Flange connecting cabin penetration pipe fitting

A technology for through-cabin pipe fittings and flanges, which is applied in the direction of flange connections, pipes/pipe joints/pipe fittings, passing elements, etc., and can solve the problem of poor sealing reliability of through-cabin pipe fittings and the easy formation of galvanic couples between ship hulls and through-cabin pipe fittings Circuit and other problems, to achieve good sealing performance, prevent corrosion, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present invention solves the technical problems of the poor sealing reliability of the tank-through tubes in the prior art and the easy formation of a galvanic couple circuit between the ship hull and the tank-through tube by providing a flange-connected tank-through tube, and realizes The technical effect of improving the sealing performance of the through-cabin pipe fittings and prolonging the service life of the ship hull is achieved.

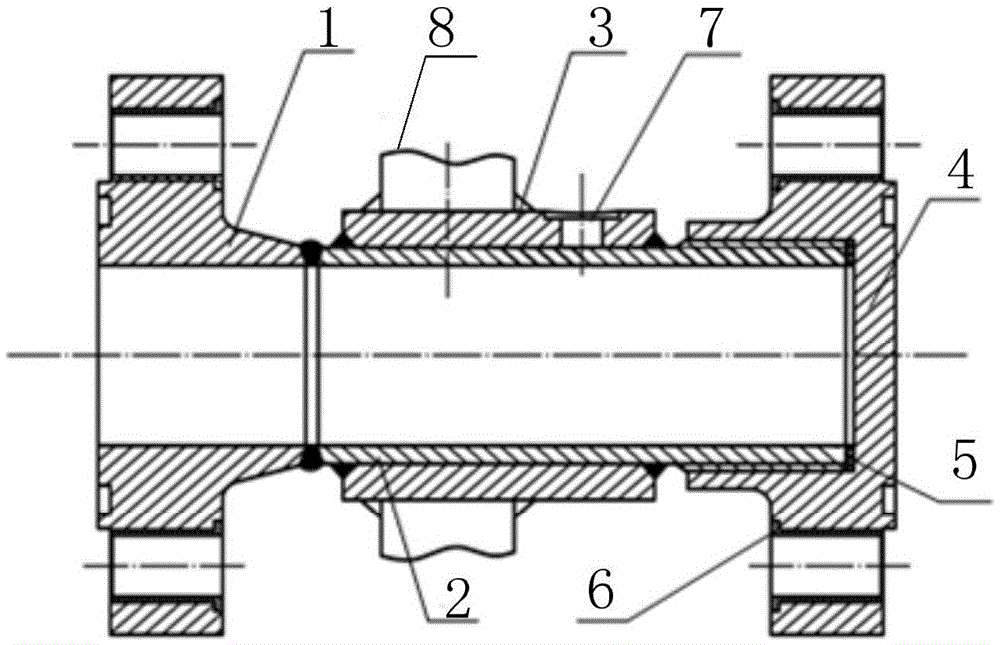

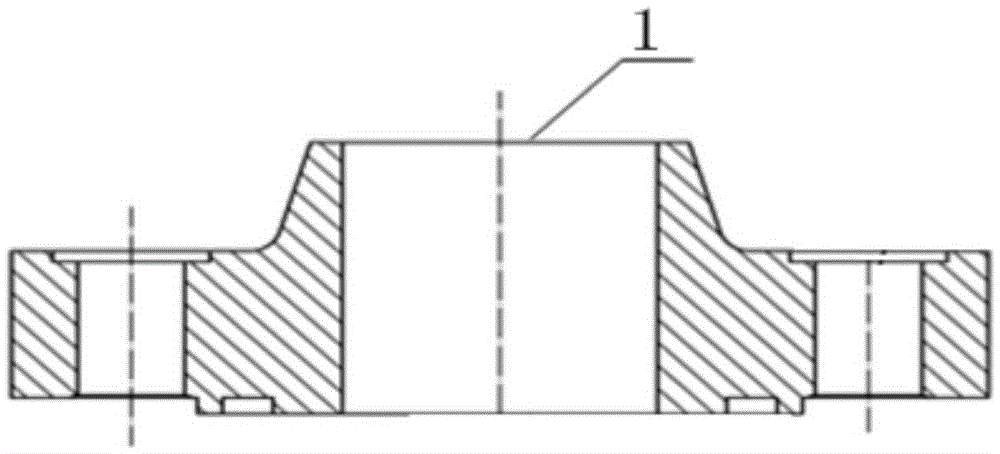

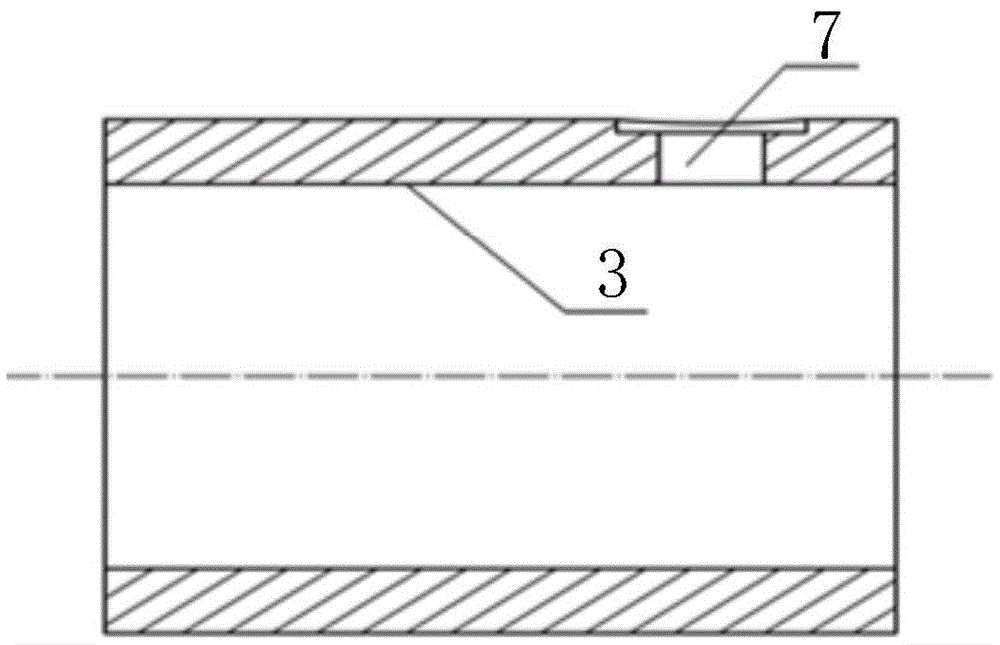

[0024] see Figure 1-Figure 5 , the embodiment of the present invention provides a flange connection through the cabin pipe fittings, the flange connection through the cabin pipe fittings applied to the hull of a ship, including: a fixed flange 1, a connecting sleeve 2, a sleeve 3, a sealing gasket 5 , Screw in the flange 4 and the insulating cylinder 6.

[0025] see figure 1 and figure 2 , the fixed flange 1 is provided with a first connection hole, the first connection hole is used to install the flange to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com