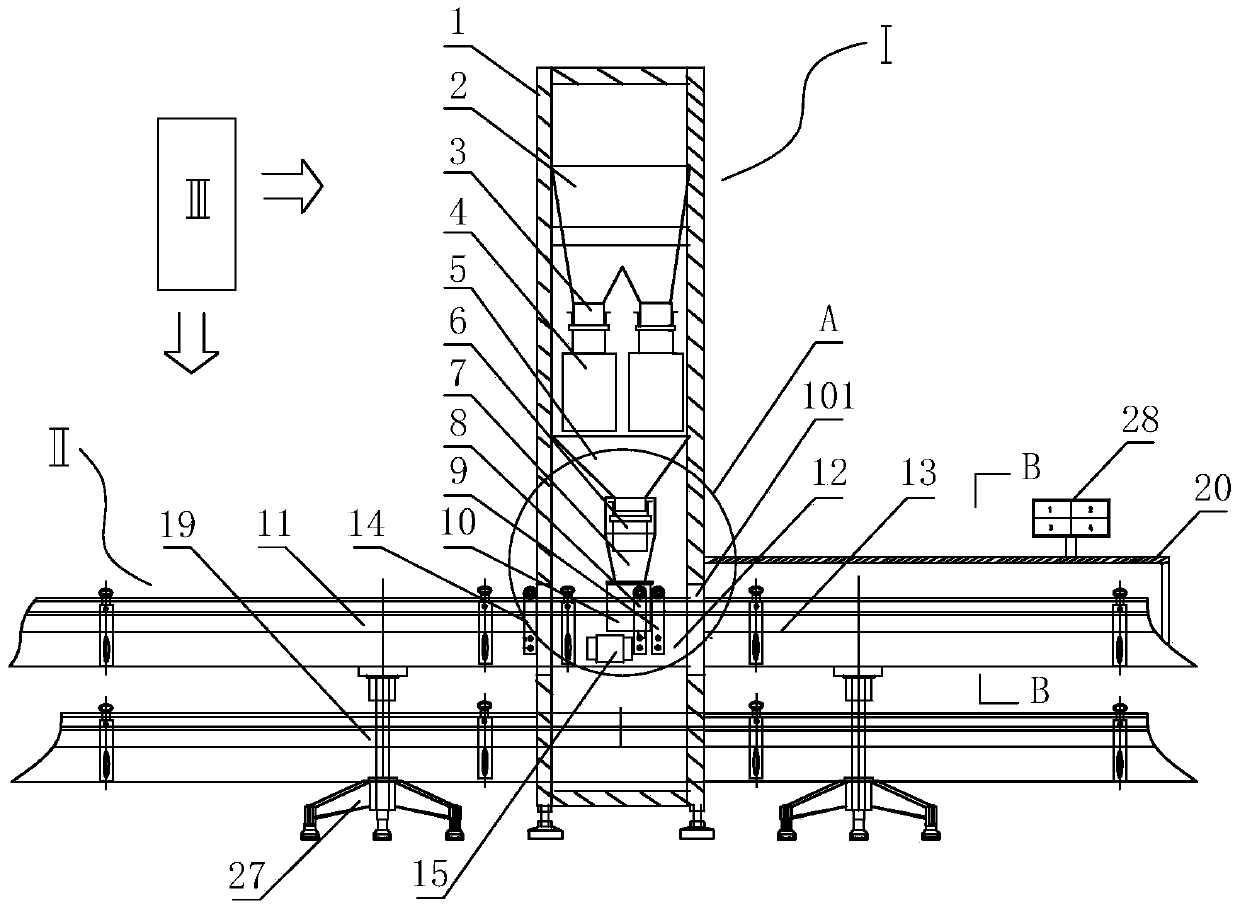

[0040] A high-efficiency activated carbon filling device for automobile canisters, including a frame and a filling mechanism I, a transmission mechanism II and a control mechanism III installed on the frame, and the transmission mechanism II and the filling mechanism I are completed under the control of the control mechanism III Tank feeding and activated carbon filling actions;

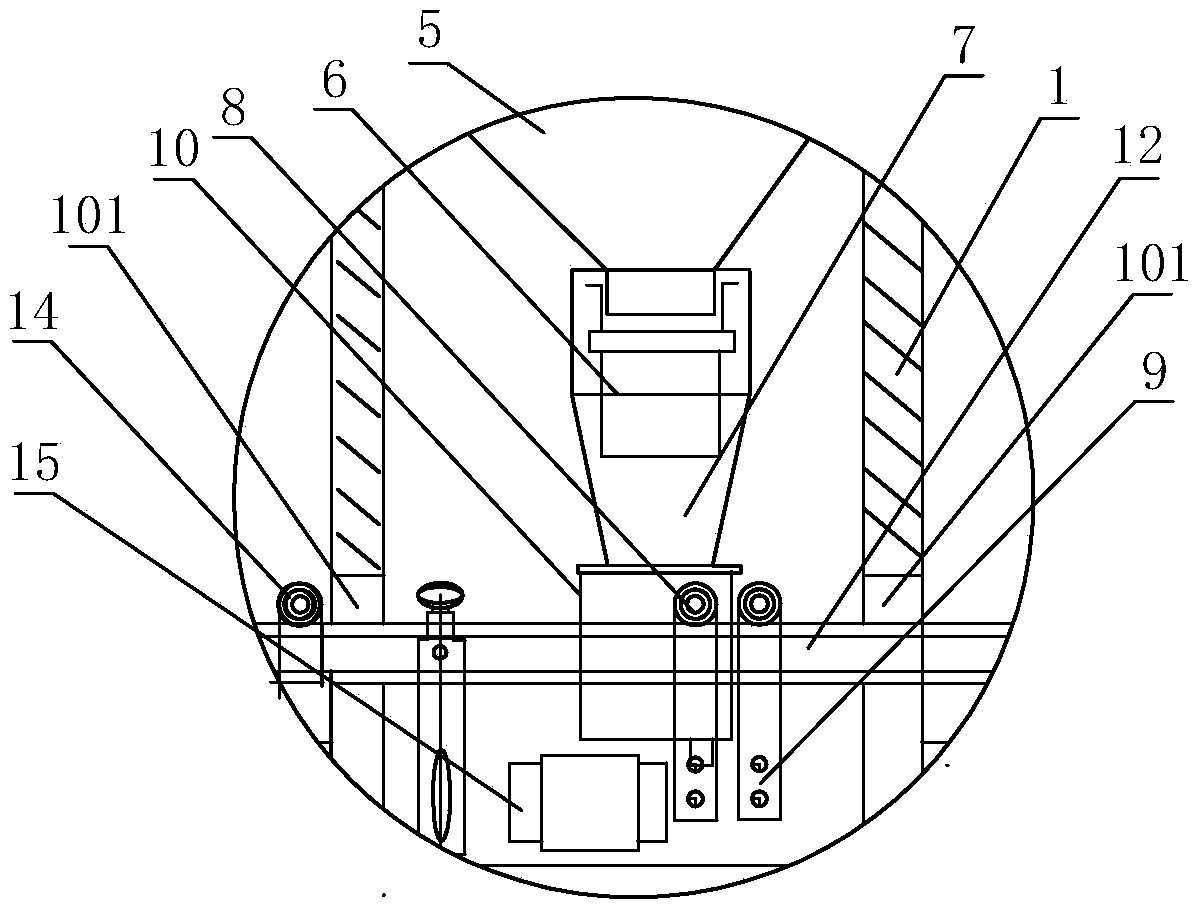

[0041] The filling mechanism I includes a material box 2, a weighing hopper 4, a lower hopper 5 and a filling hopper 7 installed in the sealed chamber 1 from top to bottom, and the upper port of the weighing hopper 4 is passed through the vibrating feeder 3 is connected with the material box 2, the lower outlet of the weighing hopper 4 is opposite to the lower hopper 5, and the leak of the lower hopper 5 is connected with the filling hopper 7 through the filling vibrating feeder 6, and the lower discharge of the filling hopper The mouth faces the carbon tank;

[0042] The conveying mechanism II incl...

Embodiment 2

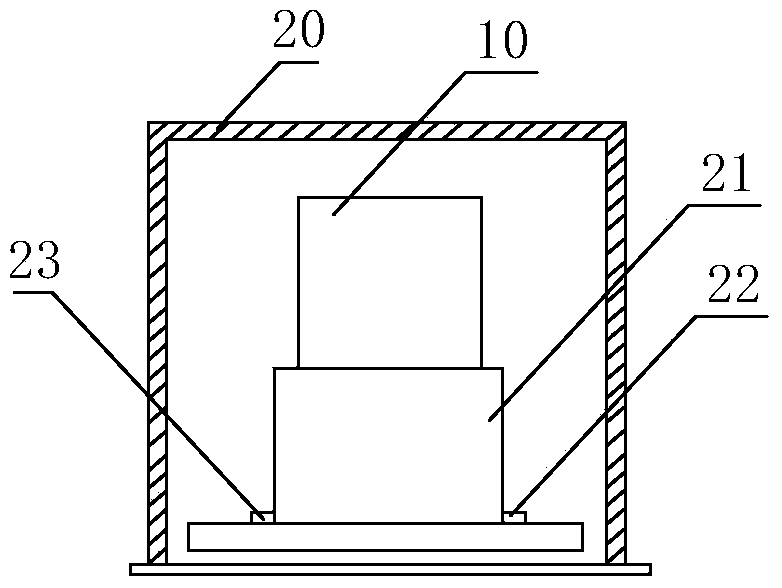

[0055] A high-efficiency automobile canister activated carbon filling device, its transmission mechanism and control mechanism are the same as in Embodiment 1, the difference is that the number of weighing hoppers, lower hoppers and filling hoppers of the filling mechanism is different, and its weighing The bucket 4 is four weighing buckets, the lower hopper 5 is a double lower hopper, and the filling bucket 7 is a double filling bucket. The lower outlets of the two weighing hoppers are facing the lower hopper 5; the leaks of the front and rear lower hoppers 5 are respectively connected with the front and rear two filling hoppers 7 through two filling vibrating feeders 6. Limit proximity switches 8 and 17 and limit cylinders 9 and 18 are respectively installed in the bottom of each filling bucket 7.

[0056] The above embodiment is one of the preferred embodiments of the present invention, wherein in embodiment two, the weighing hopper 4 of the filling mechanism is four weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com