Edge-on roll rack of guide pillar type pipe welder

A guide post type and pipe welding machine technology is applied to the cold bending forming production line equipment for sheet metal and the frame field of various forming technologies. constitute a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

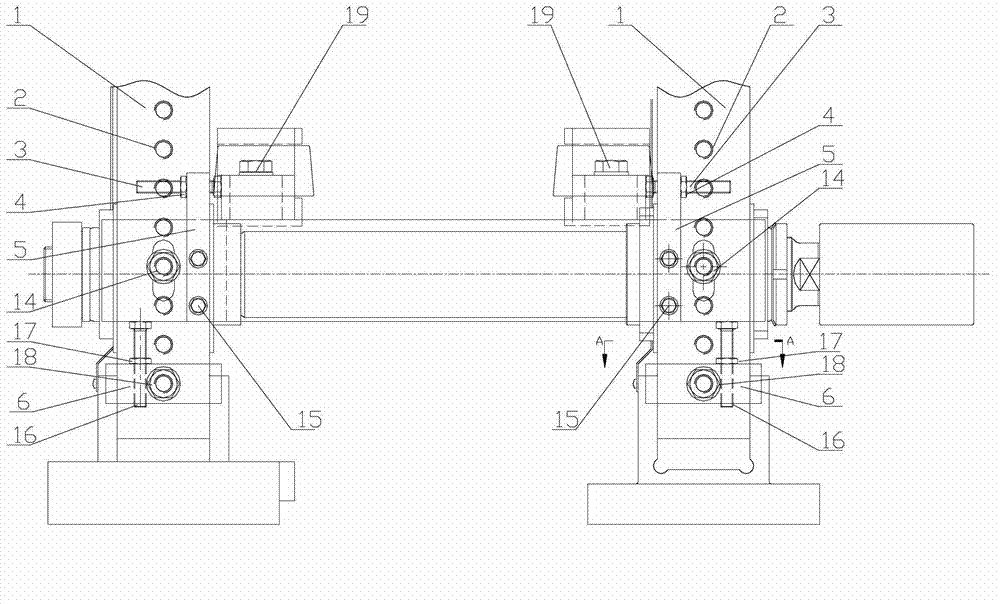

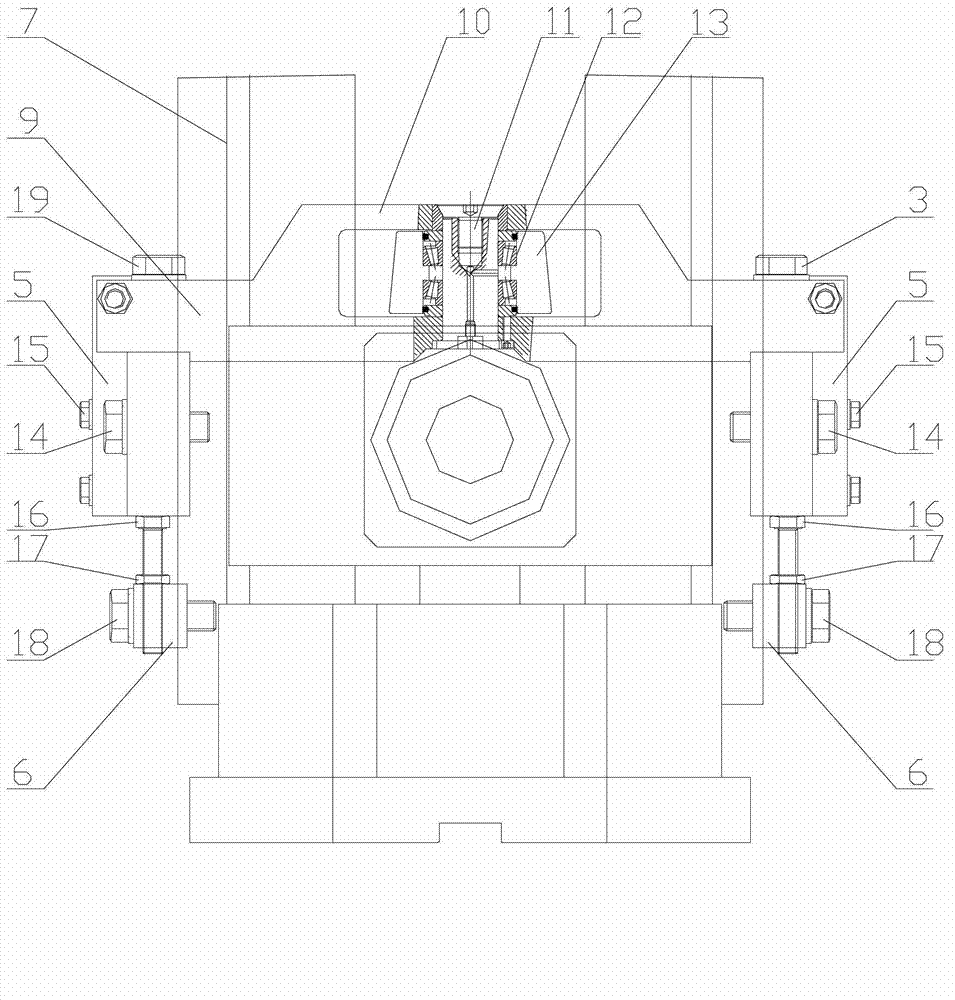

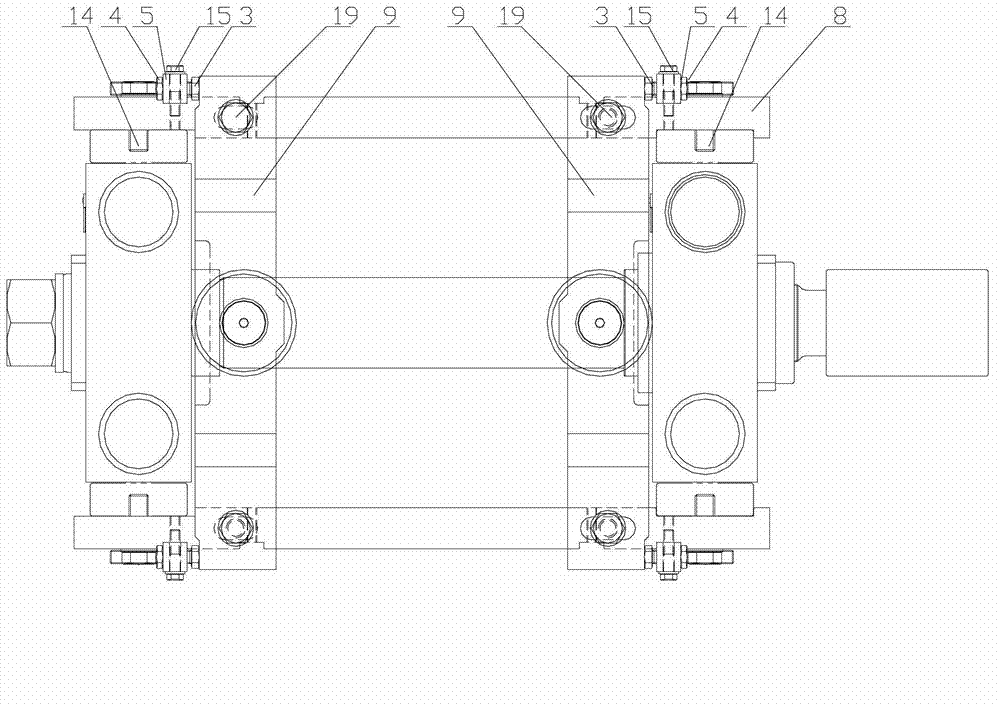

[0024] The side vertical roller frame of the guide column type welded pipe machine includes a guide column type horizontal frame, a side roller device 9, a rail 8 and a jacking wire plate structure, and the guide column type horizontal frame 7 includes a guide column type bracket, a guide column type frame side The panel 1 and the roller shaft, the roller shaft is installed on two side panels 1 of the guide column type rack, and each side panel 1 of the guide column type rack is provided with eight positioning installation holes 2, and the positioning installation holes 2 are installed on the guide column type rack. The middle of the side panel 1 of the rack is vertically and evenly arranged; the rail 8 is a square steel rail, and one side of the rail 8 is provided with a chute, and the two ends of the bottom surface of the rail chute and the connecting part of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com