Novel cable bridge cover plate

A technology of cable tray and cover plate, applied in electrical components and other directions, can solve the problems of not easy to disassemble, damage the cable tray, reduce the performance of the cable tray, etc., to achieve convenient and quick installation, improve the performance, avoid hard collision and over The effect of heavy loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

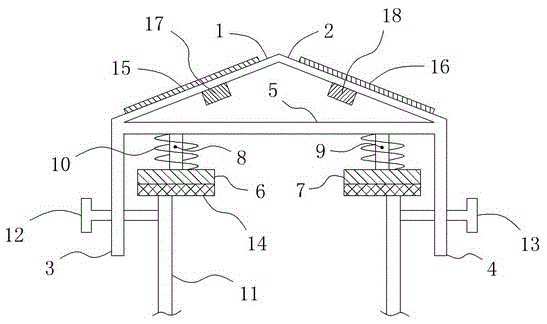

[0013] Such as figure 1 As shown, a new cable tray cover plate includes a plate body, and the plate body includes a left slant plate 1 and a right slant plate 2 fixedly connected to the right side of the left slant plate 1, and the left slant plate 1 is from left to right Extending obliquely upward, the right slant plate 2 extends obliquely downward from left to right, thereby effectively avoiding the accumulation of dropped objects on the plate body, and the left vertical plate 3 is connected vertically downward to the left side of the left slant plate 1 On the right side of the right inclined board 2, a right vertical board 4 is connected vertically downward, and at the same time, a horizontally extending front rod 5 is also connected between the top front end of the left vertical board 3 and the top front end of the right vertical board 4, Between the top rear end of the left vertical board 3 and the top rear end of the right vertical board 4 is also connected a horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com