Roller frame for accommodating sliding doors with height adjustment

A technology of roller frame and sliding door, which is applied in the field of roller frame and can solve the problems of inaccurate installation cost, long installation time, and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

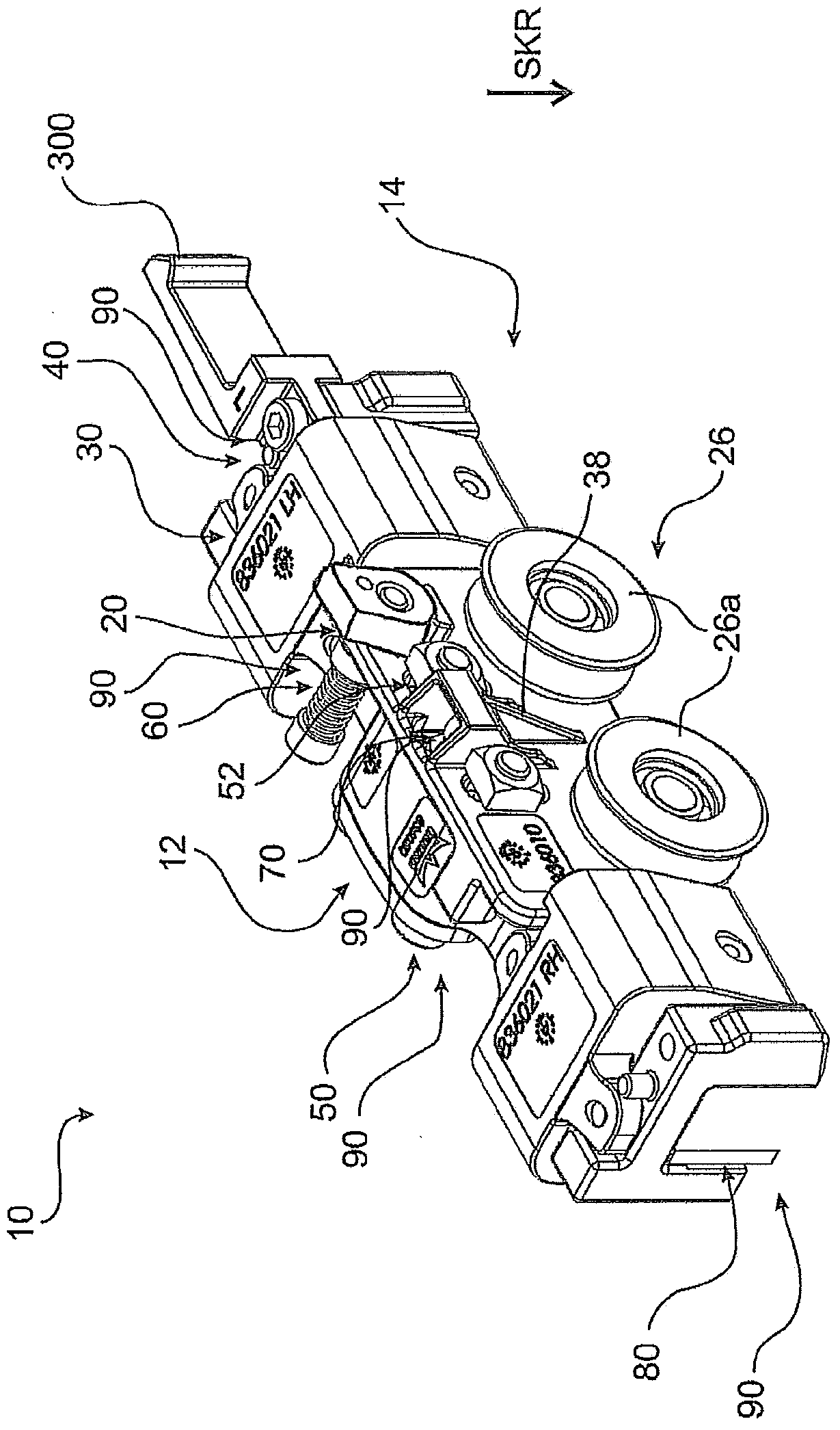

[0042] exist figure 1 An isometric view of one embodiment of a roller carriage 10 is shown in . The roller stand has two basic components. In this case, it is the roller module 20 on the one hand and the base body 30 on the other hand. The two components, ie the roller module 20 and the base body 30 , have a number of different individual parts. The individual components are explained briefly below.

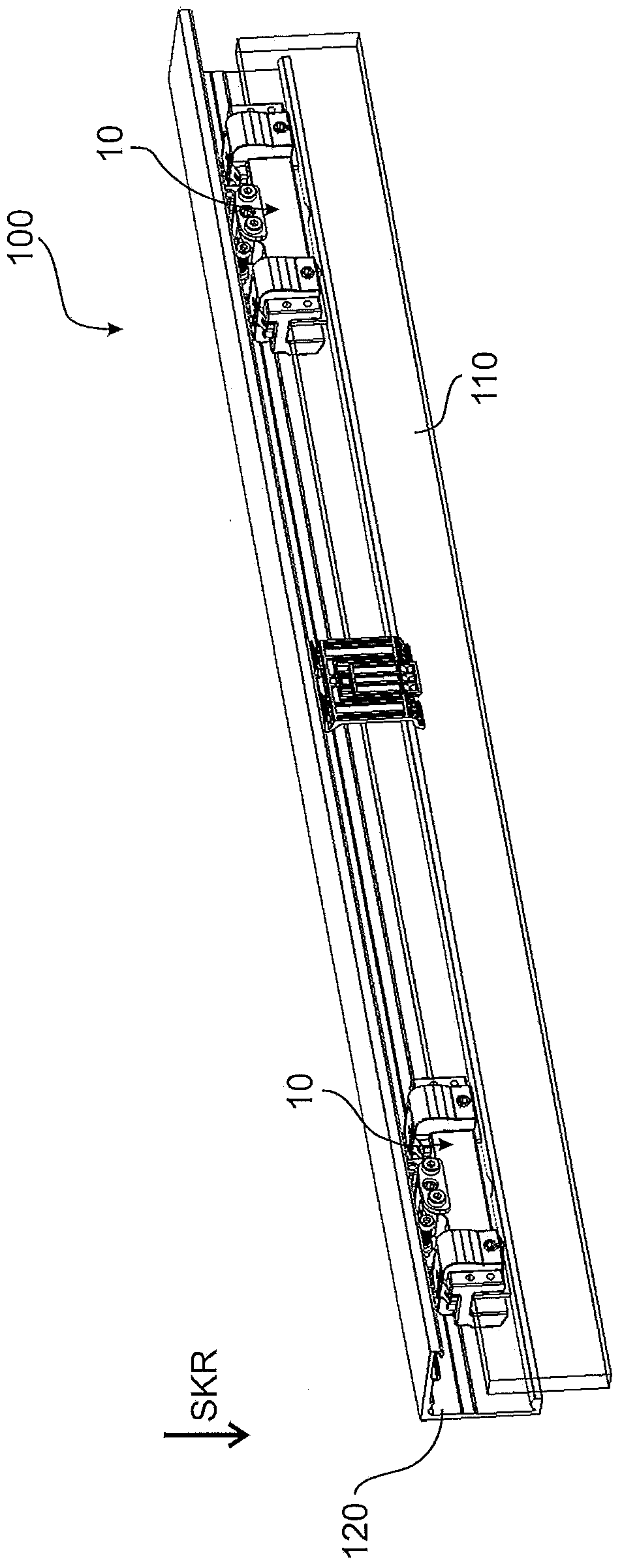

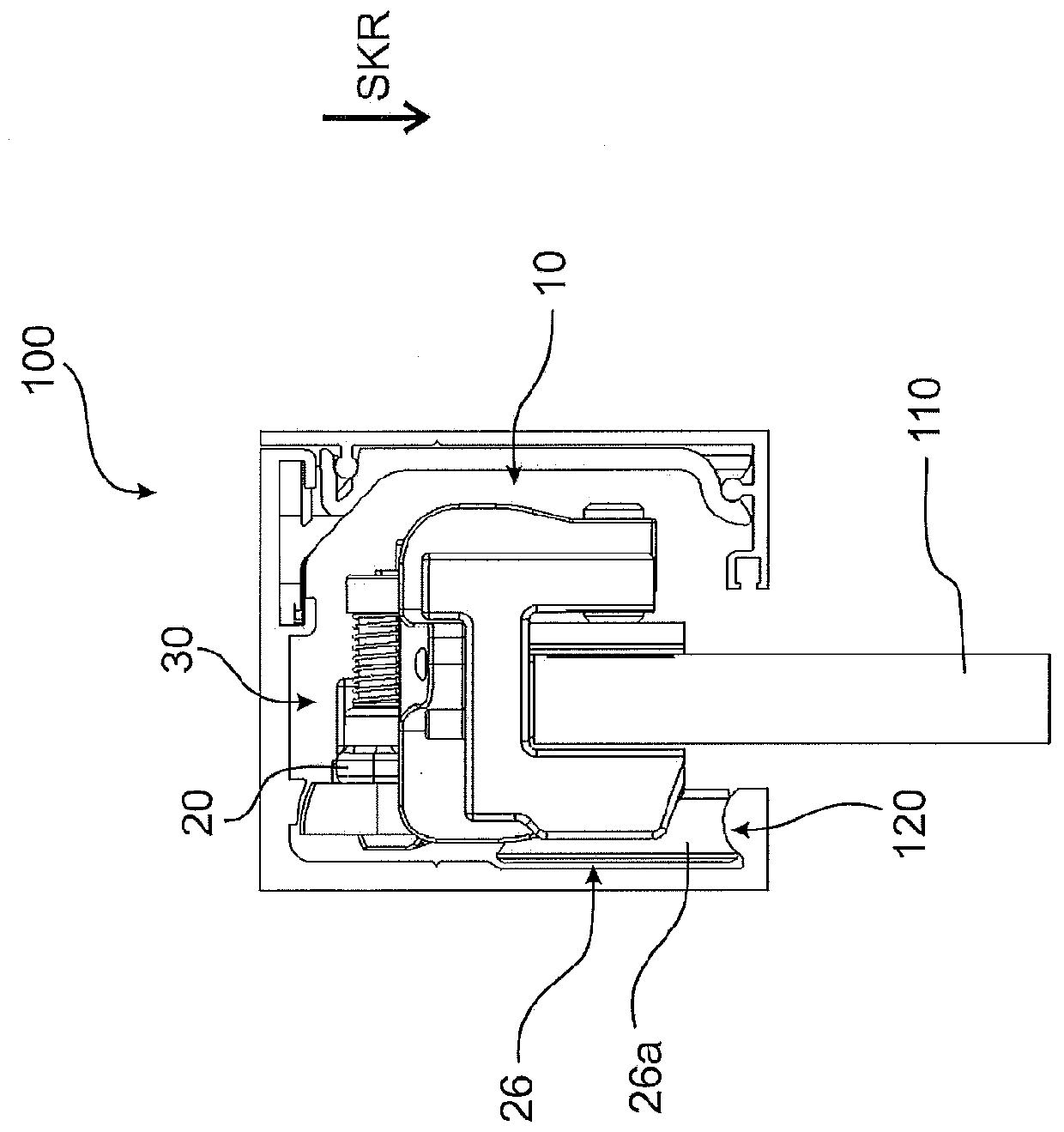

[0043] The roller module 20 is associated here with a bearing device 26 . The bearing device 26 is here provided in the form of two rollers 26 a which are rotatably mounted on the basic body of the roller module 20 . The rollers 26a can now be used in or on the roller guide 120, as can be done in figure 2 with image 3 In good visibility. Furthermore, a part of the height adjustment device 70 is provided on the roller module 20 . The detailed components of the height adjustment device 70 are especially in Figure 4 with 5shown in . A first adjusting mechanism 32 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com