S-shaped laying method of double-layer submarine pipelines

A technology for a submarine pipeline and a laying method, which is applied in the directions of pipeline laying and maintenance, pipeline protection, and protection of pipelines through thermal insulation, etc., can solve the problems such as the limitation of welding speed of double-layer submarine pipelines and the reduction of the laying efficiency of double-layer and double-layer submarine pipelines. Achieve the effect of improving offshore laying rate, saving offshore construction costs and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

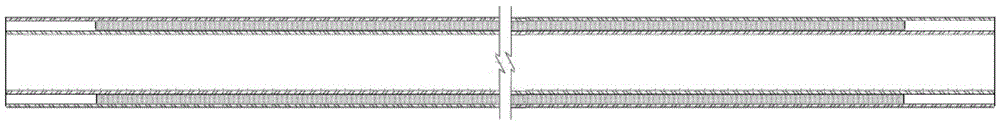

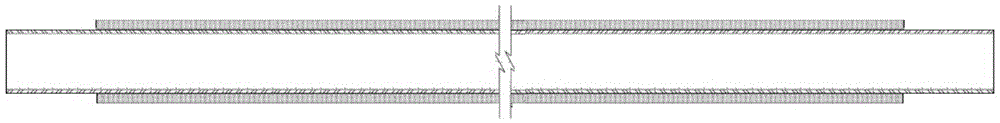

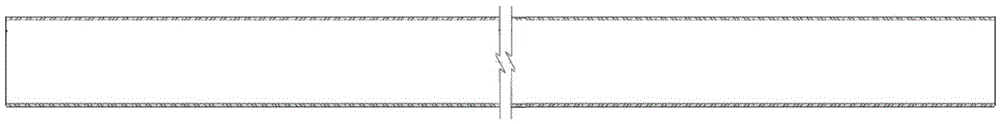

[0071] Such as figure 1 — Figure 9A Shown, the present invention adopts following sea pipe laying steps:

[0072] Step 1: Initial laying of the double-layer submarine pipeline;

[0073] 1. Transport a double-layer submarine pipeline 7 with a flange, an ordinary double-layer submarine pipeline 5 and a submarine pipeline inner tube 6 with an insulation layer to the roller 1 in the operation line, wherein the The double-deck submarine pipeline 7 with flange has one end of flange to point to the stern (as image 3 , Figure 3A shown);

[0074] 2. Place the inner pipe 6 with the insulation layer between the flanged double-layer submarine pipeline 7 and the ordinary double-layer submarine pipeline 5. At the same time, the welding point between the two pipes is located at the operation station 8, and the Station 8 for welding operations;

[0075] 3. After the welding operation of the operation station 8 is completed, the outer pipe 18 of the ordinary double-layer submarine pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com