Topical coating with foil

A technology of coating and carrier foil, which is applied in the field of partial coating with foil, can solve the problems of increasing the investment cost and space consumption of printing factories, and achieve the effect of flexible processing and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

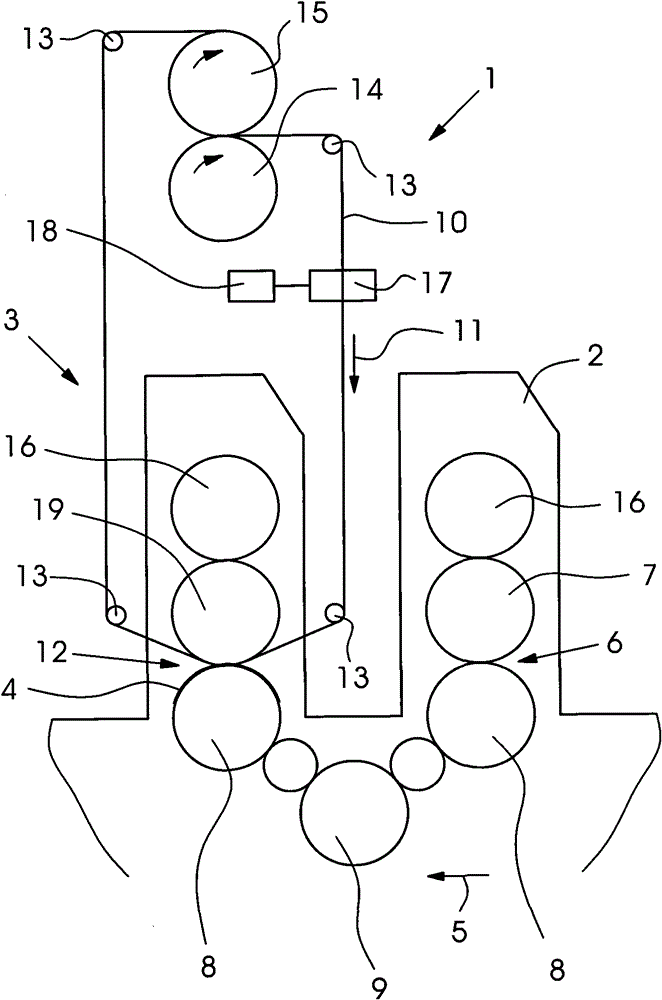

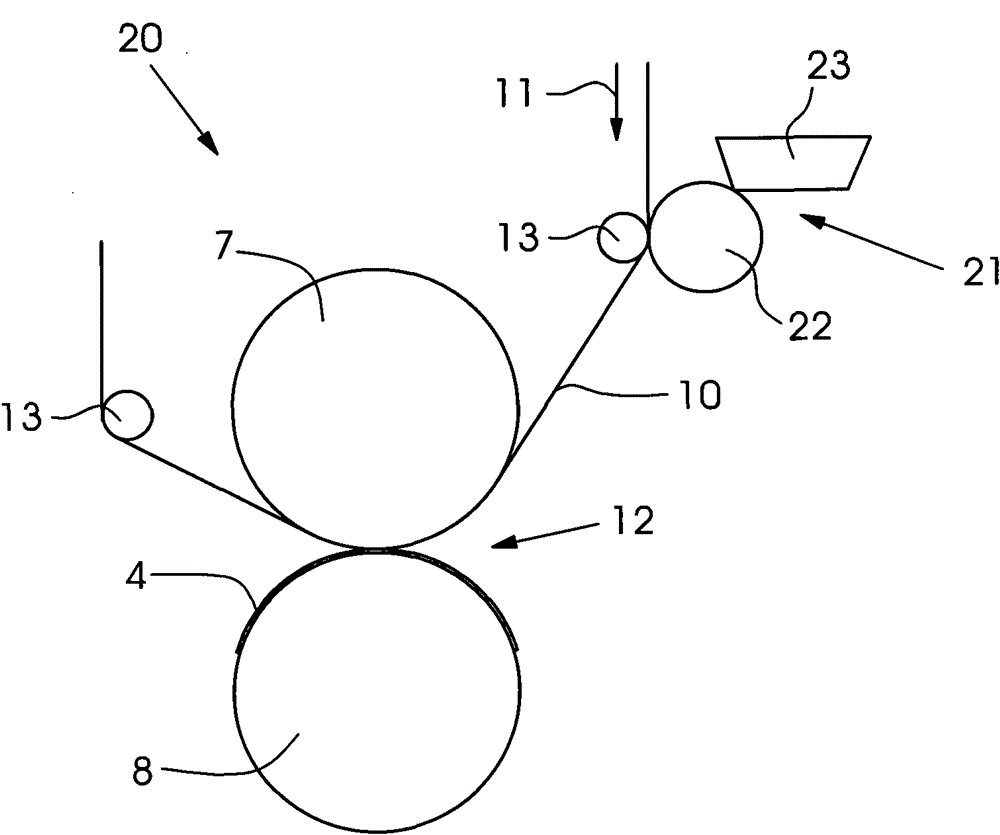

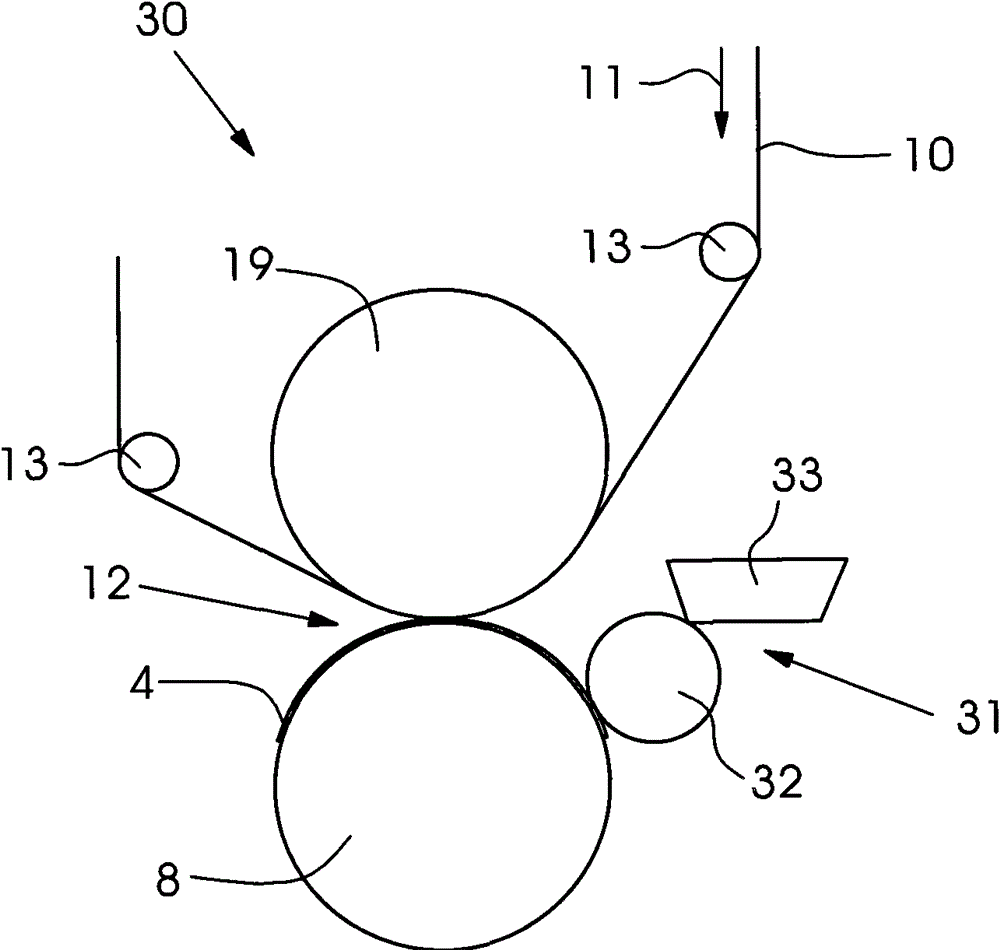

[0027] figure 1 A partial view of a lamination device 1 with an application unit 2 and a lamination unit 3 is shown.

[0028] A sheet 4 is conveyed as a substrate through the laminating device 1 in direction 5 . During this conveyance, the sheet 4 first passes through the printing nip 6 , in which the adhesive is applied to the sheet 4 at least in the region where the laminating foil 41 is to be subsequently applied. The printing nip 6 is formed by an impression cylinder 8 and a blanket cylinder 7 , which serves here as an application cylinder. Via the forme cylinder and the inking unit pressed against it, the adhesive can be transferred via the application unit 2 to the sheet 4 instead of the ink regions, as in conventional inking units of printing presses. The sheet 4 loaded with adhesive in this way is conveyed via the transfer roller 9 into the laminating unit 3 and further passes through the laminating device 1 . In the lamination unit 3 the sheets 4 are guided through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com