Lockable quick-fit sealing structure for small diameter tubular structure

A technology for sealing structure and structure, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc. It can solve the problems of general resilience of metal gaskets, complicated installation process, position error, etc., and achieve sealing ring deformation The effect of high volume control precision and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

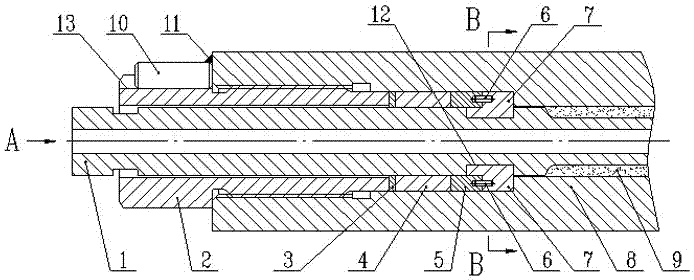

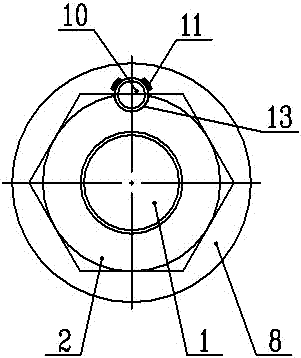

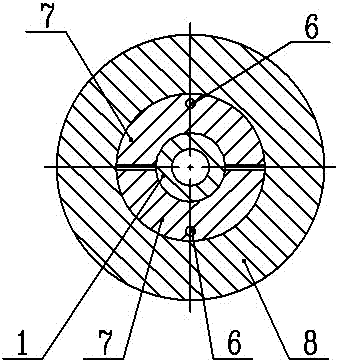

[0032] Such as Figure 1 to Figure 3 As shown, the small-diameter tubular structure uses a lockable quick-fit sealing structure, which is used for static sealing of the socket 8 at the connection point between the connecting pipe 1 and the pressure vessel or pressure pipeline, and the sealing structure includes a separating half ring 7 , sealing ring 4, hollow bolt 2;

[0033]There are at least two separated half-rings 7, and an annular groove 12 is arranged on the side where the connecting pipe 1 goes deep into the pipe seat 8, and the separating half-ring 7 is arranged in the annular groove 12, and the outer side of the separating half-ring 7 is opposite to the connecting pipe 1 The outer wall surface is convex;

[0034] The hollow bolt 2 is provided with a through hole for the connecting pipe 1 to pass through, the axis of the through hole is collinear with the axis of the hollow bolt 2, and the through hole and the connecting pipe 1 are in a clearance fit relationship;

...

Embodiment 2

[0041] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, when the sealing structure is assembled, the separation half ring 7 is embedded in the annular groove 12 by the outside of the ring groove 12, so that when the connecting pipe 1 equipped with the separation half ring 7 is inserted into the socket 8, the separation half ring The ring 7 has the risk of falling out of the annular groove 12. When the separated half-ring 7 passes through the sealing area of the tube seat 8, if it scratches the sealing surface of the sealing area, it will inevitably affect the sealing reliability of the sealing structure. , in order to eliminate the above-mentioned hidden dangers, it also includes a restricting ring 5 sleeved on the connecting pipe 1, the restricting ring 5 is located between the sealing ring 4 and the separation half-ring 7, and the end of each separation half-ring 7 close to the restricting ring 5 is At least one con...

Embodiment 3

[0049] This embodiment further limits this case on the basis of any one of the technical solutions provided by any of the above embodiments: Figure 1 to Figure 3 As shown, in order to accurately control and realize the deformation of the sealing ring 4 in the sealing state of the sealing structure, when the sealing ring 4 is in the compressed state, the end faces of the nuts of the hollow bolts 2 are in contact with the outer surface of the pipe seat 8 . In the above structure, when the separating half-ring 7 is in contact with the step surface of the step circular hole, the end of the sealing ring 4 deep into the tube seat 8 receives the supporting force, and when the hollow bolt 2 has an interaction force on the sealing ring 4, the hollow bolt 2 bolts The distance between the end face of the cap end and the pipe seat 8 is equal to the axial design compression amount of the sealing ring 4 to realize it. Namely: with this solution, the hollow bolt 2 is bonded to the pipe seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com