Plastic automatic sealing bag with high sealing performance

A self-sealing bag and strong sealing technology, applied in the direction of closure devices, etc., can solve the problems of unsatisfactory sealing requirements, low fastening and opening efficiency, and insufficient sealing performance, and achieve improved fastening and opening efficiency, strong sealing, and The effect of meeting the sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

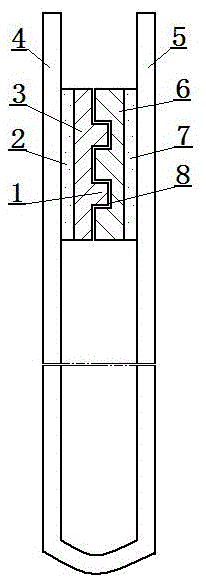

[0012] Example: such as figure 1 As shown, a plastic ziplock bag with strong airtightness is designed and manufactured. The plastic ziplock bag includes a square plastic bag body formed by folding the left bag piece 4 and the right bag piece 5 in half and heat sealing and cutting. The square plastic bag body is provided with The mouth of the bag is provided with a self-sealing device inside the mouth of the bag. The main features of the present invention are: the self-sealing device includes a left soft magnetic sheet 3 and a right soft magnetic sheet 6, the length of the left soft magnetic sheet 3 and the right soft magnetic sheet 6 Both size and width dimensions are the same and magnetically attract.

[0013] The left rubber soft magnetic sheet 3 is provided with two parallel convex strips 1 along the length direction, and the right rubber soft magnetic sheet 6 is provided with two grooves 8 corresponding to the two convex strips 1 along the length direction.

[0014] The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com