A gun mirror and coating method thereof

A mirror tube and gun body technology, which is applied in the direction of the muzzle attachment, launch device, etc., can solve the problems such as the position of the gun mirror shaking and the accuracy of the shell shooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

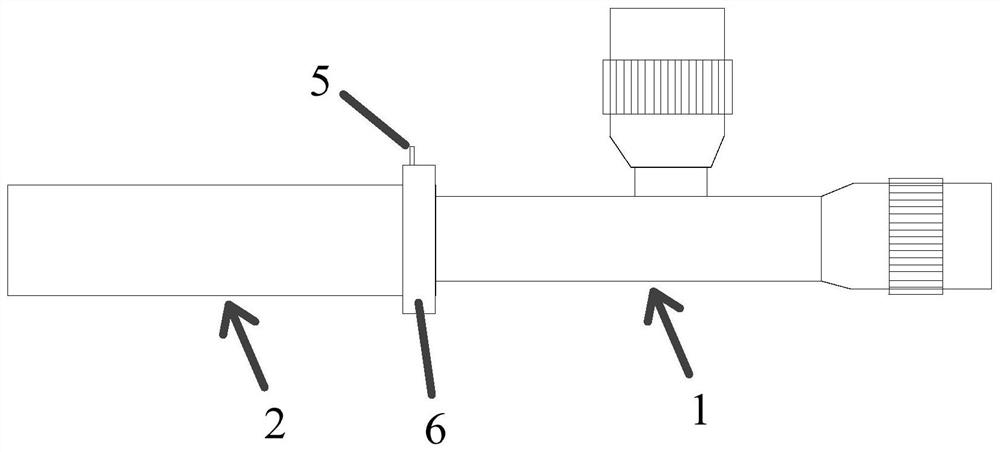

[0042] A gunscope is recorded, such as figure 1 shown, which includes:

[0043] gunscope body 1, used to observe the target;

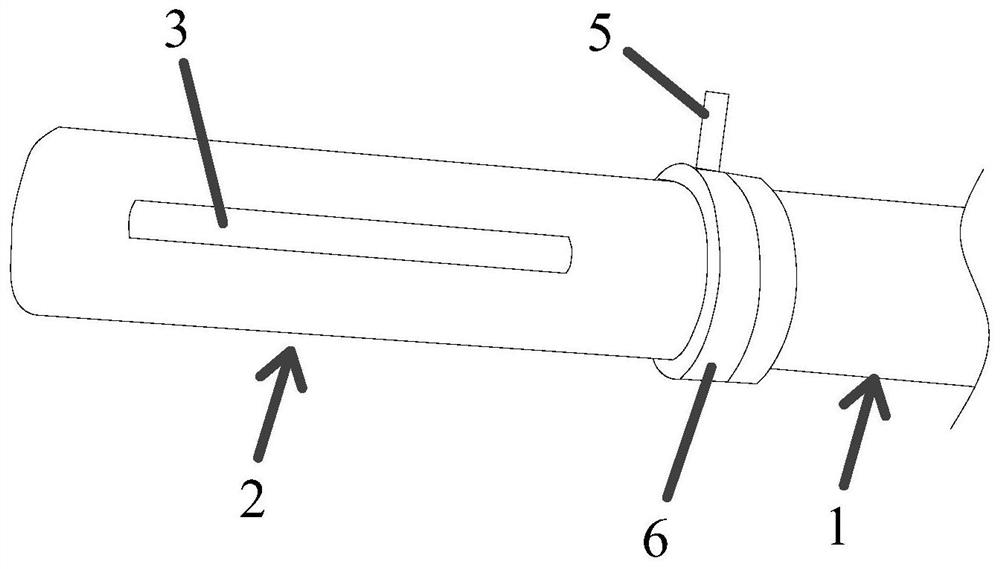

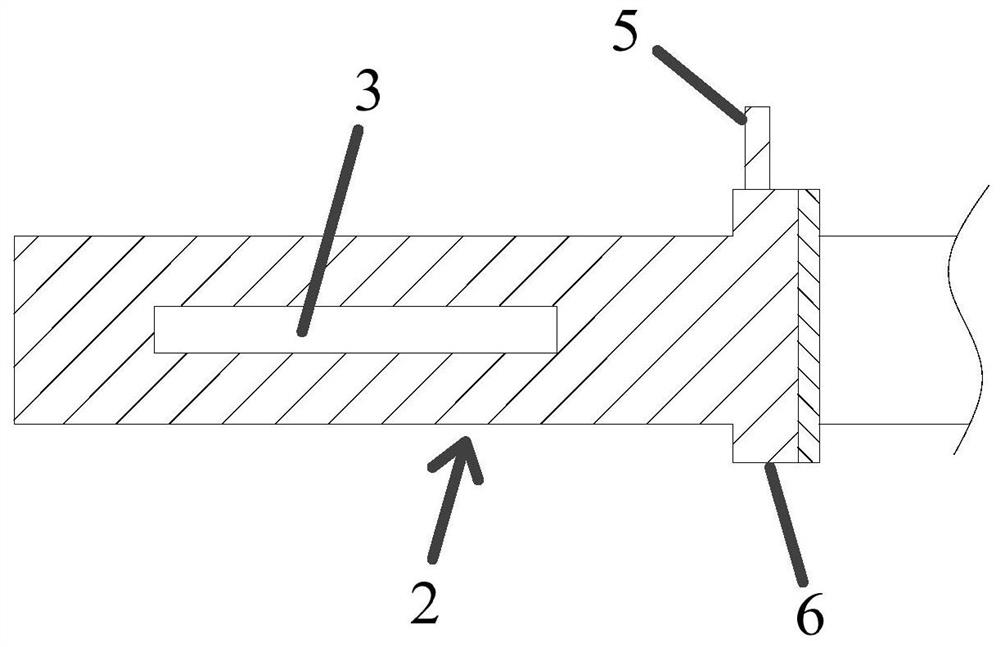

[0044] Connector 2, such as Figure 2 to Figure 4 As shown, the connecting part 2 is connected with the gunscope tube body 1, and is used to fix the gunscope tube body 1 on the gun body; the connecting part 2 is a sealed tubular cavity, and the connecting part 2. Three openings 3 are evenly arranged in the circumferential direction;

[0045] The opening 3 in this embodiment is a bar-shaped opening arranged along the length direction of the connecting portion 2 . And the three openings 3 are evenly distributed in the circumferential direction of the connecting portion 2;

[0046] Elastic expansion membrane 4, the elastic expansion membrane 4 is a rubber membrane, and the rubber membrane is attached and arranged in the connecting portion 2; when the inner cavity of the connecting portion 2 is inflated, the elastic expansion membrane 4 is released fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com