Pipe fastening mechanism with two-ring structure

A technology for fastening mechanisms and pipes, which is applied in the direction of pipe supports, mechanical equipment, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

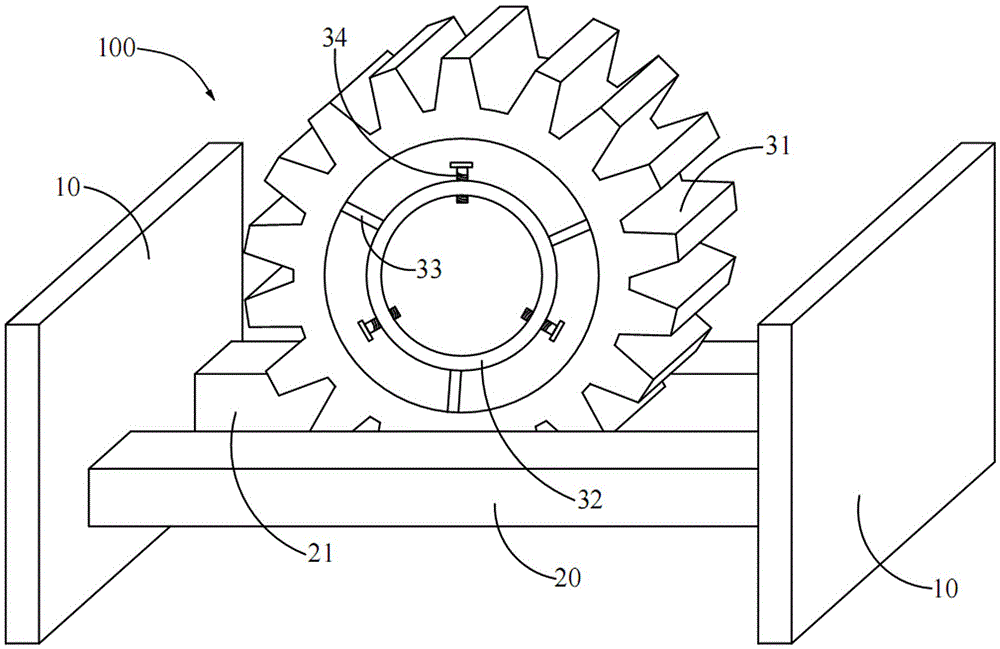

[0014] see figure 1 , the pipeline fastening mechanism 100 shown in the preferred embodiment of the present invention includes two uprights 10 , a horizontal plate 20 and a gear ring arranged between the two uprights 10 .

[0015] The two uprights 10 are vertical relative to the ground, and the two uprights 10 are arranged at intervals, and the distance between the two uprights 10 can be specifically set as required.

[0016] The horizontal board 20 is installed between the two columns 10 relatively vertically, and the horizontal board 20 is parallel to the ground. The side of the horizontal plate 20 away from the ground is provided with a groove 21 matching with the gear ring, and the two ends of the groove 21 are adjacent to the two columns 10 respectively. Internal teeth (not shown) meshed with the gear ring are provided in the groove 21 . The gear ring is rotatably installed in the groove 21 relative to the horizontal plate 20 . The axis of the gear ring is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com