Multistage belt-type transportation centralized control device of coal cleaning plant

A technology of centralized control device and coal washing plant, applied in conveyor control device, transportation and packaging, conveyor and other directions, can solve the problems of lack of operation process characteristics, no multi-stage belt conveyor start-stop sequence and fault handling monitoring, etc. Reliable performance, perfect monitoring and protection functions, and complete functions are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

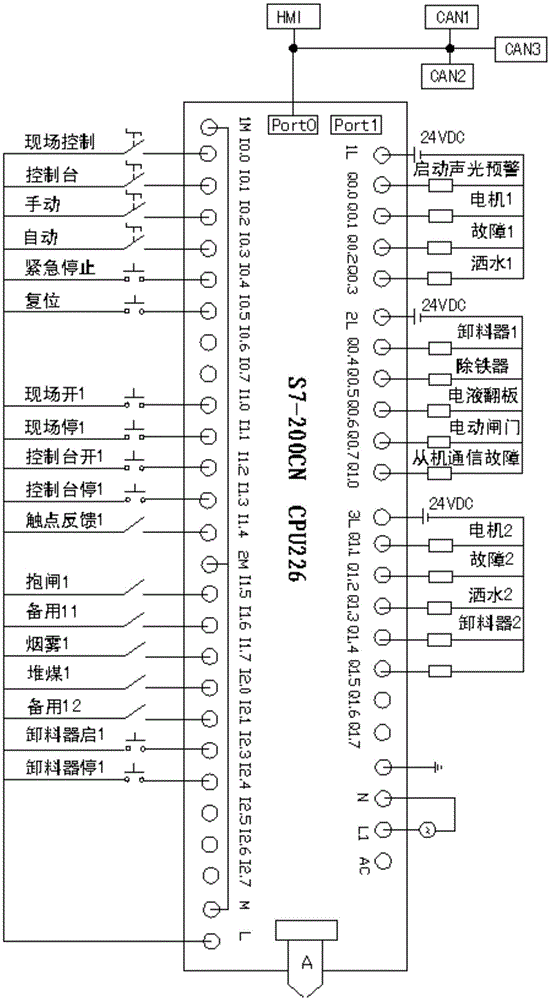

[0071] This embodiment is a four-stage belt conveyor, and the PLC used is the S7-200CN series CPU226 PLC produced by Siemens, which has two communication ports, PORT0 and PORT1 respectively. After the communication ports of touch screen 1, touch screen 2, CAN board 1, CAN board 2 and CAN board 3 are connected in parallel, they are connected to the communication port PORT0 of the PLC, and PORT1 is connected to the communication port of the upper computer.

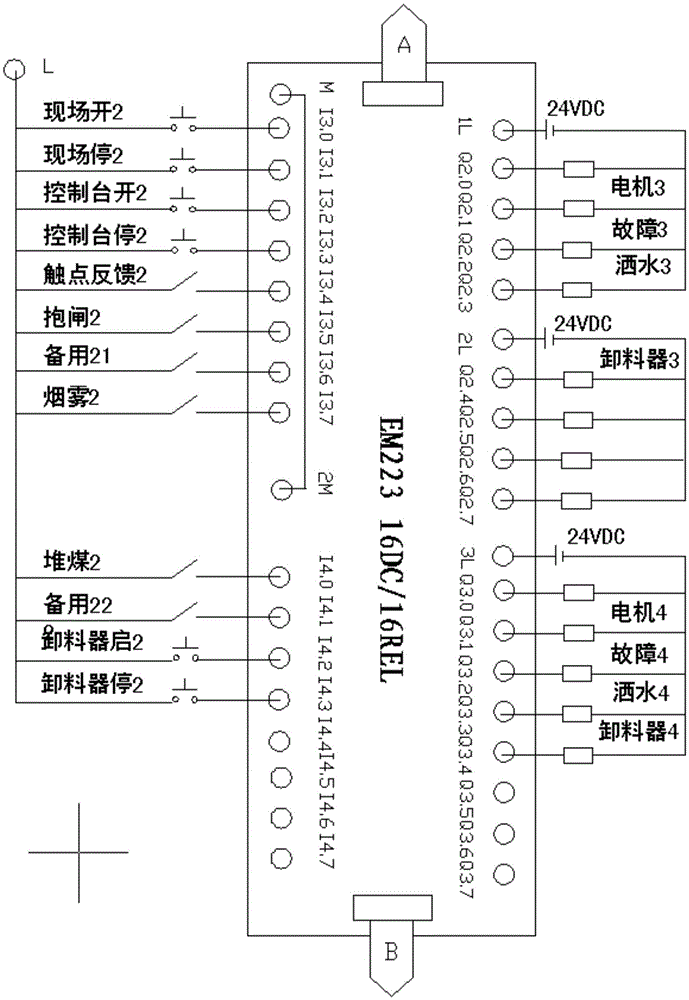

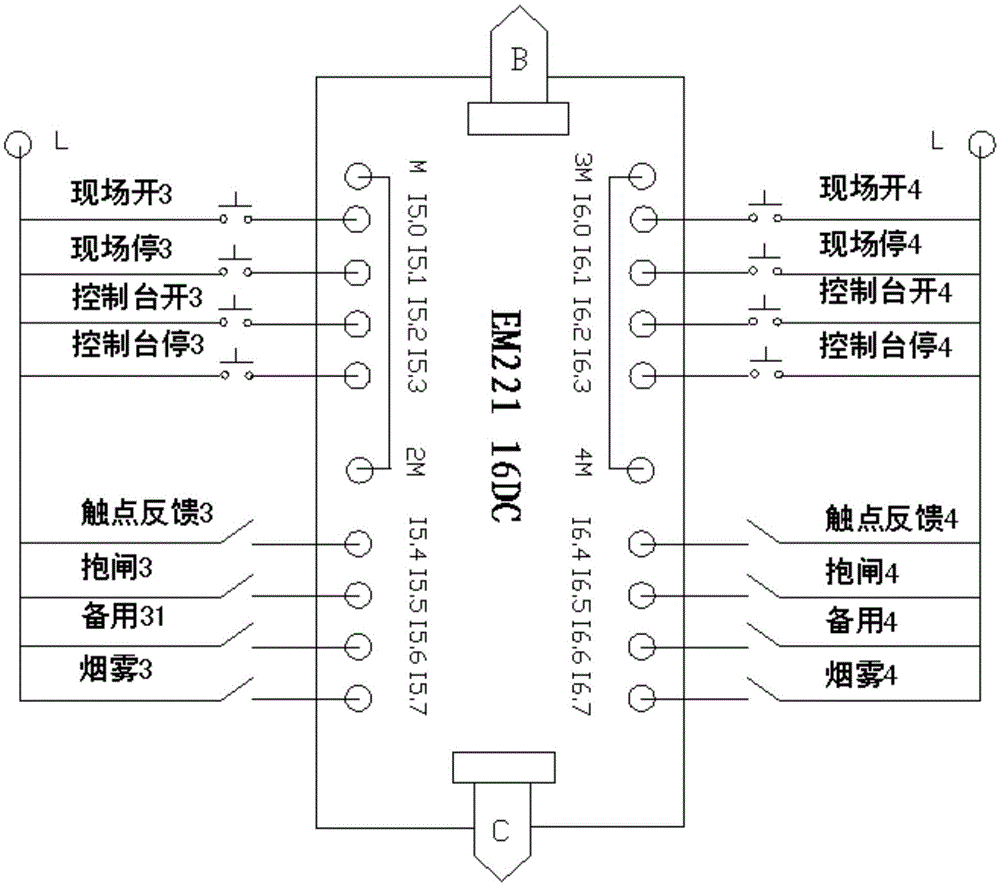

[0072] The input / output expansion module is Siemens EM223, 16DC / 16REL, the input expansion module 1 is EM221, 16DC, the input expansion module 2 is EM221, 16DC, the analog / digital conversion expansion module EM231, 4AD, the Ethernet communication expansion module is EM243 -1. The touch screen is MT4404T 10-inch touch screen produced by Shanghai Kinco Company.

[0073] In the control mode, the knob selector switch of on-site control / console control is connected to I0.0 and I0.1 of the PLC input terminal; in the operation mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com